Electromagnetic braking system

A technology of electromagnetic brake and brake clutch, which is applied in the fields of electric brake system, electric vehicle, transportation and packaging, etc. It can solve the problem of difficulty in maintaining the linearity of vehicle braking force, overheating of brake pads and brake discs, and driver discomfort Braking feeling and other problems, to avoid the decline of braking performance, to avoid the wear and tear of parts and to improve the effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

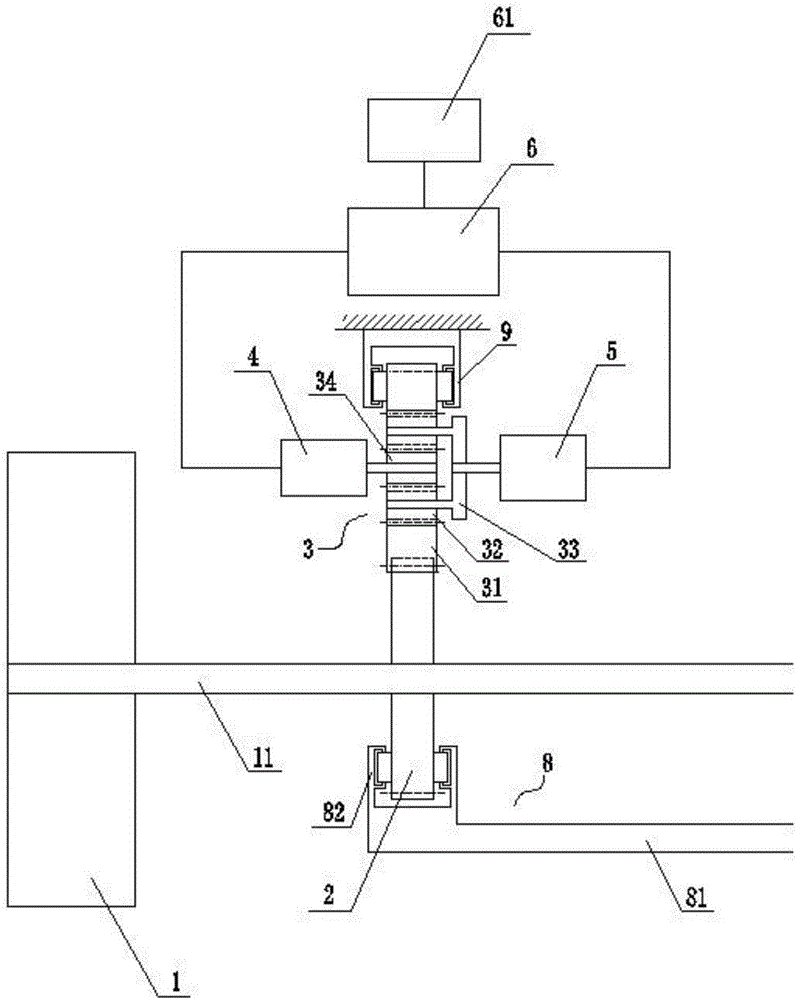

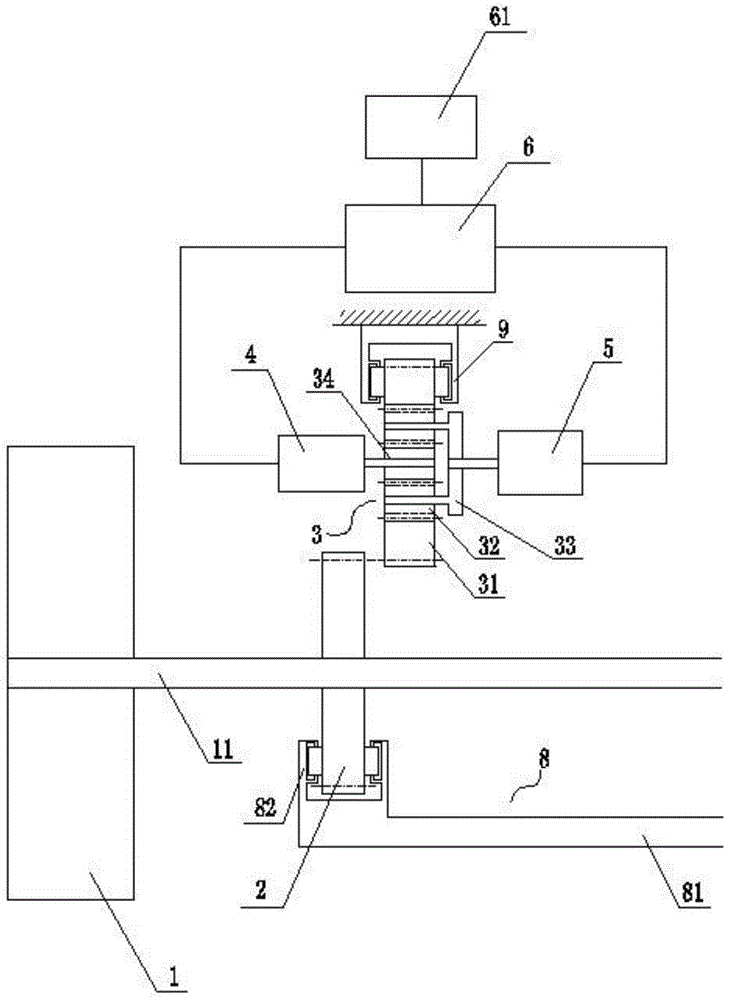

[0026] refer to figure 1 and figure 2 . An electromagnetic braking system is composed of a reduction gear 2, a planetary gear train 3, a generator 4, a motor 5, a controller 6, a brake clutch 8 and a battery pack 61, and