stack burner

A burner, stacked technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of lack of gas and air preheating measures, insufficient combustion, insufficient combustion, etc., and achieve high energy utilization efficiency , Saving metal and high temperature resistant materials, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

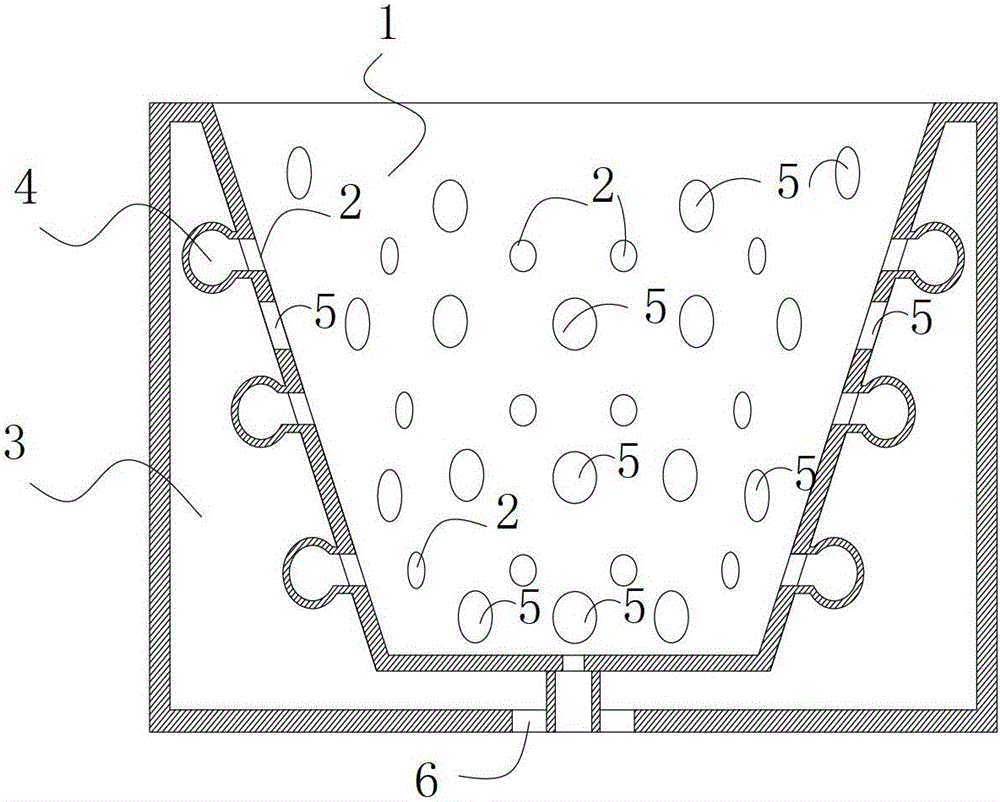

[0010] Example 1: see figure 1 .

[0011] The burner in this embodiment has a cavity-shaped combustion zone 1, and a plurality of point-shaped fuel outlets 2 are distributed in the combustion zone according to different depths. Between the inner wall of the combustion zone 1 and the outer wall of the burner is an auxiliary heating area 3, and a fuel pipeline 4 connected with a fuel outlet is arranged in the auxiliary heating area. The wall of the combustion zone 1 is provided with a plurality of through holes connecting the combustion zone and the auxiliary heating zone as air holes, and the air enters the auxiliary heating zone from the air inlet 6 at the bottom of the auxiliary heating zone to form an air passage for delivering air to the combustion zone .

[0012] The accompanying drawings are schematic diagrams, and the present invention is not limited to their proportional relationship. The introduction part of the fuel pipe in the combustor is not shown.

[0013] The...

Embodiment 2

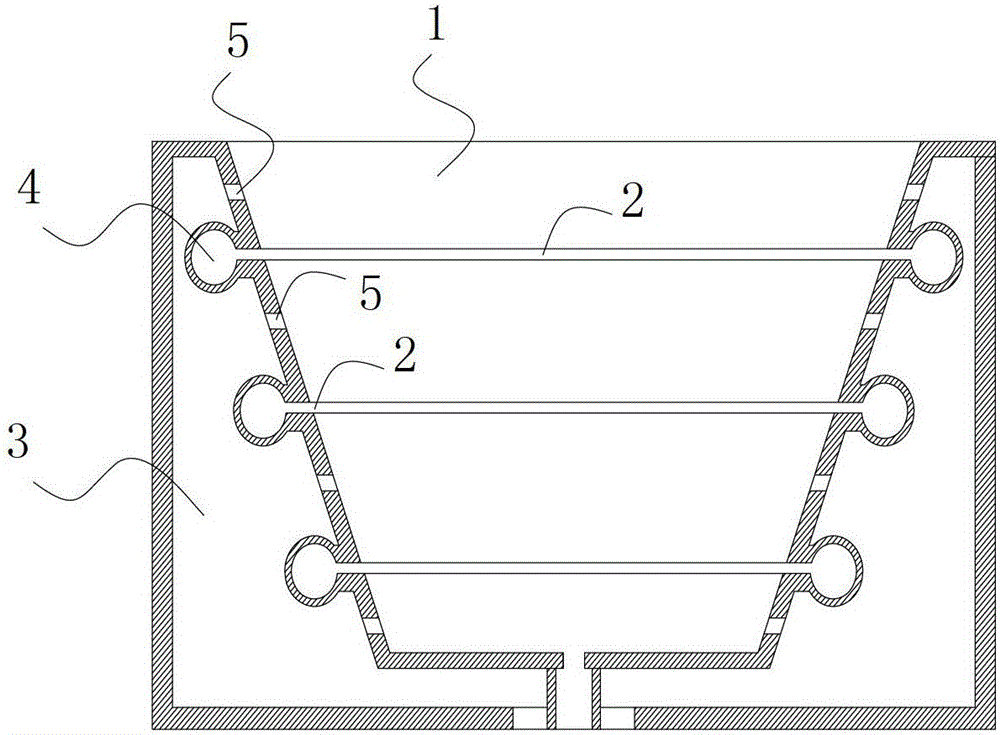

[0014] Example 2: see figure 2 .

[0015] The difference between this embodiment and Embodiment 1 is that the fuel outlet of this embodiment is a linear outlet. figure 2 Air holes are not shown.

Embodiment 3

[0017] In this embodiment, fuel pipes are arranged in a spiral shape in the auxiliary heating zone, and correspondingly, the fuel outlets in the combustion zone are point-shaped outlets arranged in a spiral shape.

[0018] In the combustion zone of the present invention, the fuel outlets are located at different depths. For non-continuous fuel outlets, such as dots (holes), the fuel outlets at the same depth are in the same layer. Even though each fuel outlet has a different depth, it is still defined by the present invention as being in a different layer. For continuous fuel outlets (linear outlets, including rings and spirals), they can be layered according to their positions in the longitudinal section. For example, a continuous helical fuel outlet, although it can be considered as only one outlet, can also constitute Multi-layer, this point is obvious to those of ordinary skill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com