Method and device for improving automobile kinetic energy generating efficiency

A technology of power generation efficiency and power generation device, applied in the field of continuous power generation, can solve problems such as affecting the power generation efficiency of generators, and achieve the effects of improving power generation efficiency, improving effective vibration, and high conversion utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

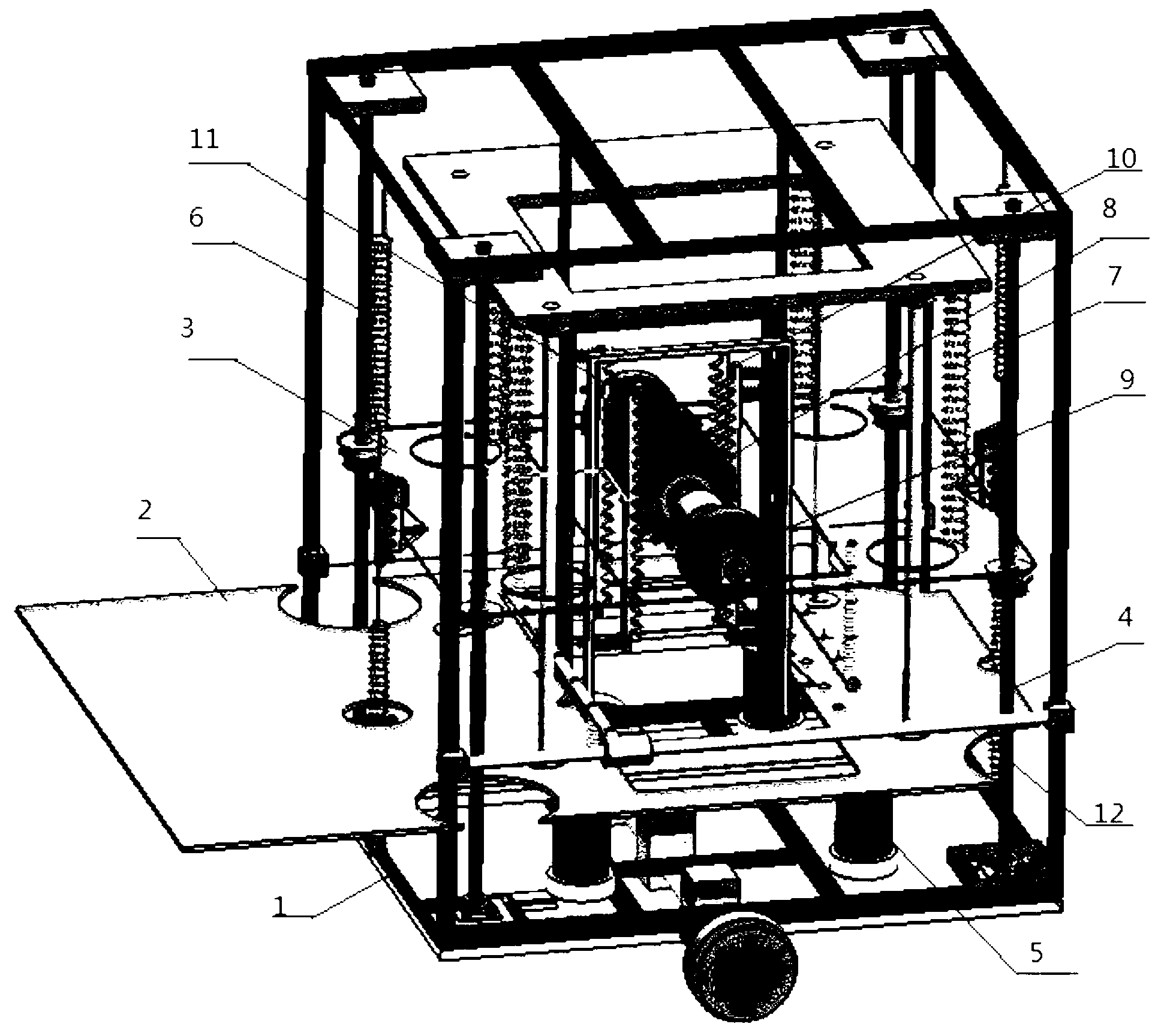

[0040] as attached figure 1 And attached figure 2 As shown, the sprung body of the automobile is provided with a vertical elastic system, and the hollow weight pallet supported by the sprung body is also provided with a vertical elastic system, and the vertical elasticity of the hollow heavy object pallet is The natural frequency of the system is set to be the same as or close to the natural frequency of the vertical elastic system of the sprung vehicle body, and a kinetic energy generating device is arranged on the hollow weight pallet, and the kinetic energy generating device includes a generator, a speed increaser 1. A plurality of gears with one-way bearings set on the rotating shaft of the generator, and a spur rack that meshes with the gears on one side. The rack and pinion components are divided into two types, one is a spur rack It is fixed on the axle frame, and the other type of spur rack is fixed on the sprung body. When the hollow weight pallet equipped with the ...

