Clamping device of clamp body of long-tail clamp automatic assembling machine

A technology of clamping device and long tail clamp, which is applied in the direction of workpiece clamping device, metal processing, metal processing equipment, etc., can solve the problems of slow assembly speed and inaccurate clamp body positioning, and achieve high clamping efficiency and replaceable Good performance, improve the effect of automatic positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

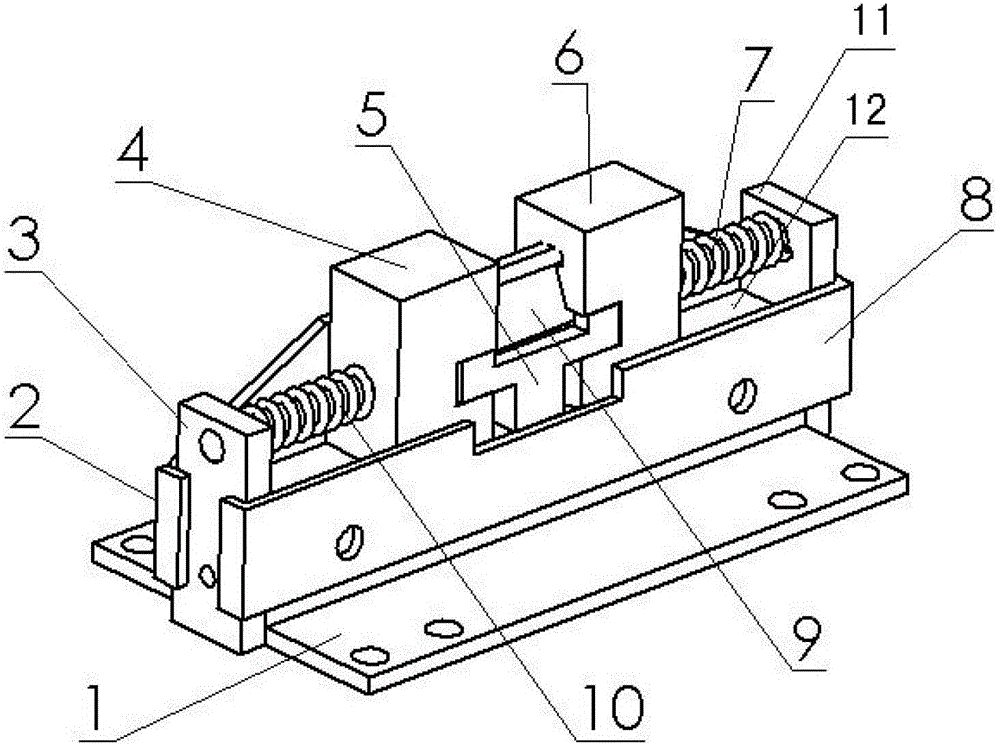

[0017] refer to Figure 1 to Figure 4 , the clip body clamping device of the long tail clip automatic assembly machine, including a clamping mechanism and a push-off mechanism;

