Method for preventing heavy metal in sludge matrix from being leaked by adoption of interlayer of fly ash and biochar

A technology of biochar and fly ash, which is applied in botany equipment and methods, sludge treatment, chemical instruments and methods, etc., and can solve the problems of difficulty in preparation and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

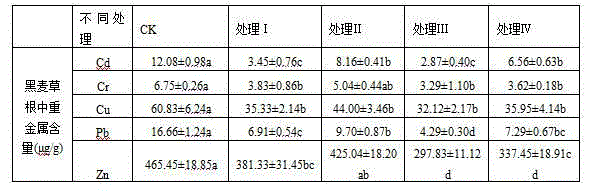

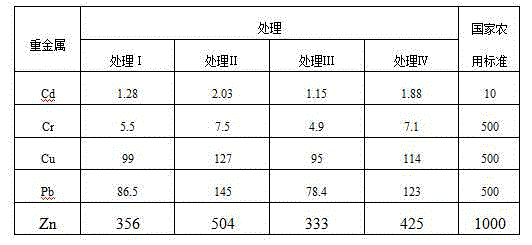

Examples

Embodiment 1

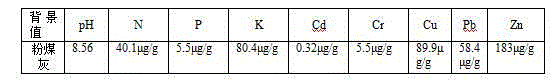

[0065] Composition of fly ash and biochar interlayer to prevent heavy metal leakage from sludge matrix: 40 sludge; 10 biochar; 50 fly ash.

[0066] The method of using fly ash and biochar interlayer to prevent the leakage of heavy metals in sludge matrix:

[0067] (1) First mix the sludge, biochar, and fly ash according to the above weight ratio and stir evenly, then, the mixed matrix is evenly put into PVC pipes, each pipe is 24 cm high and 7.5 cm in diameter, and each PVC pipe is loaded into The total amount of matrix is 850 g, the upper 8 cm is 350 g of mixed matrix of sludge biochar and fly ash, and the lower 16 cm is 500 g of garden soil;

[0068] (2) Plant 0.6 g of ryegrass seeds per PVC, soak Cui buds before planting the seeds, and regularly water the same amount during the planting period to keep the overall field water holding capacity at 60%. The indoor temperature and relative humidity during the planting period were respectively at 25°C and 36-%, the light int...

Embodiment 2

[0073] A fly ash and biochar interlayer for preventing heavy metal leakage from the sludge matrix is characterized in that it is composed of the following raw materials by weight fraction:

[0074] 40 sludge; 10 biochar; 50 fly ash.

[0075] The method of using fly ash and biochar interlayer to prevent the leakage of heavy metals in sludge matrix:

[0076] (1) First mix the sludge, biochar, and fly ash according to the above weight ratio and stir evenly, then, the mixed matrix is evenly put into PVC pipes, each pipe is 24 cm high and 7.5 cm in diameter, and each PVC pipe is loaded into The total amount of matrix is 850 g, the upper 8 cm is 350 g of mixed matrix of sludge biochar and fly ash, and the lower 16 cm is 500 g of garden soil;

[0077] (2) Plant 0.6 g of ryegrass seeds per PVC, soak Cui buds before planting the seeds, and regularly water the same amount during the planting period to keep the overall field water holding capacity at 60%. The indoor temperature an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com