Texturizing lactic acid bacteria strains

A technology for texturizing lactic acid and lactic acid bacteria, applied in the direction of bacteria, Lactobacillus, Streptococcus/Lactococcus, etc., can solve the problems of not describing Bulgaria subspecies mutant strains, increasing the texture of dairy products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

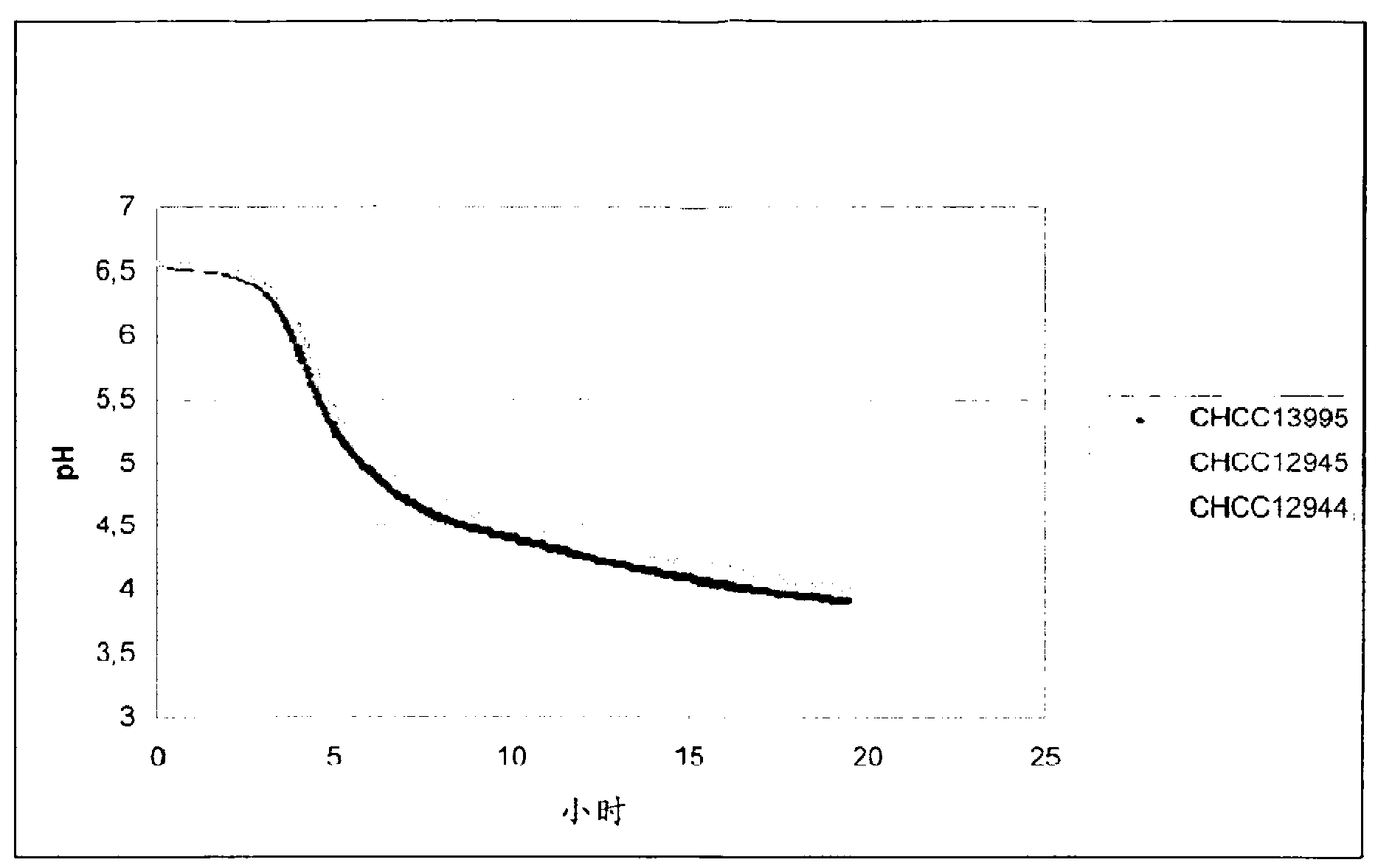

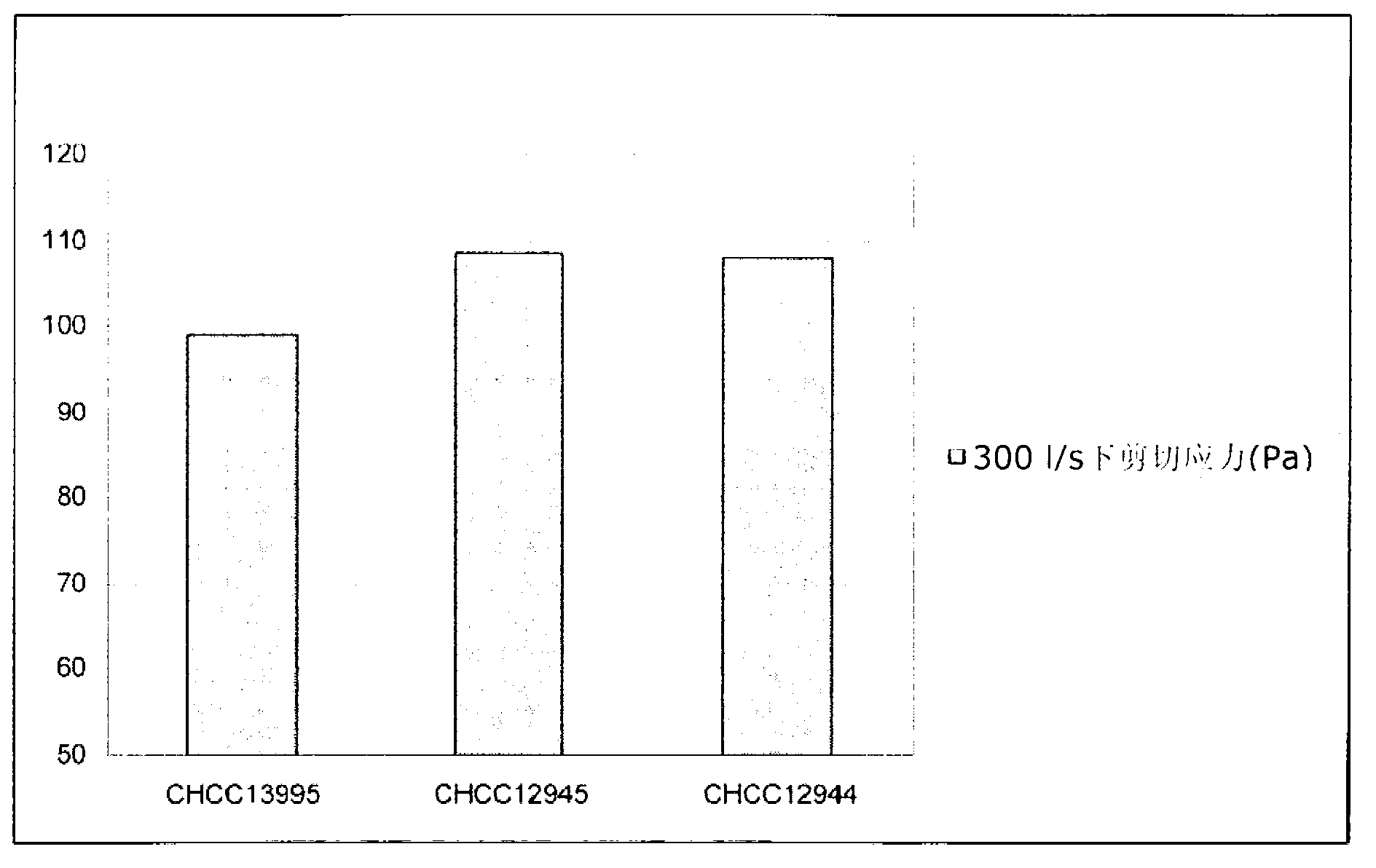

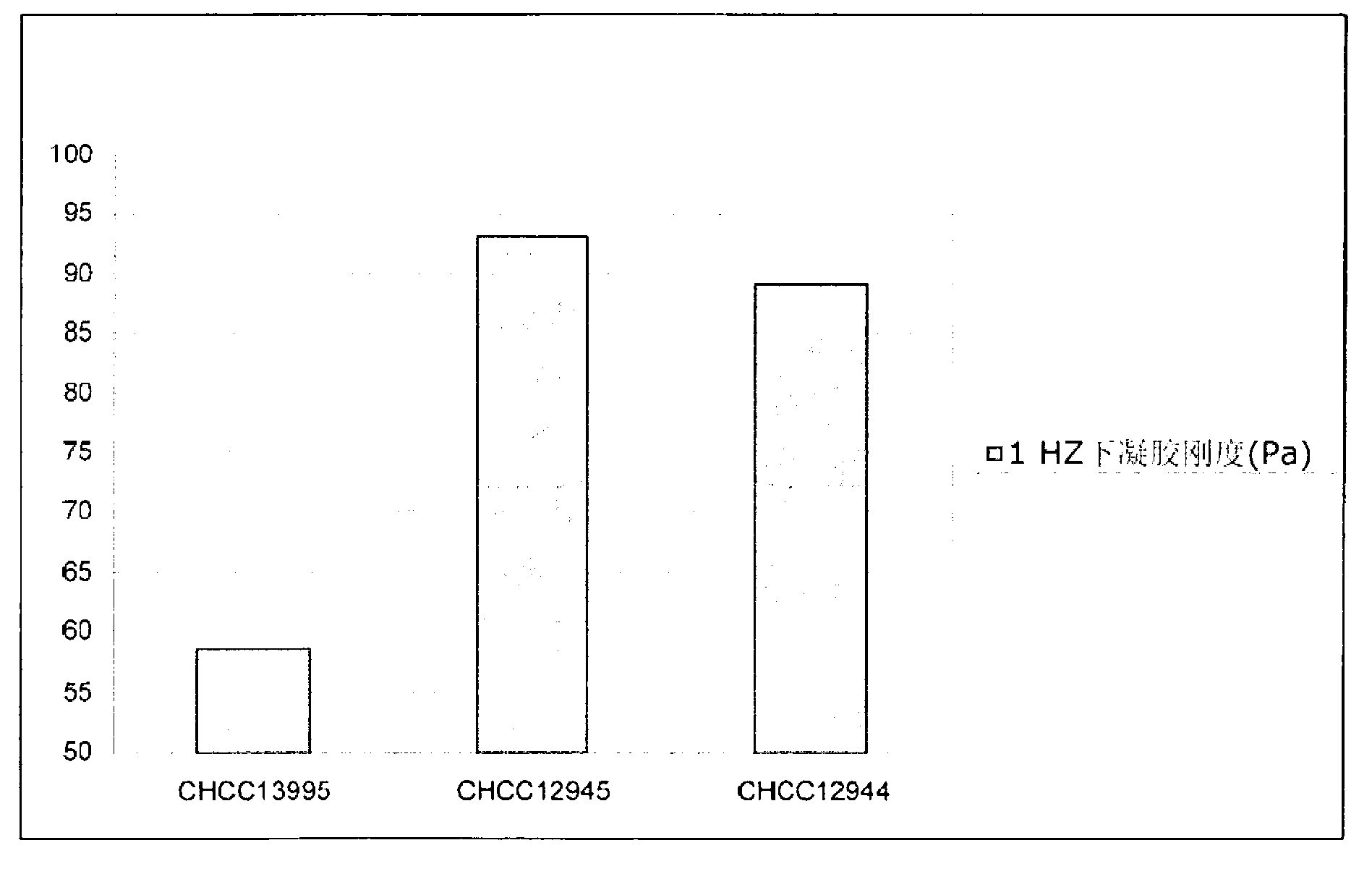

[0086] Example 1: Isolation of Lactobacillus delbrueckii progar with improved rheological properties using D-cycloserine Leah subsp. mutant

[0087] Materials and Methods

[0088] strain

[0089] Lactobacillus delbrueckii subsp. bulgaricus CHCC13995

[0090] Lactobacillus delbrueckii subsp. bulgaricus CHCC12944 (D-cycloserine resistant mutant of CHCC13995)

[0091] Lactobacillus delbrueckii subsp. bulgaricus CHCC12945 (D-cycloserine resistant mutant of CHCC13995)

[0092] Mutant isolate

[0093] To isolate mutants of Lactobacillus delbrueckii subsp. bulgaricus strain CHCC13995, cells derived from single colony growth were inoculated into MRS broth containing D-cycloserine in