Embodiment 2

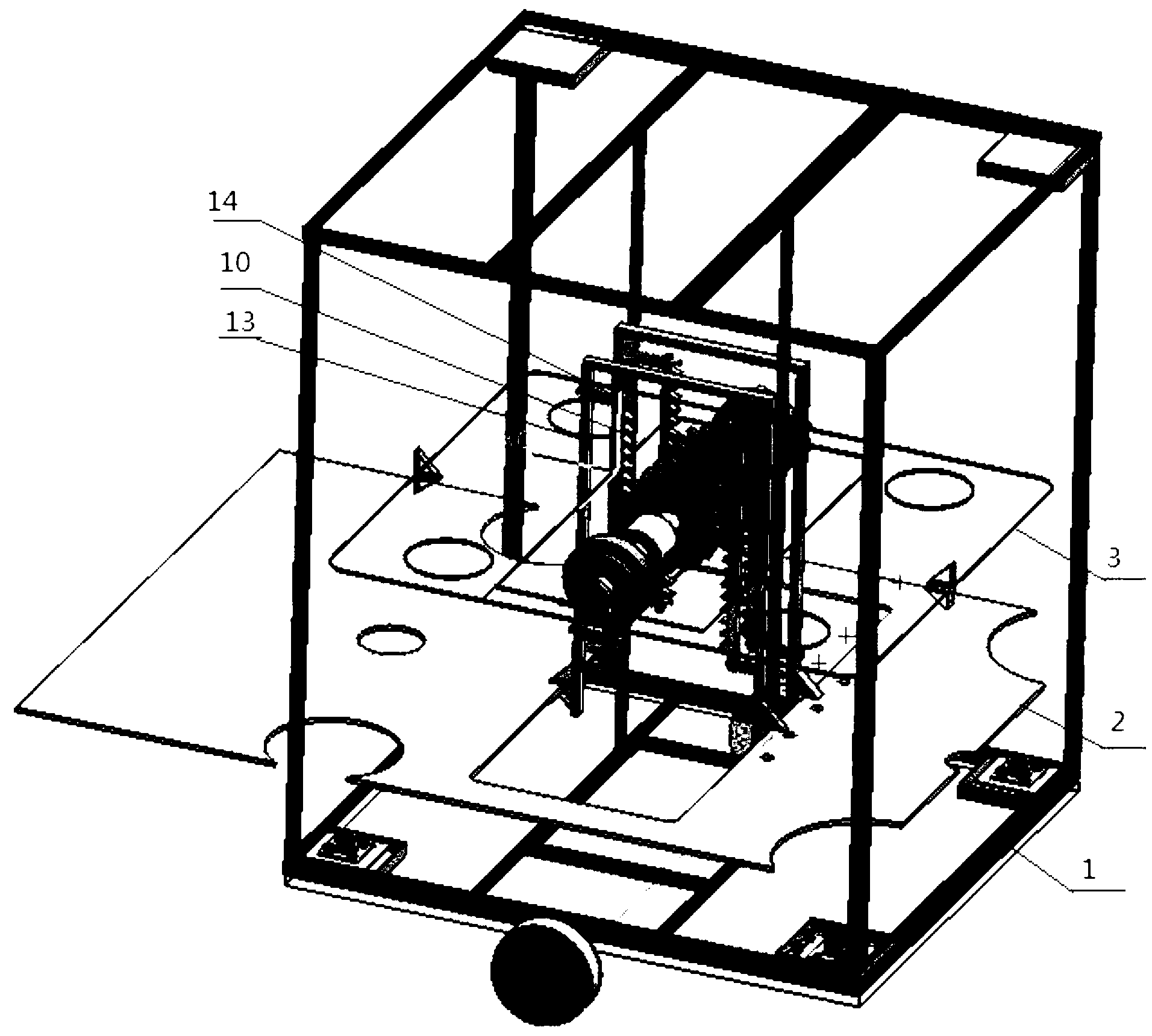

[0050] as attached image 3 And attached Figure 4 As shown, in the same frequency resonance-based automobile kinetic energy generation system as in Embodiment 1, a kinetic energy generation device is set on the sprung vehicle body, and the kinetic energy generation device also includes a generator, a speed increaser, etc., and is arranged on the generator There are a plurality of gears with one-way bearings on the rotating shaft, and a spur rack that meshes with the gear on one side. The rack and pinion group is still divided into two types. On the bridge frame, another type of spur rack is fixed on the hollow weight pallet. When the sprung body with the kinetic energy generating device vibrates up and down along the vertically fixed spur rack due to the vibration of the body, it is fixed on the hollow weight pallet. The spur rack and matching gear on the board transmit the vibration kinetic energy of frequency resonance, and the spur rack fixed on the axle frame and the mat...

