Axial fan

A technology of axial flow and fan, applied in axial flow pumps, non-variable pumps, non-displacement pumps, etc., can solve the problems of efficiency reduction and achieve improved fan efficiency, reduced sound pressure level, and increased volume flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

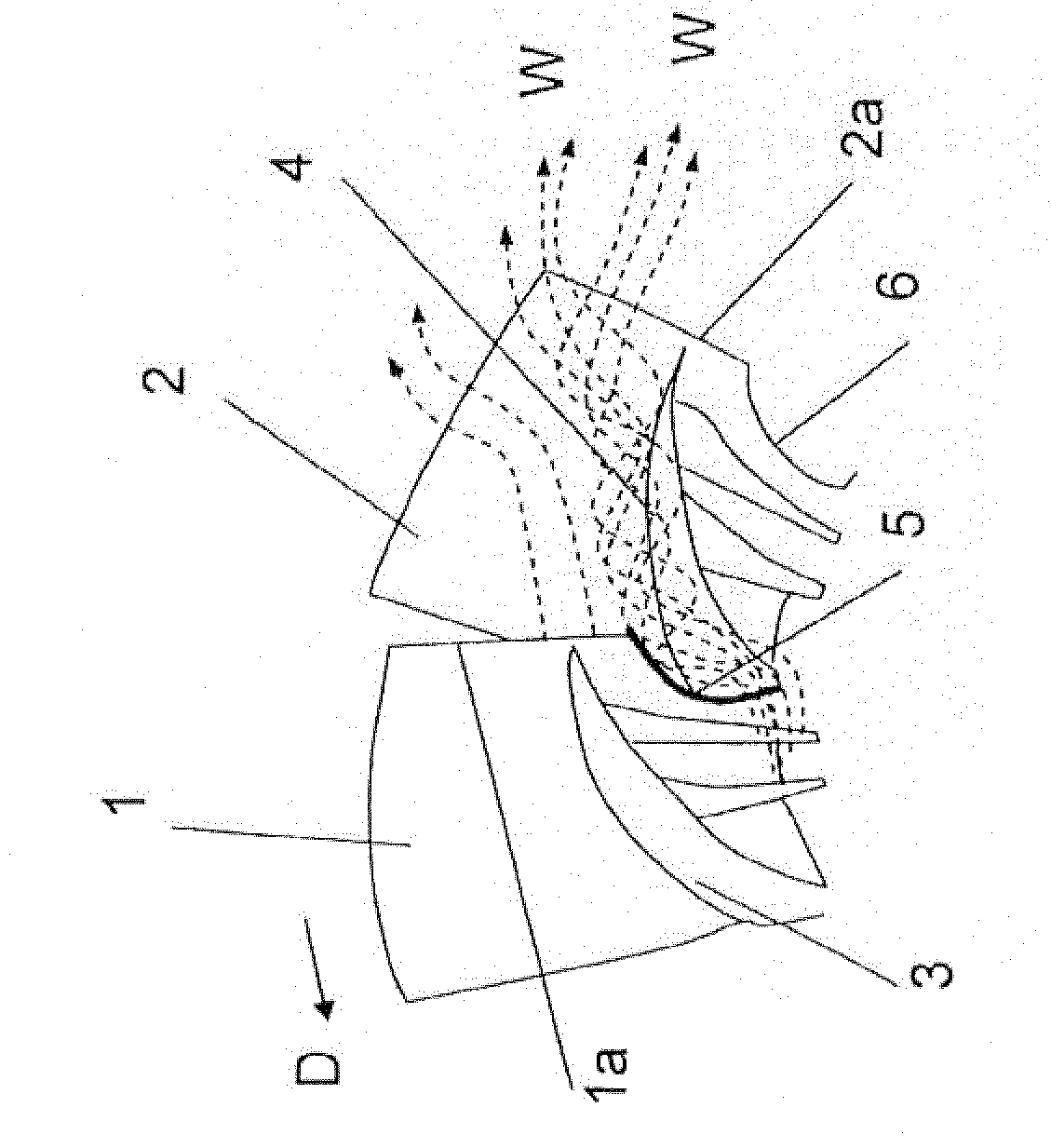

[0027] Fig. 1 shows the arrangement of fan blades 1, 2 of an axial fan according to the prior art. The direction of rotation of the fan is indicated by arrow D. The fan blades 1 , 2 each have a hub ramp 3 , 4 and a blade trailing edge 1 a , 2 a on their pressure side. The rear edges (or also called outlet edges) 1 a , 2 a each have a notch or groove 5 , 6 in their radially inner region (ie in the hub bevel 3 , 4 ). Such a recess and a reduction in the width of the fan blade is carried out in the prior art because on the one hand it means saving weight and on the other hand it is considered that the fan blade no longer provides a power gain in the area of the blade root. However, crossflow and / or backflow have proven to be disadvantageous. The circulation through the blade trailing edge in the groove 5 produces a vortex trail indicated by the arrow W, which leads to a reduction in fan efficiency, a reduction in the volume flow and an increase in noise.

