Analog calculation method of ablating silicon nitride by ultrashort pulse laser

An ultra-short pulse laser and analog computing technology, which is applied to instruments, adaptive control, control/regulation systems, etc., can solve the problems of difficult to determine process parameters and difficult to control the removal accuracy of ultra-short pulse laser ablation of silicon nitride, etc. Achieve the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

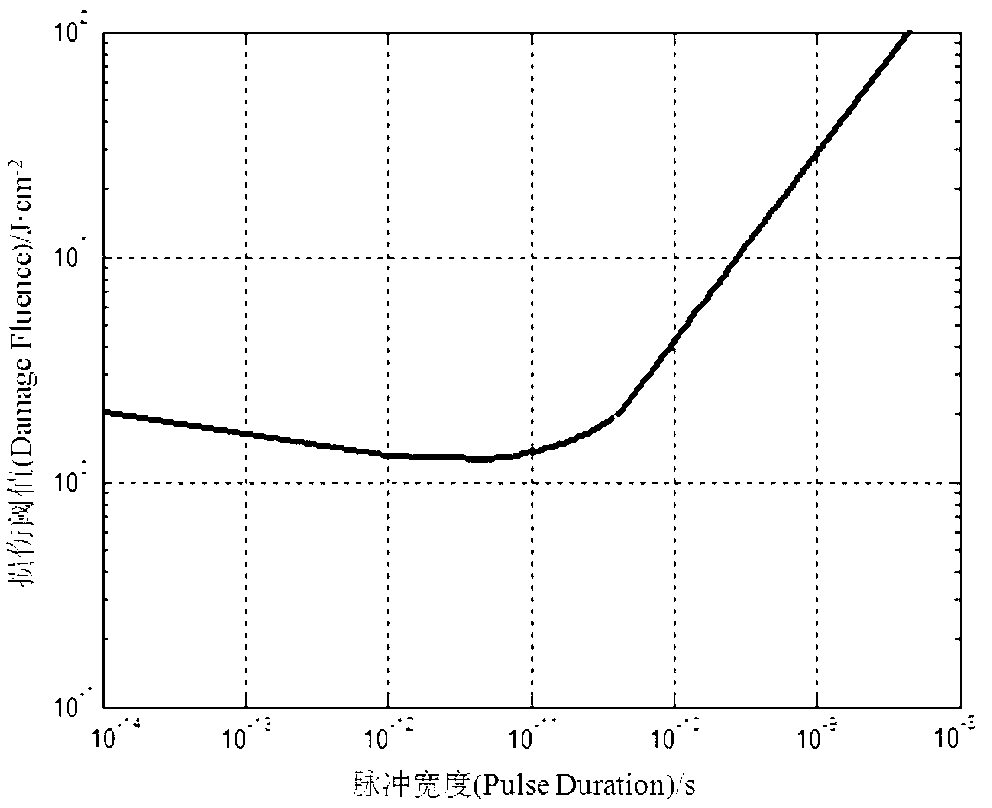

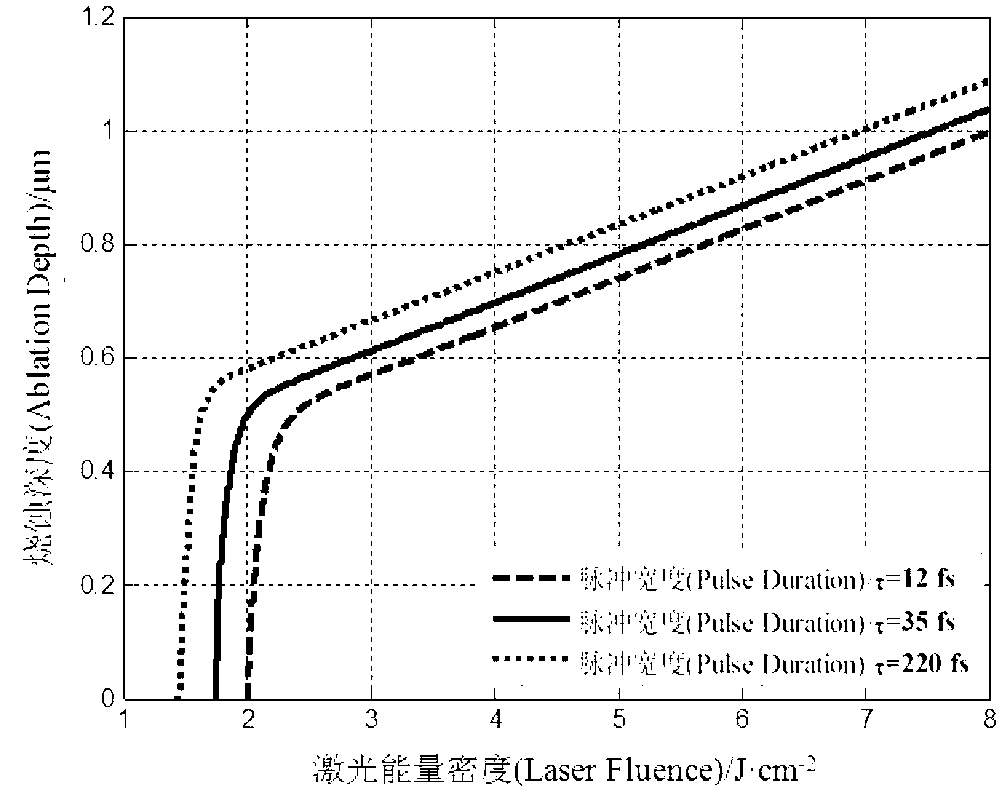

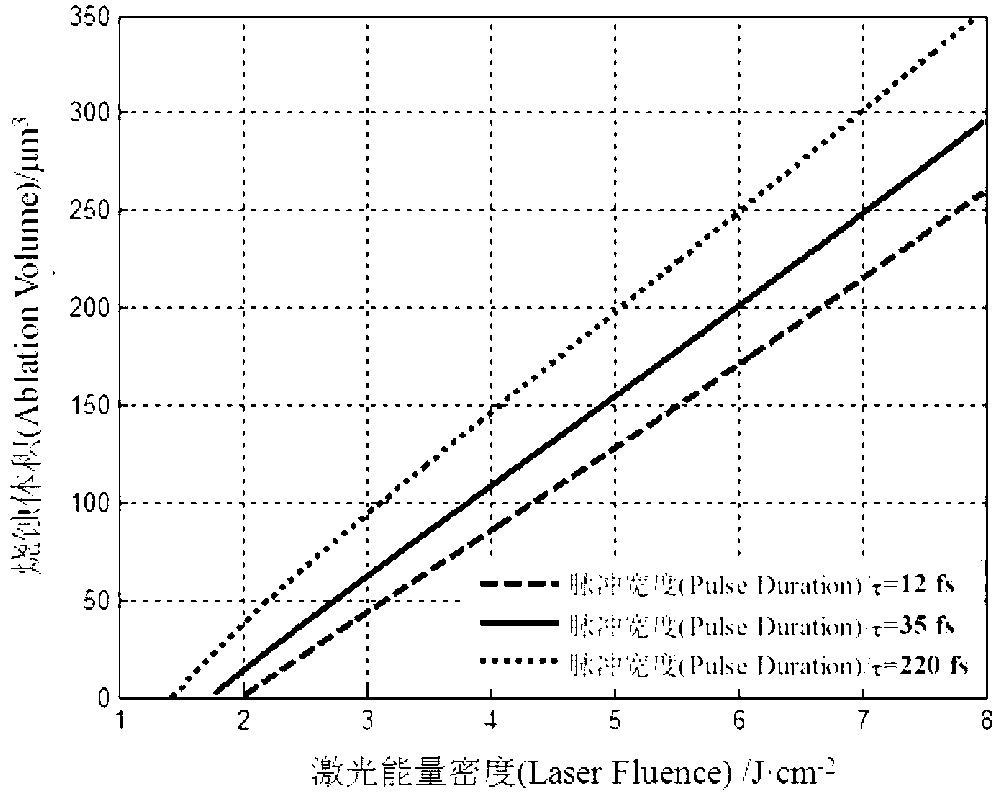

[0057] Attached below Figure 1-6 The present invention is further described with embodiment: as figure 1 As shown, a flow chart of a simulation calculation method for ultrashort pulse laser ablation of silicon nitride, the embodiment of the present invention requires: under the condition that the laser wavelength is 780nm, the process parameters used to guide the actual processing are obtained through simulation calculation. It mainly includes the damage threshold under the condition of pulse width of 10fs~10ps; the energy density is 1J / cm 2 ~8J / cm 2 , when the pulse width is 12fs, 35fs, 220fs, the ablation depth, volume and scanning speed are 0-3mm / s, and the energy density is 4.0J / cm 2 ~8.0J / cm 2 residual height at . The specific simulation calculation steps are as follows:

[0058] A. Establish the ablation threshold, depth and ablation volume model of ultrashort pulse laser ablation of silicon nitride, and initialize the parameters of the model constants. Through M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com