Device used for carrying out rope performance study on tandem type rope sheave structure

A tandem type, rope wheel technology, applied in portable hoisting devices, hoisting devices, components with teeth, etc., can solve the problems of complex analysis of rope motion performance, synchronous motion deviation, and difficulty in grasping synchronous motion laws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

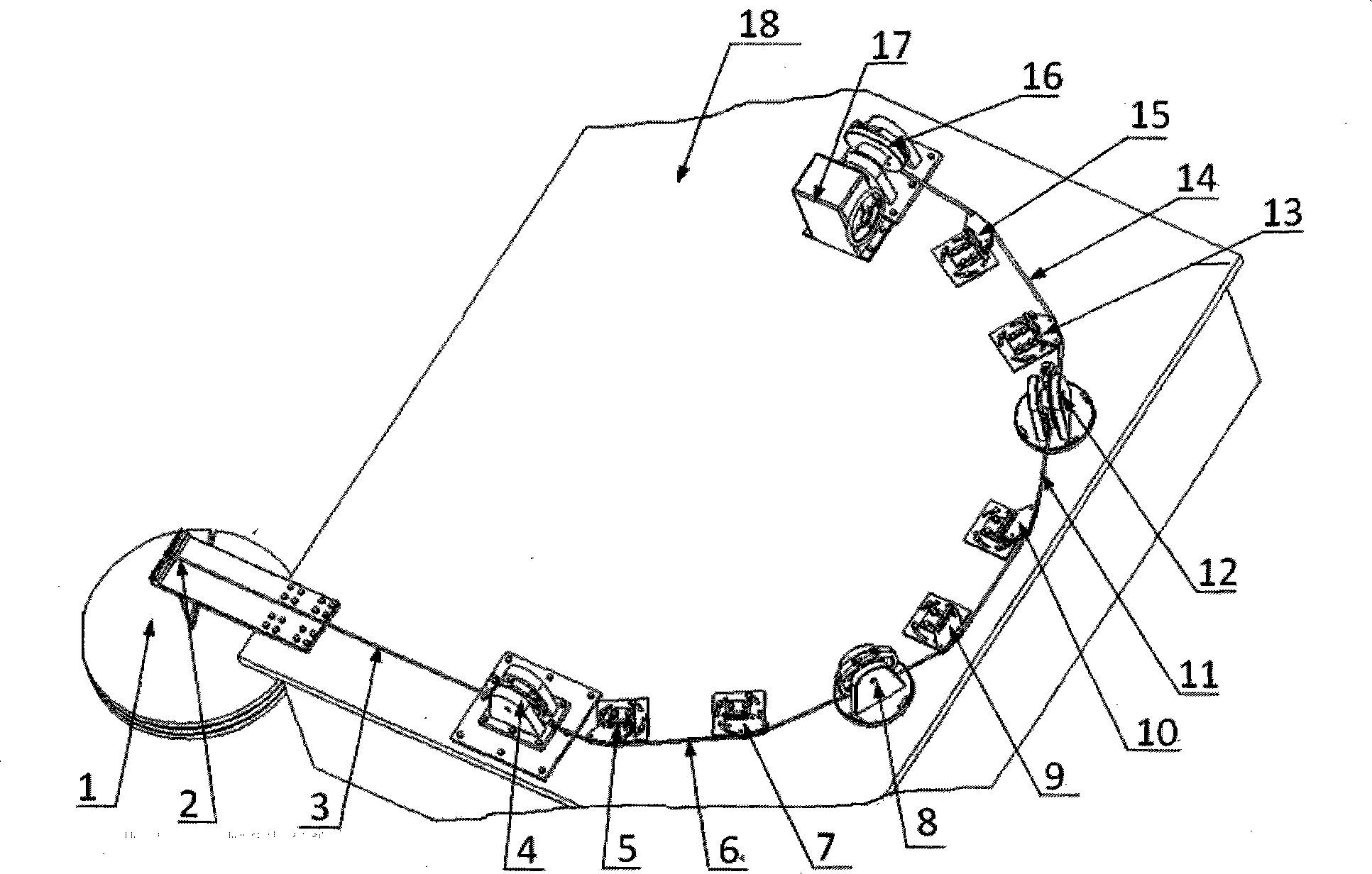

[0026] Such as figure 1 As shown, the device of the present invention for carrying out rope performance research on the tandem sheave structure includes four groups of sheave assemblies (the first sheave assembly 4, the second sheave assembly 8, the third sheave assembly 12, the fourth sheave assembly Rope wheel assembly 16), six groups of guide wheel assemblies (the first guide wheel assembly 15, the second guide wheel assembly 13, the third guide wheel assembly 10, the fourth guide wheel assembly 9, the fifth guide wheel assembly 7, the sixth guide wheel assembly Wheel assembly 5), the first rope 14 connected in sequence, the second rope 11, the third rope 6, the fourth rope 3, the counterweight 1, the guide pulley 2, and the speed reducer 17.

[0027]The six sets of sheave assemblies and the four sets of guide wheel assemblies are fixed on the workbench 18 by screws, the shaft end of the fourth sheave assembly 16 is connected with the reducer 17 through a coupling, and pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com