Lubrication slurry grouting jet nozzle used for culvert jacking

A technology of grouting and culvert, applied in the types of functional valves, valve details, control valves, etc., can solve the problems of clogging grouting pipelines and failure of grouting pipelines, and achieves reduced consumption, large installation quantity, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

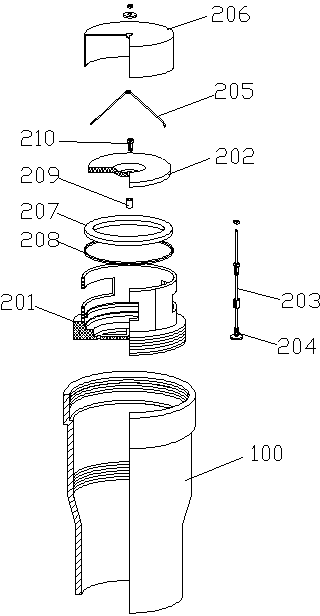

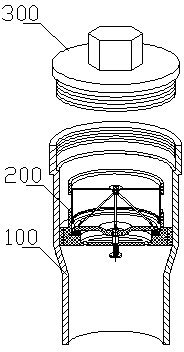

[0024] Example: such as Figure 1 to Figure 7 As shown, the lubricating grouting nozzle for the top culvert includes a casing 100, the casing 100 is a tubular structure, the diameter of the upper pipe of the casing 100 is greater than the diameter of the lower pipe, and two pipes with different diameters pass through a smooth transition. 100, the inner thread of the inner wall of the upper pipe and the middle part are respectively processed with internal threads;

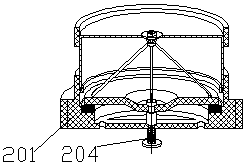

[0025] The shell 100 includes a check valve core assembly 200; the check valve core assembly 200 consists of a hard plastic valve seat 201, a soft plastic valve plate 202, a limit rod 203, a return spring 204, an elastic steel presser foot 205, and a stainless steel Mud stop 206, rubber washer 207, sealing ring 208, guide sleeve outer pipe 209 and guide sleeve core pipe 210 constitute;

[0026] The check valve core assembly 200 uses a hard plastic valve seat 201 as a support for installing other components,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com