A color filter substrate, preparation method and display device

A color film substrate and substrate technology, which is applied in optics, instruments, nonlinear optics, etc., can solve problems such as difficulty in ensuring uniformity and restrictions on the application of color film substrates, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

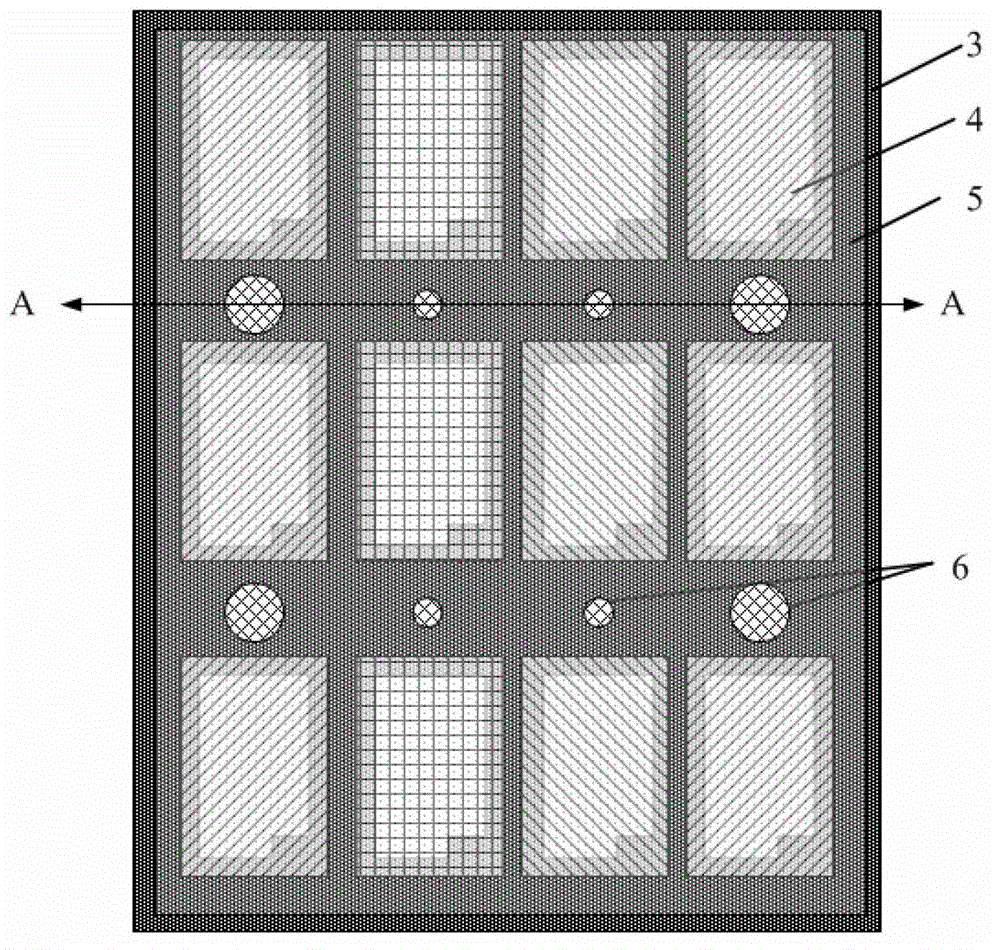

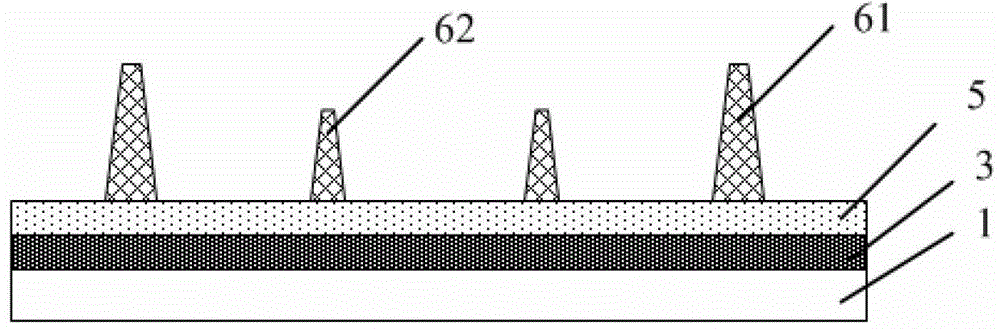

[0039] Such as image 3 , 4 As shown, a color filter substrate includes a substrate 1, a black matrix 3, a color filter layer 4, and a spacer 6. The black matrix 3 divides the substrate 1 into a plurality of sub-pixel regions distributed in a matrix, so The color filter layer 4 includes N kinds of color photoresist patterns of different colors, N≥3, and the color photoresist patterns of different colors are circularly arranged in discontinuous sub-pixel regions in adjacent N rows / columns, the The spacers 6 include main spacers 61 and sub-spacers 62, wherein the color photoresist patterns in M adjacent sub-pixel regions of a single color in at least one row / column of the color filter layer 4 are also At the same time extending to the top of the black matrix 3 between the corresponding adjacent sub-pixel regions to form a continuous strip color photoresist pattern, and the continuous strip color photoresist pattern corresponds to the top of the black matrix 3. The sub-spacer...