Embodiment 3

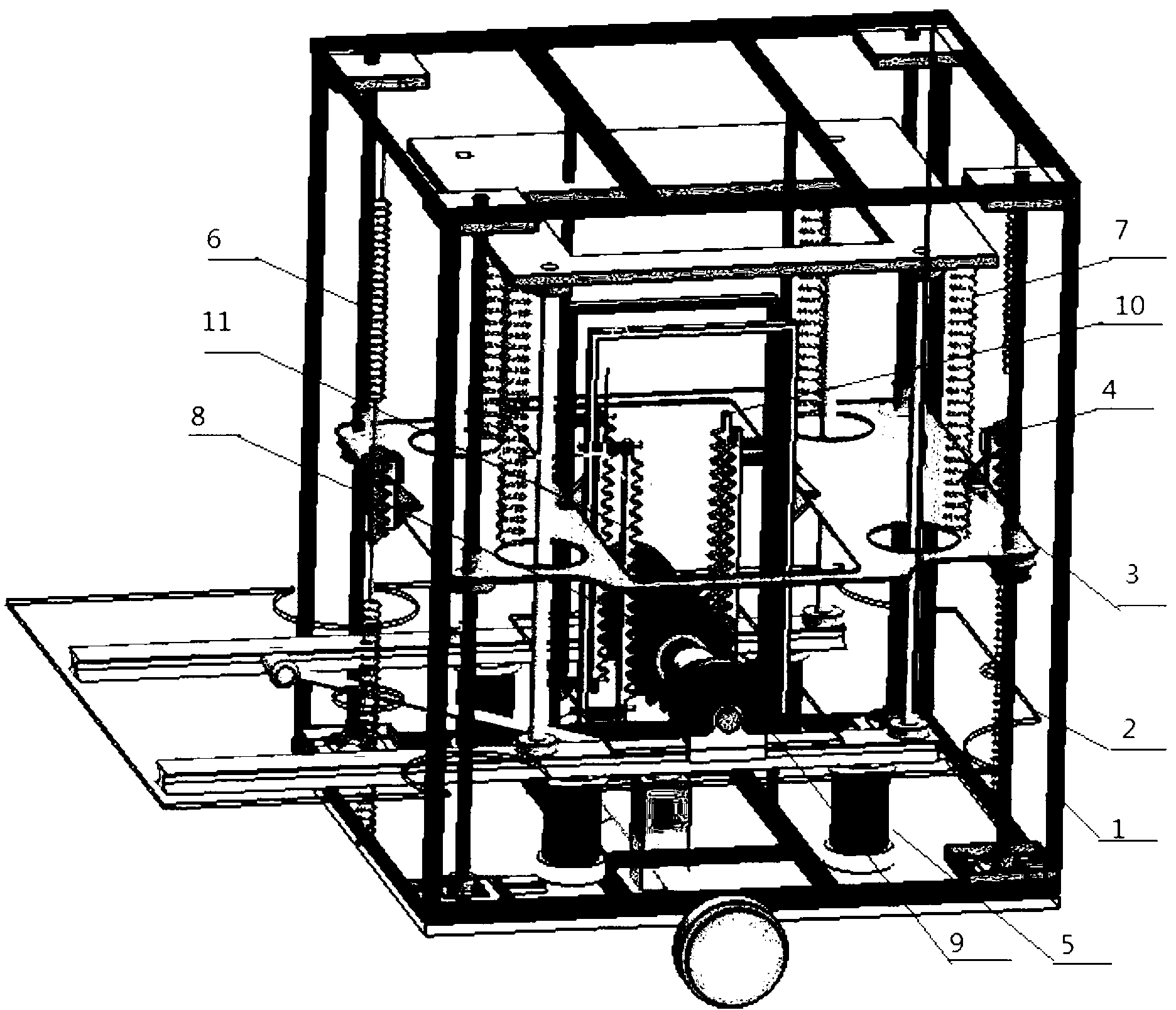

[0055] as attached Figure 5 As shown, in the same frequency resonance-based automobile kinetic energy generation system as in Embodiment 1, a kinetic energy generation device is set on the axle, and the kinetic energy generation device also includes a generator, a speed increaser, etc., and a There are multiple gears with one-way bearings on the rotating shaft, and a spur rack that meshes with the gear on one side. The rack and pinion components are divided into two types. On the body, another type of spur rack is fixed on the hollow weight pallet. When the sprung body with the kinetic energy generating device vibrates up and down along the vertically fixed straight rack due to the vibration of the body, it is fixed on the hollow weight pallet. The straight rack and matching gear transmit the vibration kinetic energy of frequency resonance, the spur rack fixed on the sprung vehicle body and the matching gear transmit the kinetic energy of direct vibration of the vehicle body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com