Fracturing working method of multilevel hydraulic spraying segmentation fracturing tubular column

A technology of hydraulic jetting and staged fracturing, which is applied in drilling pipe, casing, earthwork drilling, etc., can solve the problem of increasing construction operation cycle and operation cost, not mentioning the optional setting packer, economic benefits and social benefits, etc., to achieve the effect of simple fracturing work method, reducing back splash damage and reducing pipe string creep.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

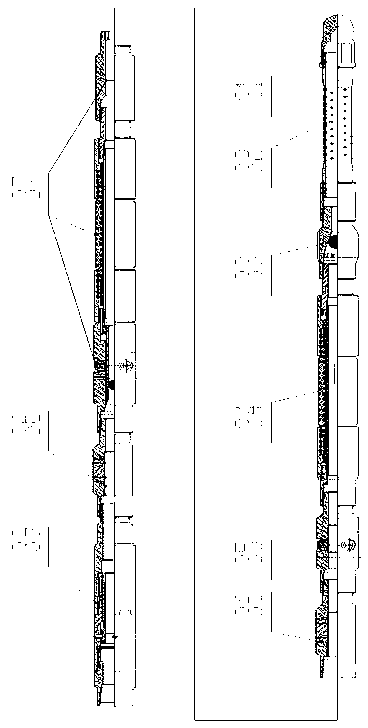

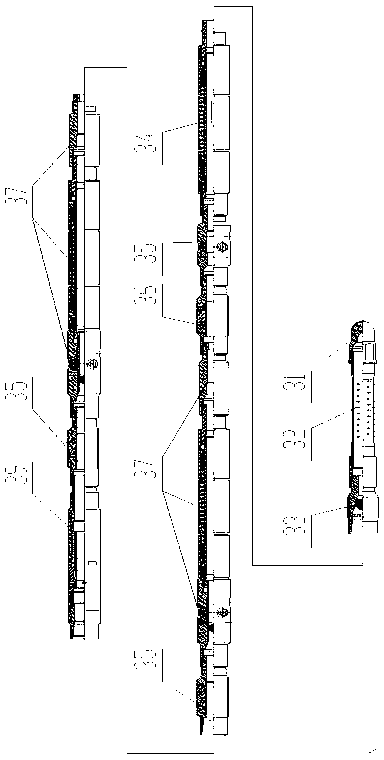

[0090] The invention discloses a fracturing working method of a multistage hydraulic jet segmental fracturing string, the steps of which are as follows:

[0091] S1: The multi-stage hydrojet staged fracturing string should be drained and washed before going into the well;

[0092] S2: Assembling multi-stage hydraulic jet staged fracturing strings;

[0093] S3: Drill down, adjust the drilling tool to the construction position;

[0094] S4: Install the wellhead and surface pipeline, and test the pressure;

[0095] S5: Construct the first stage according to the pump injection procedure designed for fracturing construction. After the construction is completed, the oil pipe will be sprayed, and after the spray potential is weakened, 600L / min reverse circulation will be used to assist drainage;

[0096] S6: Adjust the position of the drilling tool so that the injector faces the spray point of the second section of the design, and then construct the second section according to the ...

Embodiment 2

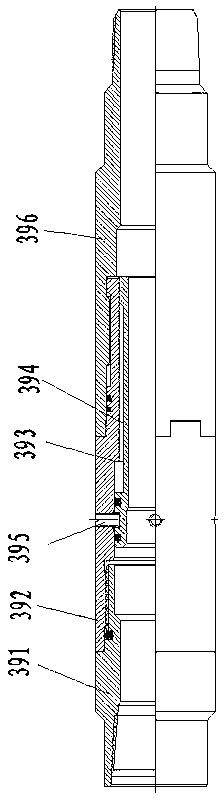

[0101] On the basis of Example 1, when the multi-stage hydraulic jet staged fracturing string is turned on, and the spray gun sandblasting and perforation in steps S5, S6, S7 and S8 are performed, the oil pressure is abnormally high, and the comparison should be checked first Interval physical properties and oil pressure during sandblasting perforation,

[0102] (1) If the physical properties of the layers are similar, and the injection pressure of each layer is abnormally high, and the casing discharge fluid is normal, it is concluded that the reason is the formation rather than the tool. The treatment method at this time: in the non-overpressure continue construction;

[0103] (2) If the physical properties between layers are similar, but the injection oil pressure between layers is large and the difference is abnormally high, it is judged that the nozzle is blocked by foreign matter or sand, and the treatment method at this time: check and adjust the liquid glue ratio in ti...

Embodiment 3

[0106] On the basis of Example 2, the oil pressure is abnormally low when the spray gun is turned on for sand blasting and perforation. First, compare it with the injection pressure of the previous layer. If the injection pressure drops significantly, it is determined that the nozzle erosion is serious. The treatment at this time method:

[0107] (1) According to the operating instructions, turn on the next "injection unit" of the tool string or pull out the drill to check and replace the tool;

[0108] (2) If there is a damaged point in the multi-stage hydraulic jet staged fracturing string, pull out the drill for inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com