the reduction gear 2 is connected to a wheel 1 through an axle 11. Connected, the reduction gear 2 rotates under the drive of the wheel.

[0027] The brake clutch 8 can push the reduction gear 2 to move along the axial direction of the axle 11 . The brake clutch 8 includes a push rod 81 and a first roller limiting device 82, the rollers of the first roller limiting device 82 are in contact with the side of the reduction gear 2 and can move along the reduction gear. 2 side scrolling. The push rod 81 provides a thrust for pushing the reduction gear 2 to move along the axial direction of the axle 11, and the first roller limiting device 82 plays the role of transmitting the thrust to the reduction gear 2 and limiting .

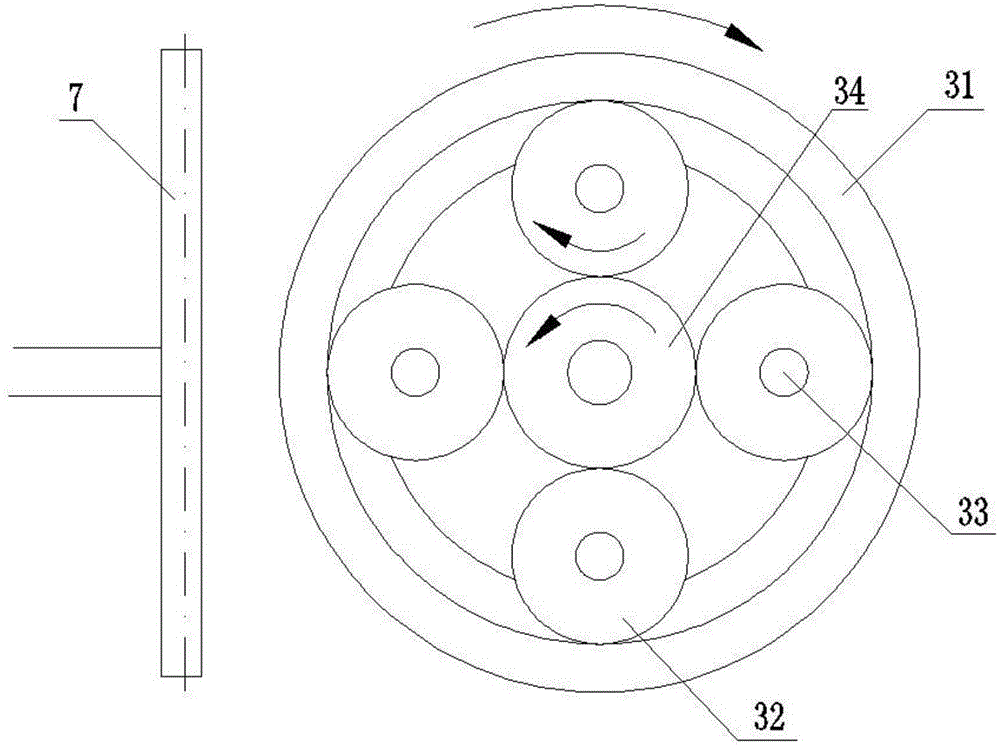

[0028] The planetary gear train 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com