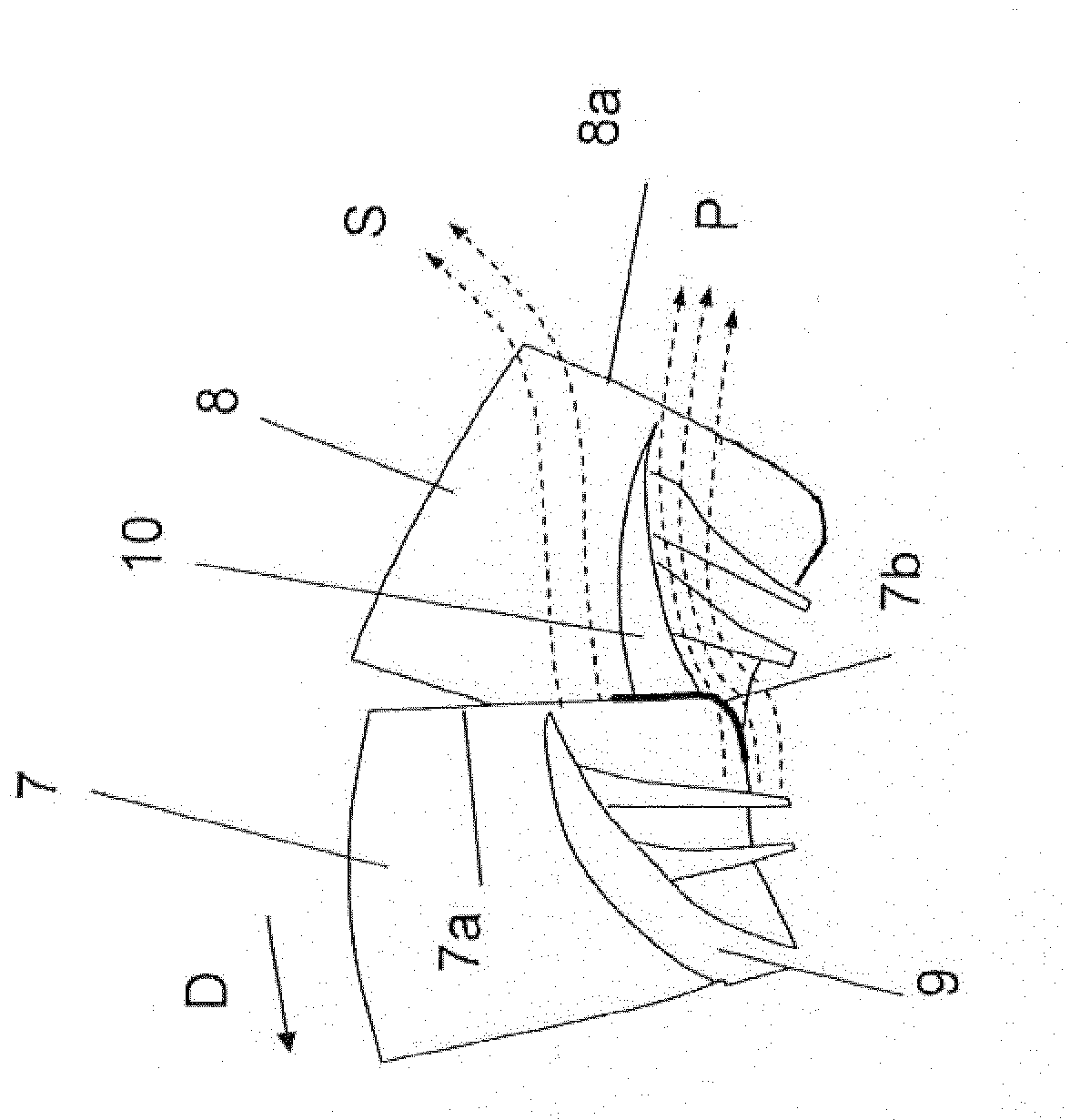

[0028] figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com