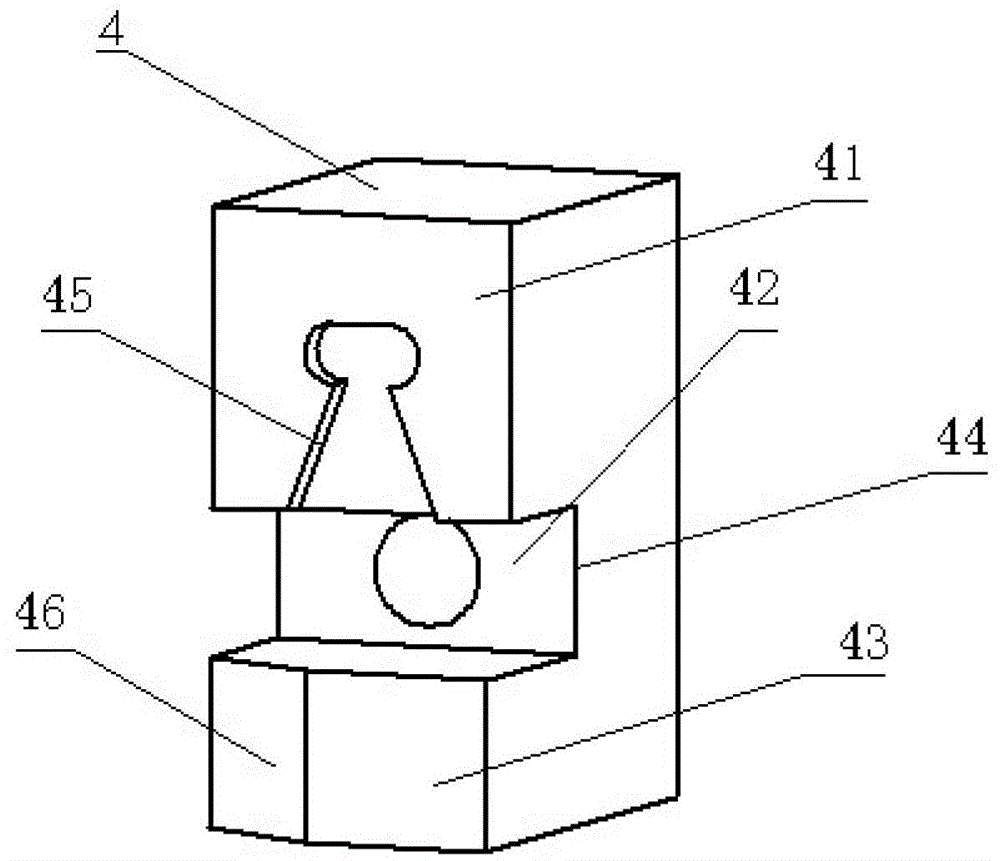

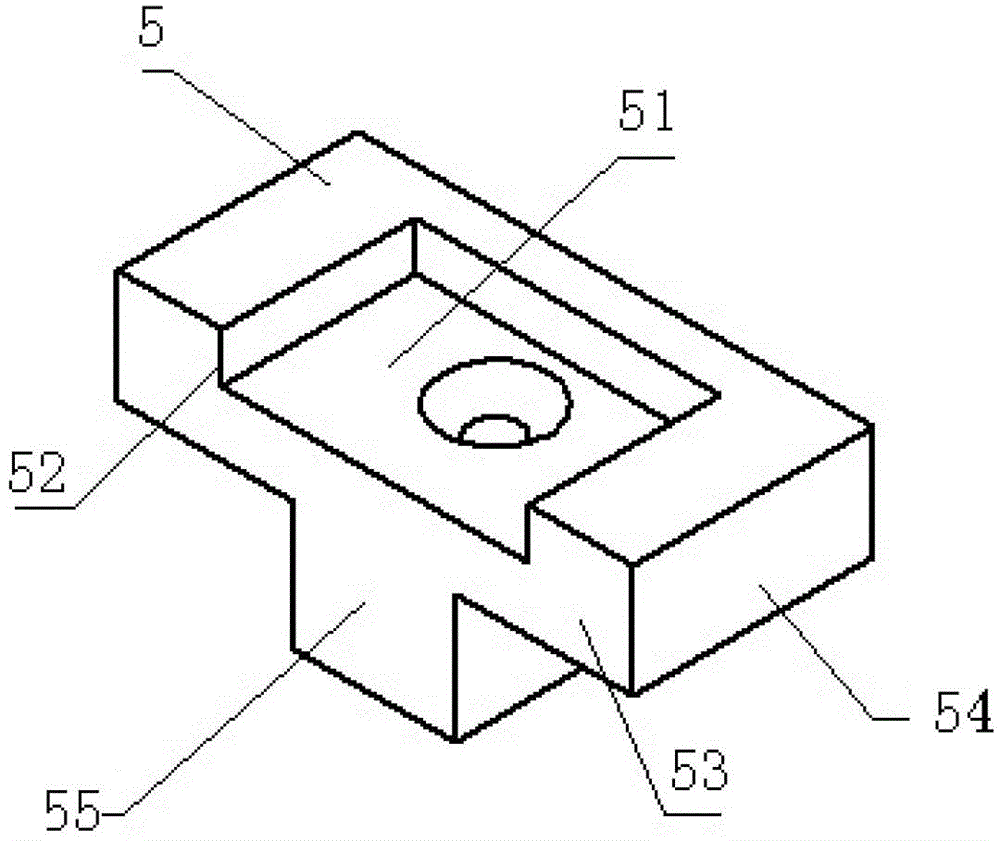

[0018] The clamping mechanism includes a convex base 1, on which the left and right baffles 2, 8 and front and rear stoppers 3, 11 are fixed, and the left and right baffles 2, 8 and front and rear block 3,11 cooperate mutually to form slideway 12, and described front and rear block 3,11 are connected with a spring guide bar 7; The center of described slideway 12 is provided with clip body base 5, and described The upper surface of the clip body base 5 is provided with a bottom positioning groove 51 for placing the long tail clip clip body 9, and the left and right sides of the clip body base 5 are respectively provided with a left slider 4 and a right slider 6. The upper right end face 41 of the slide block 4 and the upper left end face of the right slide block are all provided with the side position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com