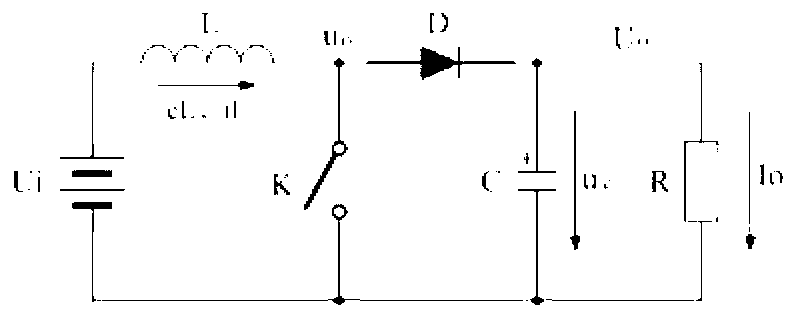

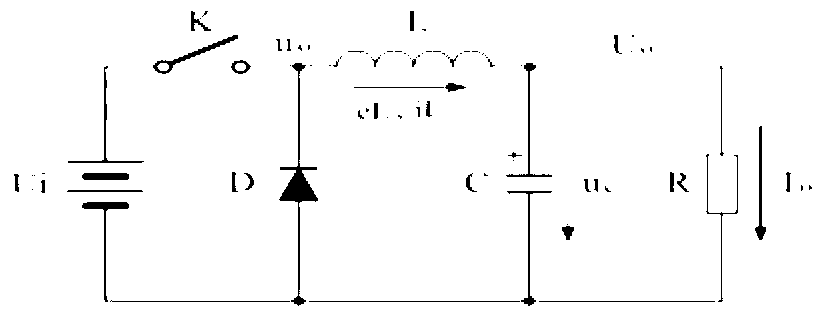

Synchronous rectification boost-buck circuit and device with parallel connection phase-shifting staggered current-sharing control

A buck-boost circuit and synchronous rectification technology, which is applied in the direction of conversion equipment without intermediate conversion to AC, can solve the problem that the buck-boost circuit is not easy to convert high-power electric energy, etc., to reduce loss and reduce energy storage requirements , to achieve the effect of overcurrent short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

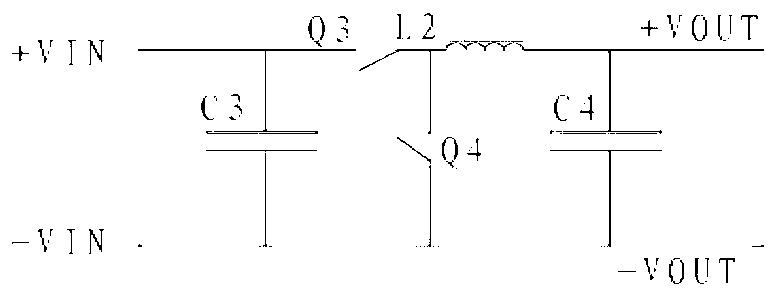

[0047] The present invention provides a synchronous rectification buck-boost circuit and device with phase-shifting interleaved parallel current sharing control, which respectively samples the inductance current of each parallel unit and provides them to their respective current controllers, and compares them with the same reference voltage after amplification so that each The peak currents of the unit inductors are evenly balanced, thereby realizing the current sharing control between parallel units. At the same time, the synchronization pulses between the controllers are phase-shifted by 90°, so that the driving pulses of each channel have a phase difference of 90°, thereby realizing the phase-shifting and interleaving control between the paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com