Automatic gluing device for surface of plastic part and using method of automatic gluing device

A gluing device and a technology for plastic parts, which are applied in the direction of electrostatic cleaning, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of foreign matter affecting the gluing effect, insufficient gluing, and low efficiency, and achieve saving Remove the glue, deal with it fully, and ensure the effect of vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

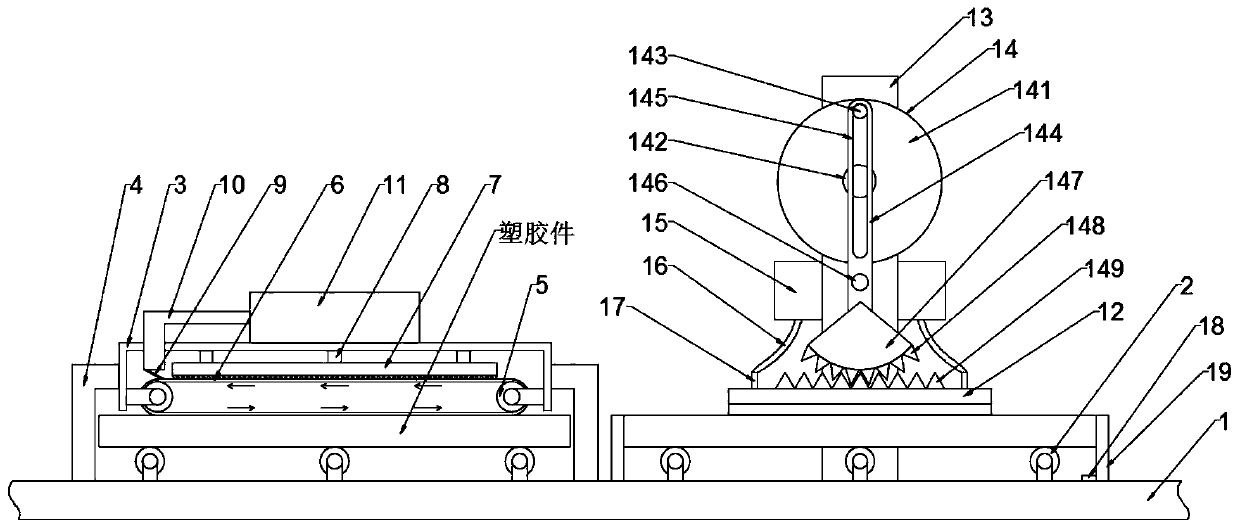

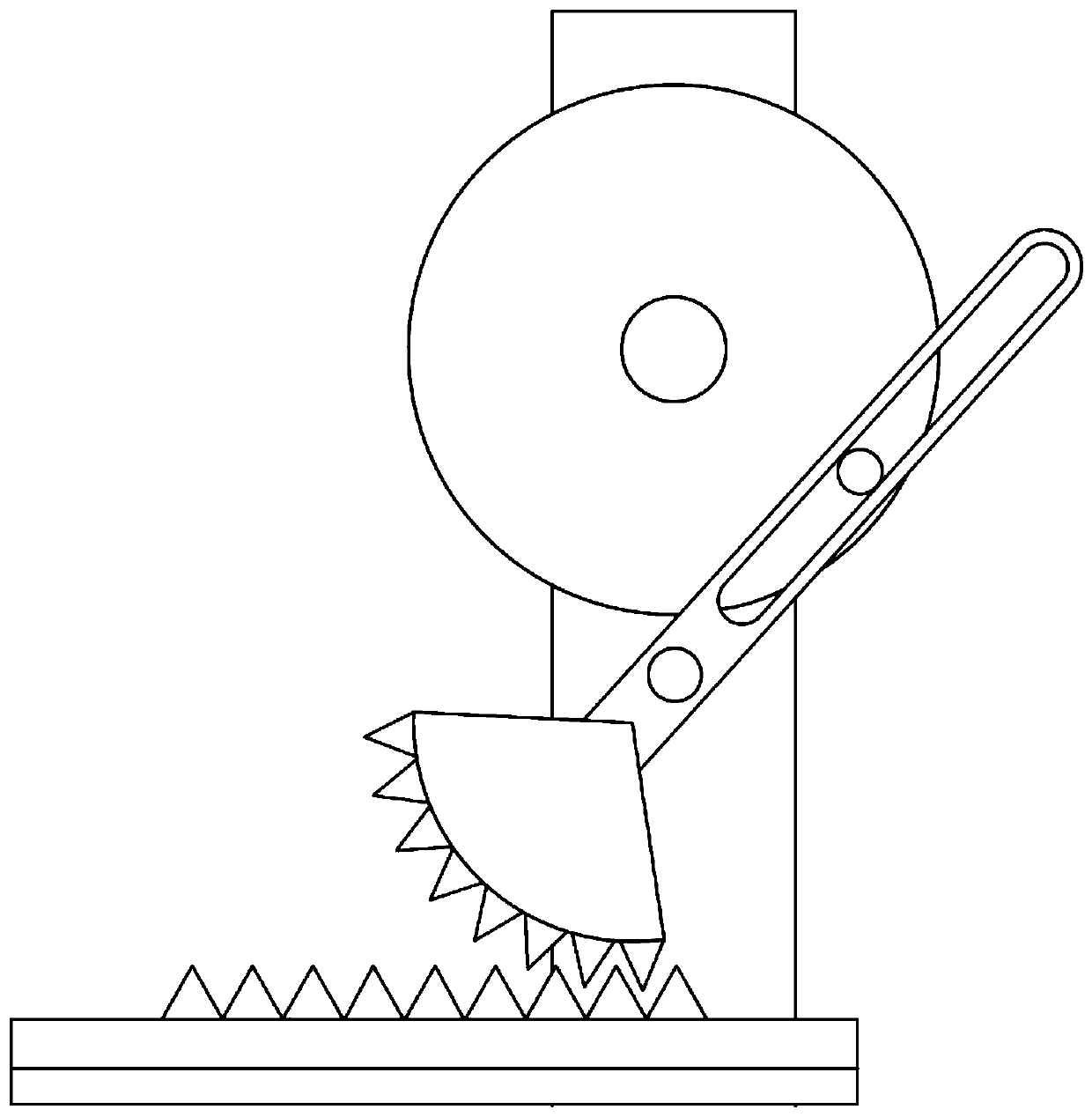

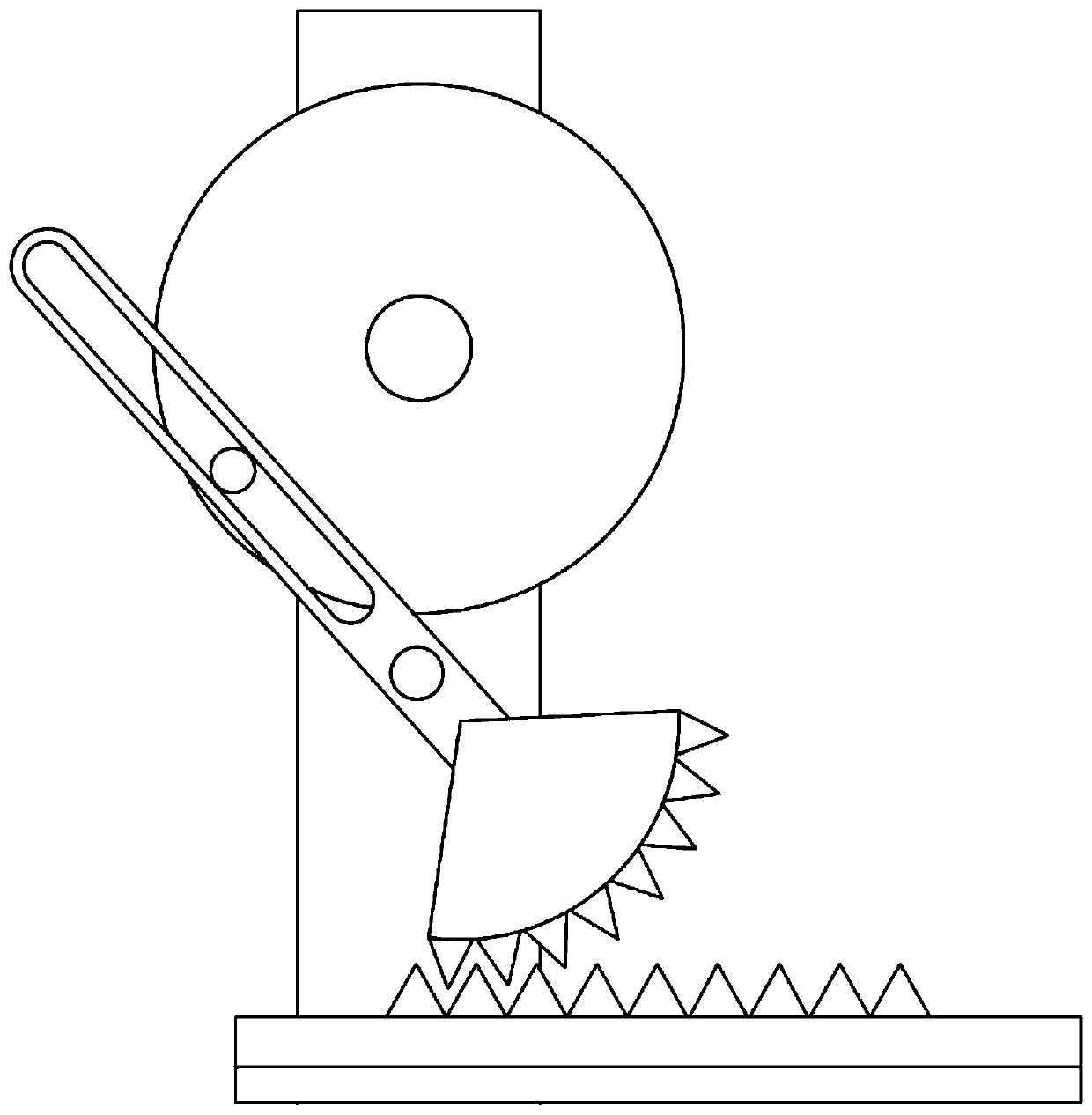

[0045] see figure 1 , an automatic gluing device for the surface of plastic parts, comprising a workbench (1), the upper surface of the workbench (1) is uniformly provided with a plurality of conveying rollers (2), and the plurality of conveying rollers (2) are driven by a pulley drive mechanism To achieve synchronous rotation, plastic parts are supported on the conveying roller (2), and an electrostatic dust removal device and a swing glue brushing device are arranged on the left and right above the workbench (1);

[0046] The electrostatic precipitator comprises a dust removal frame (3). Support rods (4) are connected to both sides of the dust removal frame (3). The support rods (4) are fixed on the upper surface of the workbench (1). A rotating roller group (5) is arranged on the side wall, and an electrostatic adsorption belt (6) is sleeved on the rotating roller group (5). The upper side of the electrostatic adsorption belt (6) is provided with an electrostatic friction l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com