the range of 50-100 μg / ml and grown to saturation. Cells were diluted and plated on MRS plates and microtiter plates were screened for colonies capable of growing in the presence of D-cycloserine in the range of 50-100 μg / ml. Typically, 25% of the resulting colonies were identified as fast growing...

Embodiment 2

[0107] Example 2: Isolation of Streptococcus thermophilus mutants with improved rheological properties using D-cycloserine Change strain

[0108] Materials and Methods

[0109] strain

[0110] Streptococcus thermophilus CHCC13994

[0111] Streptococcus thermophilus CHCC13236 (D-cycloserine resistant mutant of CHCC13994)

[0112] Streptococcus thermophilus CHCC13235 (D-cycloserine resistant mutant of CHCC13994)

[0113] Mutant Isolation:

[0114] To isolate mutant strains of S. thermophilus CHCC13994, cells derived from single colony growth were inoculated into M17+2% lactose broth containing D-cycloserine in the range of 50-70 μg / ml and grown to saturation. Cells were diluted and plated on M17+2% lactose plates, picked and screened in microtiter plates for colonies capable of growing in the presence of D-cycloserine in the range of 50-70 μg / ml. Typically, 25% of the resulting colonies were identified as fast growing colonies in the presence of D-cycloserine. Select t...

Embodiment 3

[0129] Example 3: Streptococcus thermophilus and Lactobacillus delbrueckii subsp bulgaricus D-cycloserine mutants were used for Use in the preparation of fermented dairy products

[0130] Yogurt was prepared using a combination of Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus mixed in a ratio of 9:1 and inoculated into whole cow's milk supplemented with 2% skim milk powder. One mixture contained the parental strains CHCC13994 and CHCC13995; the second mixture contained the S. thermophilus D-cycloserine mutant CHCC13236 and the L. delbrueckii subsp. bulgaricus D-cycloserine mutant CHCC12945, and the third mixture contained the thermophilic chain Coccus D-cycloserine mutant CHCC13235 and Lactobacillus delbrueckii subsp. bulgaricus D-cycloserine mutant CHCC12945. A comparison of the acidification properties between these three combinations showed that the mixture with the two mutant strains had a slightly higher final pH than the combination with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com