Multi-workstation high-speed cover distributing device

A multi-station, cover-separating technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of unstable discharge and material jam, and achieve the effect of accurate cover separation, stable transmission and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

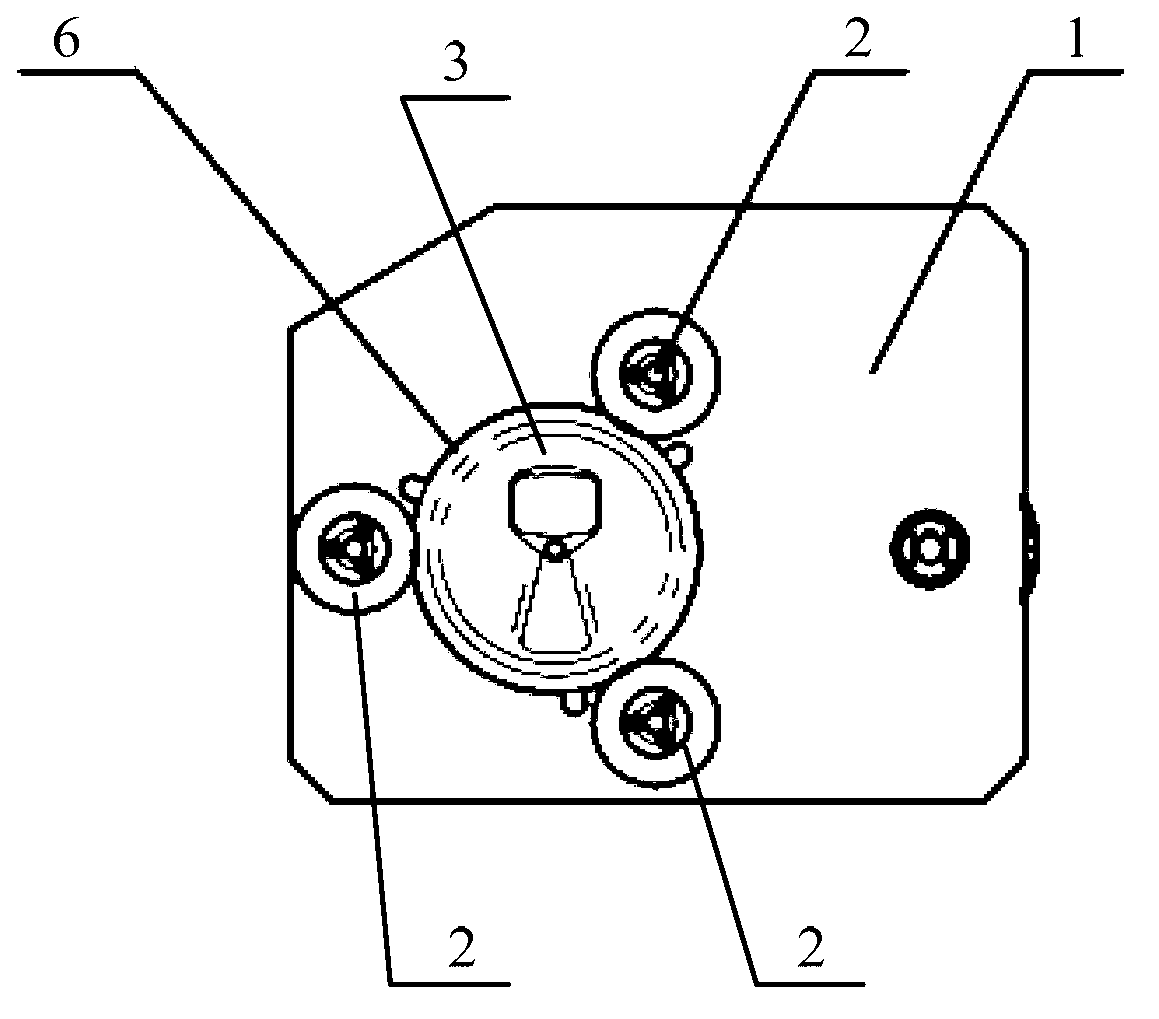

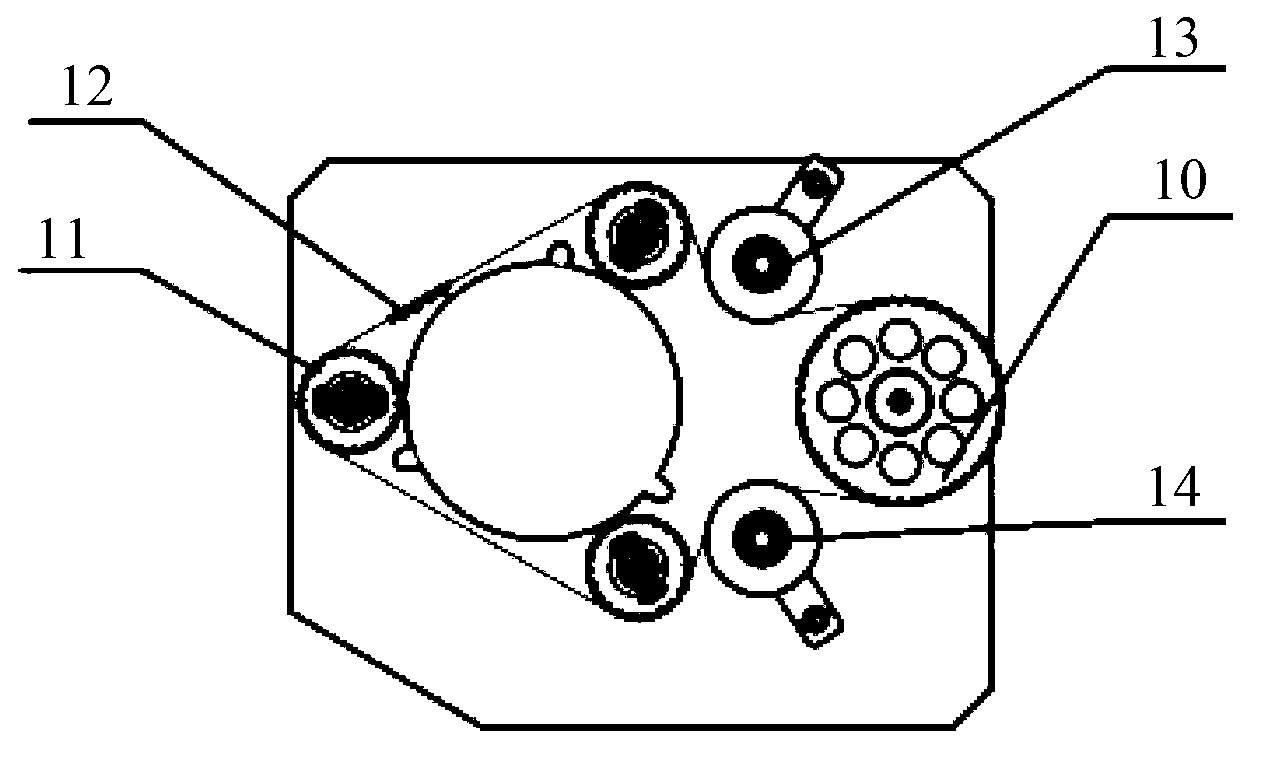

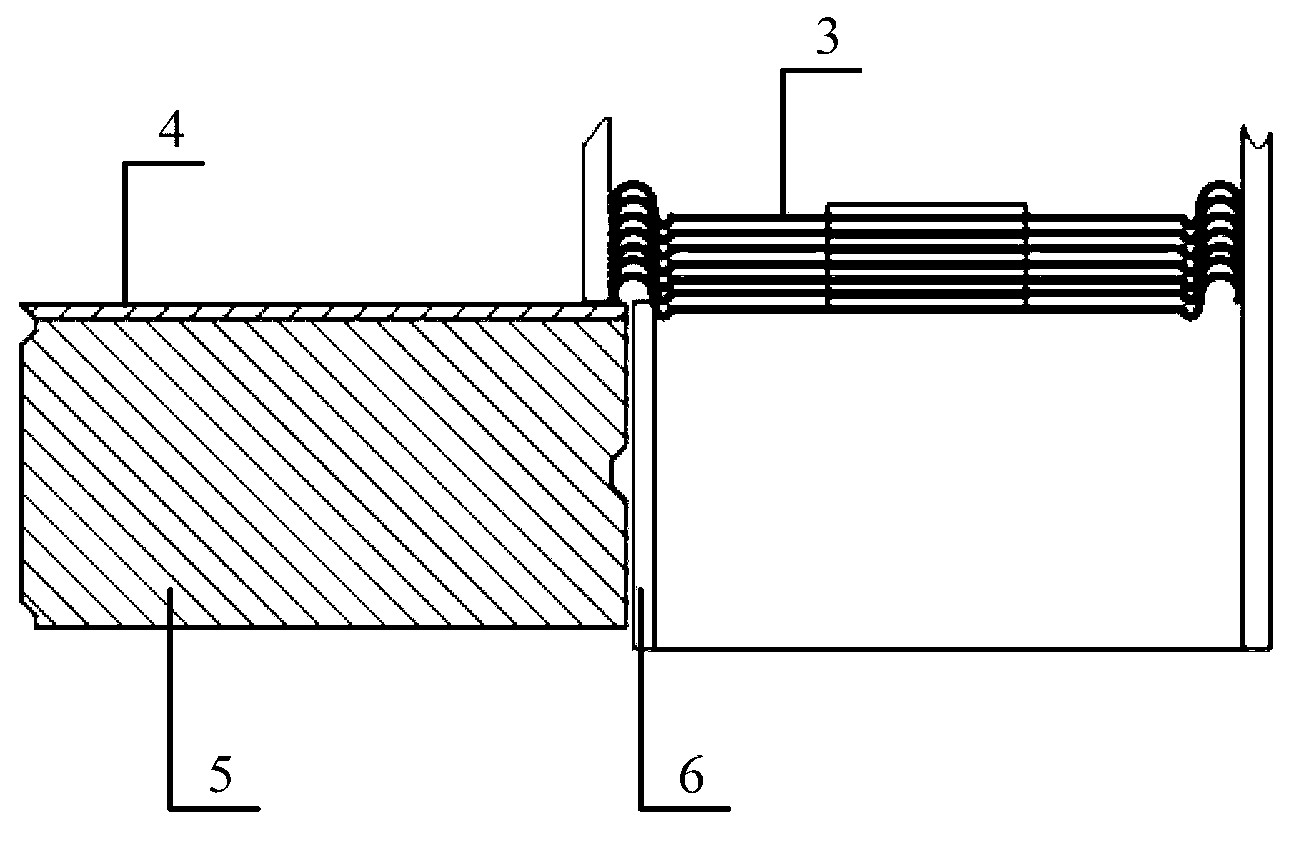

[0034] Such as Figure 1 to Figure 6 As shown, the present invention provides a multi-station high-speed cap-separating device, which is composed of a worktable 1, a cylinder body 6, a plurality of cap-separating mechanisms 2 and a transmission mechanism. In this embodiment, there are three cap-separating mechanisms, and the three cap-separating mechanisms are evenly distributed on the outer edge of the cylinder 6 and rotate synchronously around the cylinder 6 in the same direction and speed. This embodiment uses the principle of three points to determine a plane, and the accuracy and stability of the lid-splitting operation can be made through the three lid-splitting mechanisms. Horizontal position to overcome the problem that the existing one or two lid separating mechanisms easily cause the position of the can lid to be tilted and the discharge is unstable when the can lid is divided.

[0035] The sub-cap mechanism 2 is composed of a sub-cap knife seat 5 and a sub-cap knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com