Viscometer used for measuring viscosity of emu oil

A viscometer and emu oil technology, which is applied in the field of oil processing, can solve the problems of low accuracy, poor visibility of test results, failure to directly display the temperature of emu oil under test, etc., so as to improve test efficiency and reduce test cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

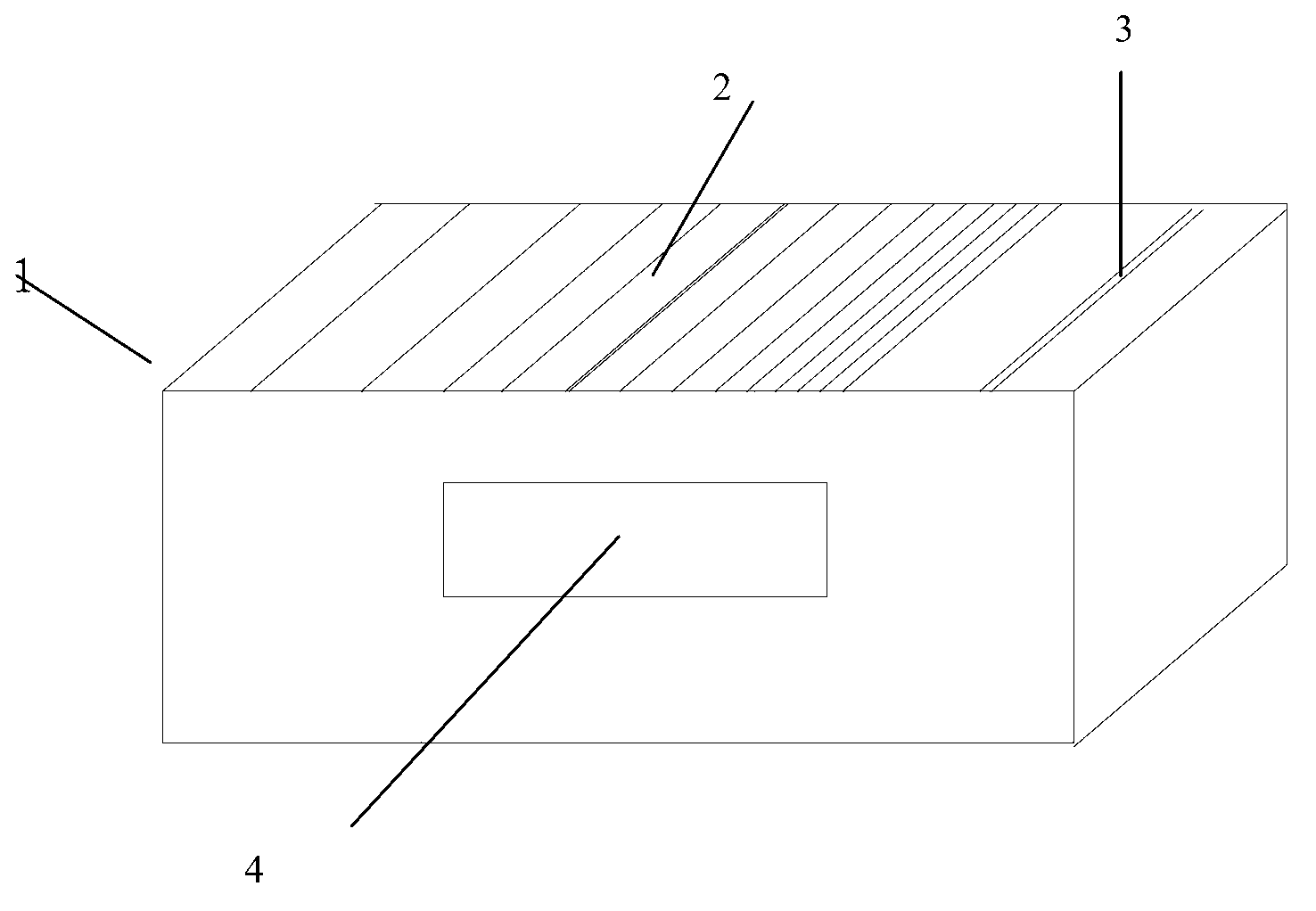

[0015] like figure 1 Shown, the viscometer that is used to measure emu oil viscosity of the present invention, comprises the box body 1 of upper opening, a plurality of fine steel wires 2 that are fixedly arranged at box body opening place and the temperature that is arranged on one side of thin steel wire at intervals in parallel For the sensor, the spacing of the thin steel wires gradually decreases, and the spacing of the steel wires changes step by step in an equal ratio. The distance between the steel wires is varied by a factor of 0.85, wherein the maximum distance is 10 mm, and the minimum distance is 0.46 mm. At the same time, a calibrated viscosity value is set at both ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com