Battery system for measuring battery module voltages

A battery system and battery technology, applied in the field of battery systems, can solve problems such as battery system failure, and achieve the effect of avoiding subsequent losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

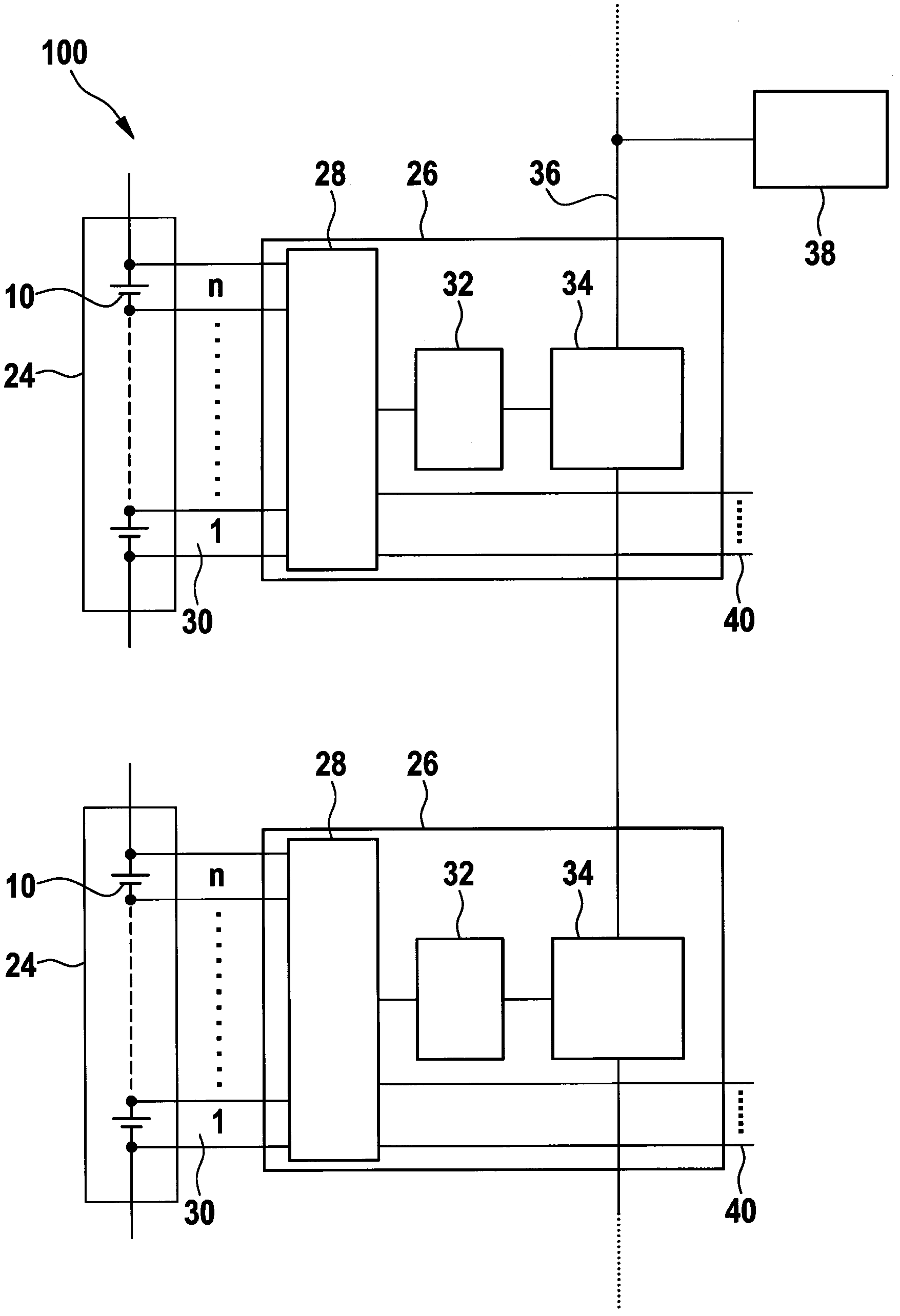

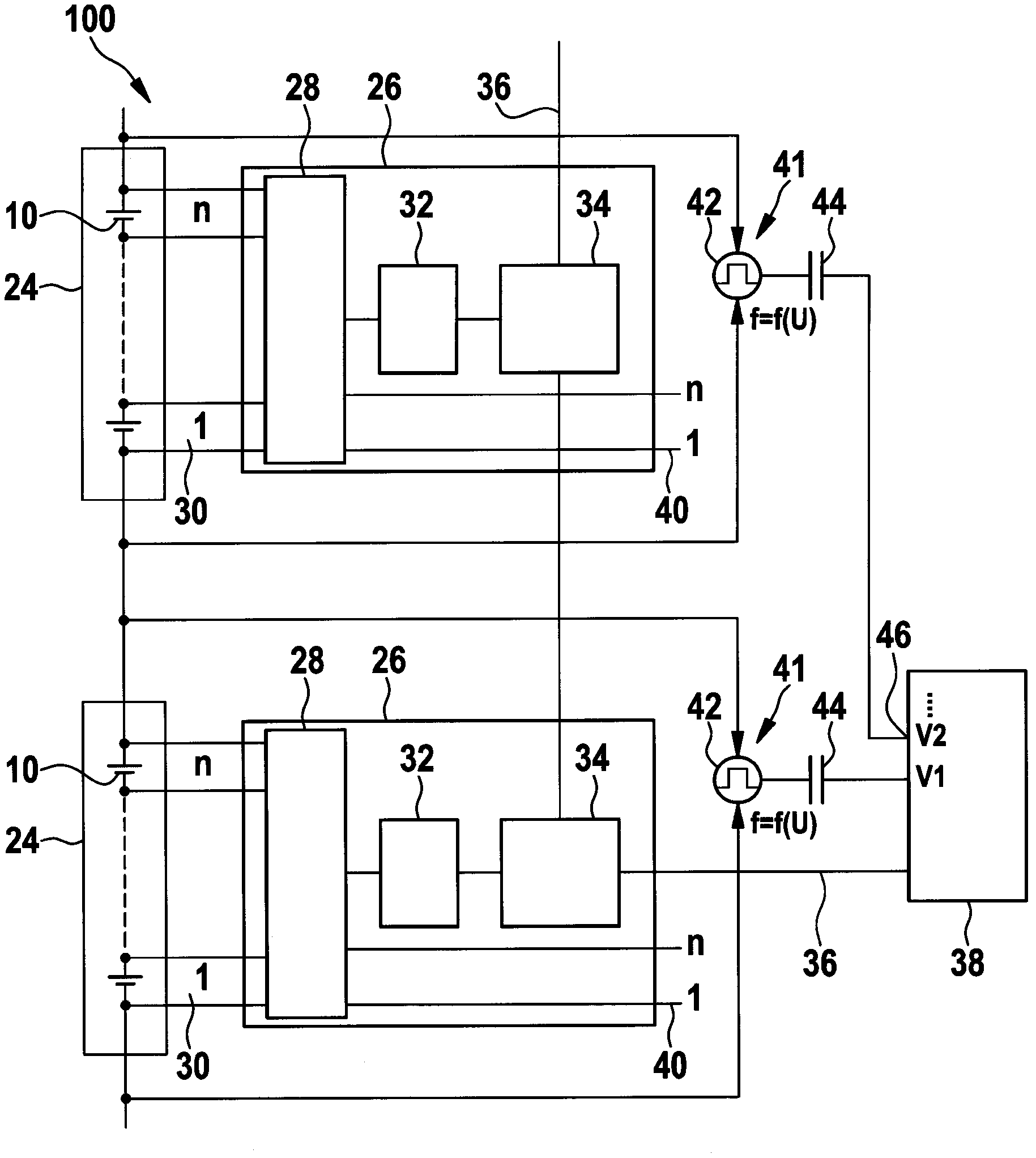

[0022] image 3 A battery system 100 according to the invention is shown. A plurality of battery cells 10 are connected in series and integrated in a module 24 . In multiplexer 28 , the cell voltages of the individual battery cells 10 are combined and fed into communication bus 36 via analog-to-digital converter 32 and gateway 34 . The voltage evaluation is carried out by the microcontroller 38 in a known manner.

[0023] exist image 3 Two modules 24 each having a plurality of battery cells 10 are shown by way of example. According to further, not shown embodiments, further modules 24 can also be connected in series or in parallel with each other.

[0024] Each module 24 is associated with a module voltage acquisition unit 41 . The module voltage acquisition unit 41 taps in the voltage applied to the module 24 and feeds this voltage into an oscillator 42 . Oscillators 42 are each coupled via a capacitor circuit 44 to an input 46 of evaluation circuit 38 .

[0025] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com