Method and device for separated operation of cylinders of multi-cylinder internal combustion engine

A multi-cylinder internal combustion engine and internal combustion engine technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve the problems of unsatisfactory fuel saving effect and reduction of effective power of internal combustion engine, etc., achieve significant fuel saving effect, improve combustion conditions, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

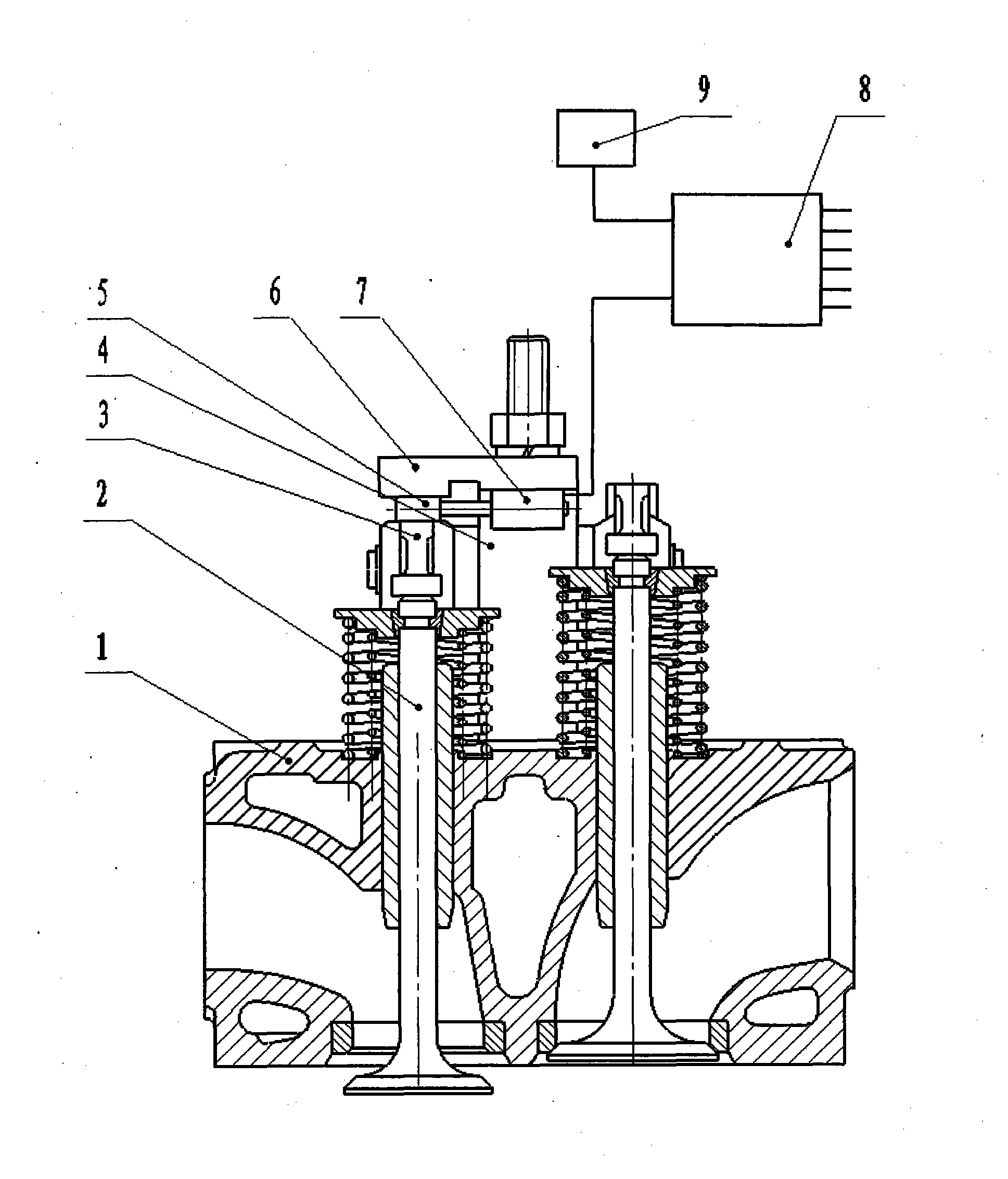

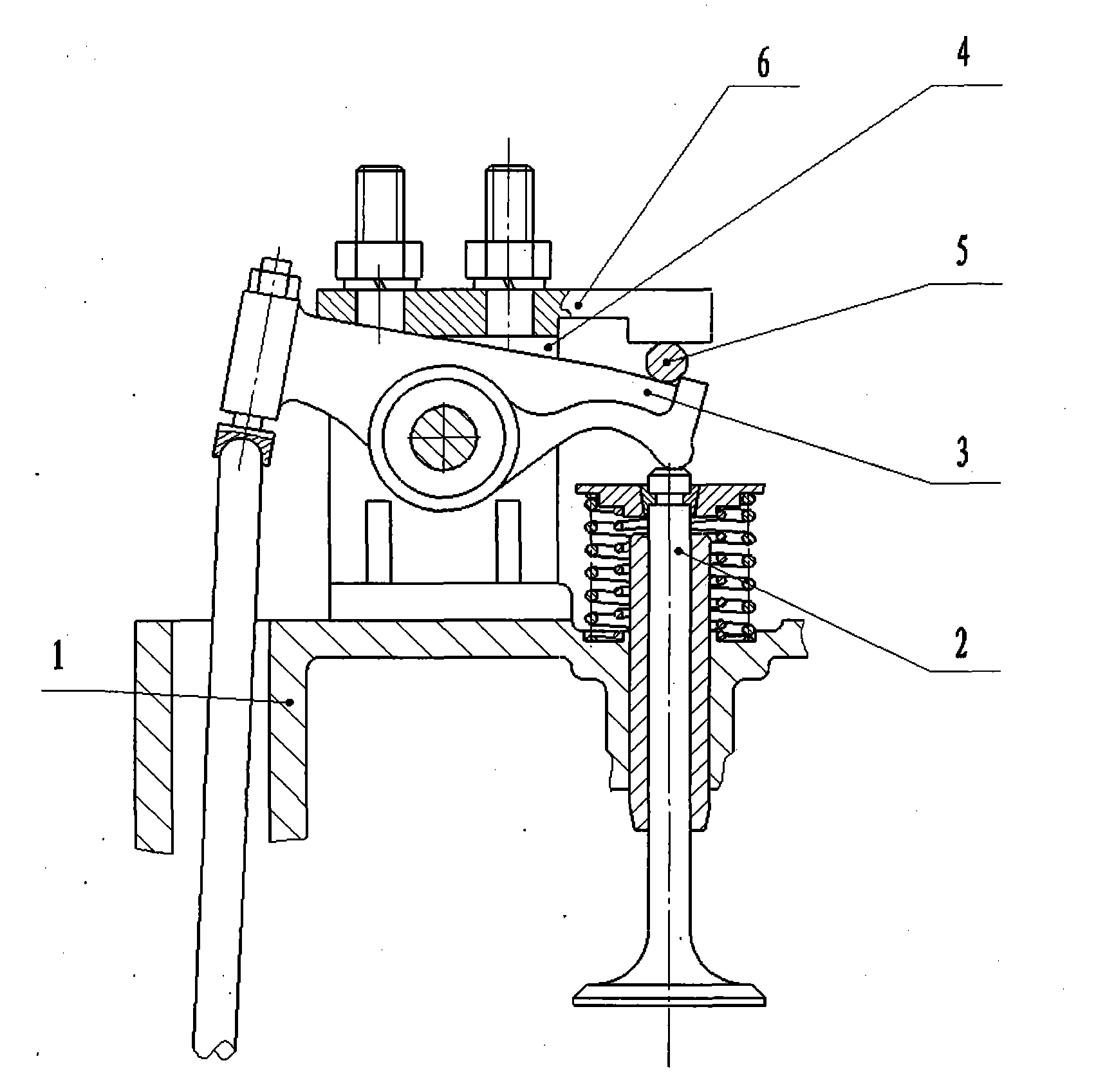

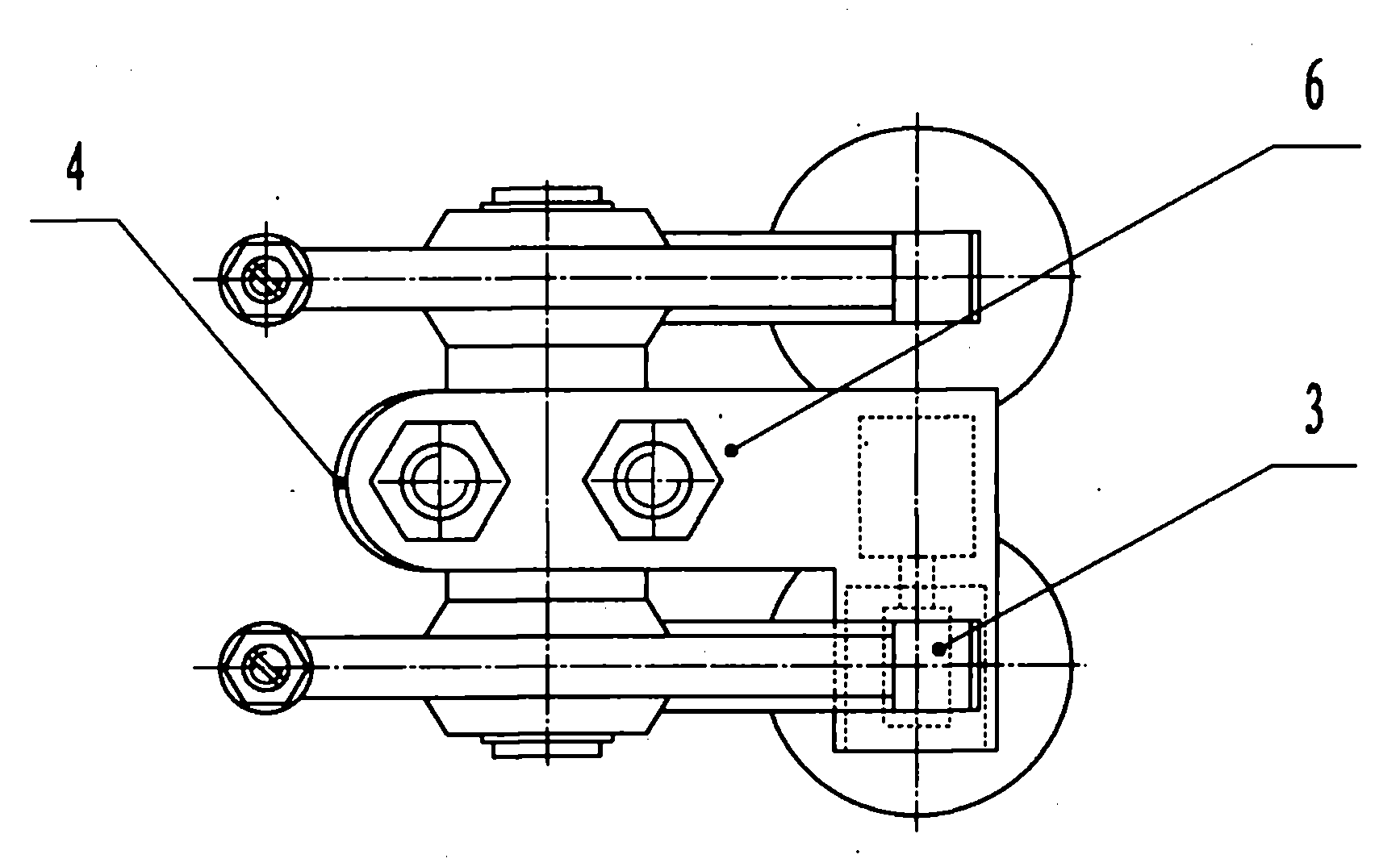

[0018] Figure 4 Among them, the upper part of the cylinder head 1 corresponds to the fixed spacer 10 under the rear part of the valve rocker arm 3, and a valve opening device is installed on one side of the spacer 10, and the valve opening device is an electromagnet 7, when all the cylinders of the internal combustion engine are used as When working in power state, the electromagnet 7 does not work. When the cylinder corresponding to the electromagnet 7 needs to be in a state of no gas compression resistance, the program control integrated module 8 sends an