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 lies in that the colors of the color photoresist patterns included in the color filter layer in the color filter substrate of this embodiment are different.

[0068] In this embodiment, the N=4, the color photoresist patterns of different colors include red photoresist patterns, green photoresist patterns, blue photoresist patterns and yellow photoresist patterns, the red photoresist patterns, the The green photoresist pattern, the blue photoresist pattern and the yellow photoresist pattern are arranged cyclically in rows / columns.

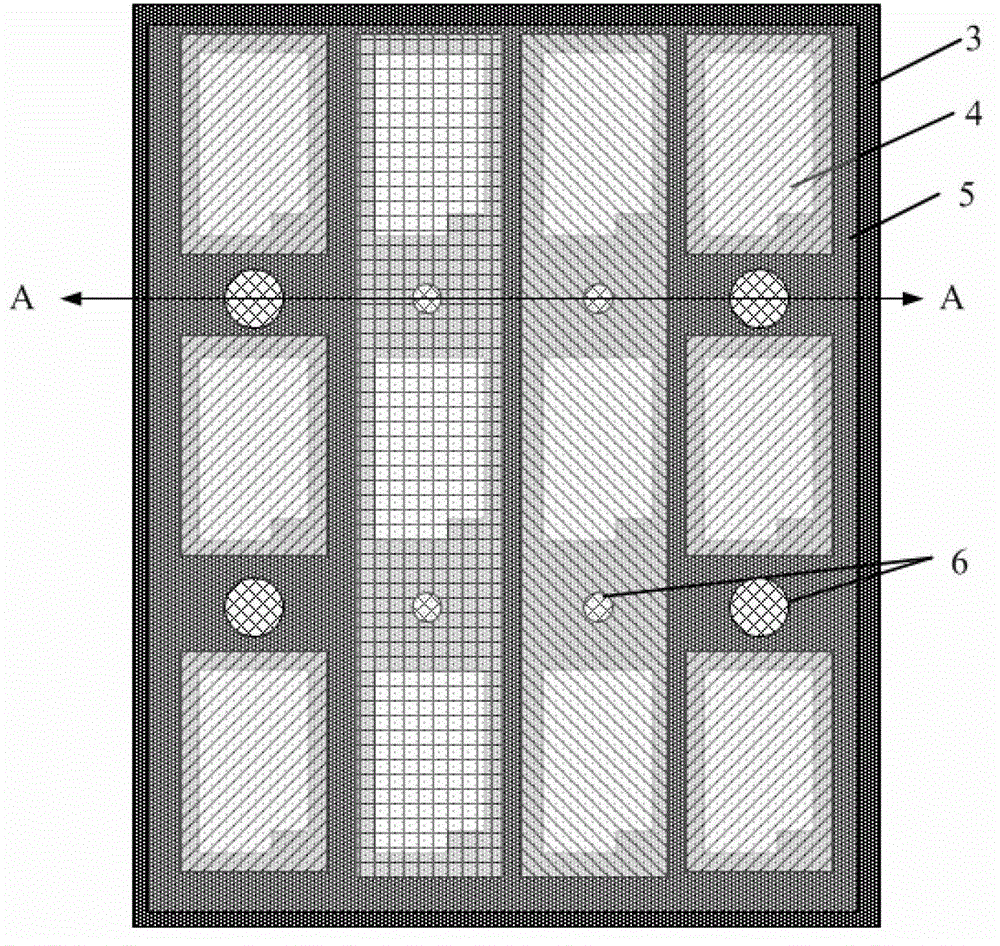

[0069] Such as Figure 7 , 8 As shown, in this embodiment, the three columns of color photoresist patterns of a single color, the green photoresist pattern, the blue photoresist pattern and the yellow photoresist pattern, are arranged in a continuous strip shape. A sub-spacer 62 that acts as a secondary support is provided above the black matrix corresponding to the yellow photoresist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com