oil supply stop command to the oil supply device 9 corresponding to this cylinder, Send a work command to the electromagnet 7, and the oil supply device 9 stops supplying oil to this cylinder. The moving iron core 5 of the electromagnet 7 is located between the bottom of the rear part of the valve rocker arm 3 and the cushion block 10, so that the valve 2 cannot operate. In the closed position, when the piston moves up and...

Embodiment 3

[0020] Image 6 Among them, the upper part of the cylinder head 1 corresponding to the position of the valve 2 and one side of the camshaft 11 are fixedly installed with a valve opening device. The device is an electromagnet 7, and the moving iron core 5 of the electromagnet 7 is U-shaped. When all the cylinders of the internal combustion engine are When the work state is working, the electromagnet 7 does not work. When the cylinder corresponding to the electromagnet 7 needs to be in a state of no gas compression resistance, the program control integrated module 8 sends an oil supply stop command to the oil supply device 9 corresponding to this cylinder , to send a work command to the electromagnet 7, the oil supply device 9 stops supplying oil to this cylinder, and the moving iron core 5 of the electromagnet 7 is located between the valve cap 12 and the camshaft 11 above the valve 2, so that the valve 2 cannot operate In the closed position, when the piston moves up and down ...

Embodiment 4

[0022] Figure 8 Among them, the position of the upper part of the cylinder head 1 corresponding to the valve 2 and the valve chamber cover 13 are fixedly installed with a valve opening device. When the cylinder corresponding to the electromagnet 7 needs to be in a state of no gas compression resistance, the program control integrated module 8 sends an instruction to stop oil supply to the oil supply device 9 corresponding to this cylinder, and sends a work instruction to the electromagnet 7, and the oil supply device 9 Stop supplying oil to this cylinder, the force of the moving iron core 5 of the electromagnet 7 makes the valve 2 move downward, and the valve is in an open state. When the piston moves up and down in the cylinder, there is no gas compression resistance in the cylinder. There is no fuel and the valve is open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com