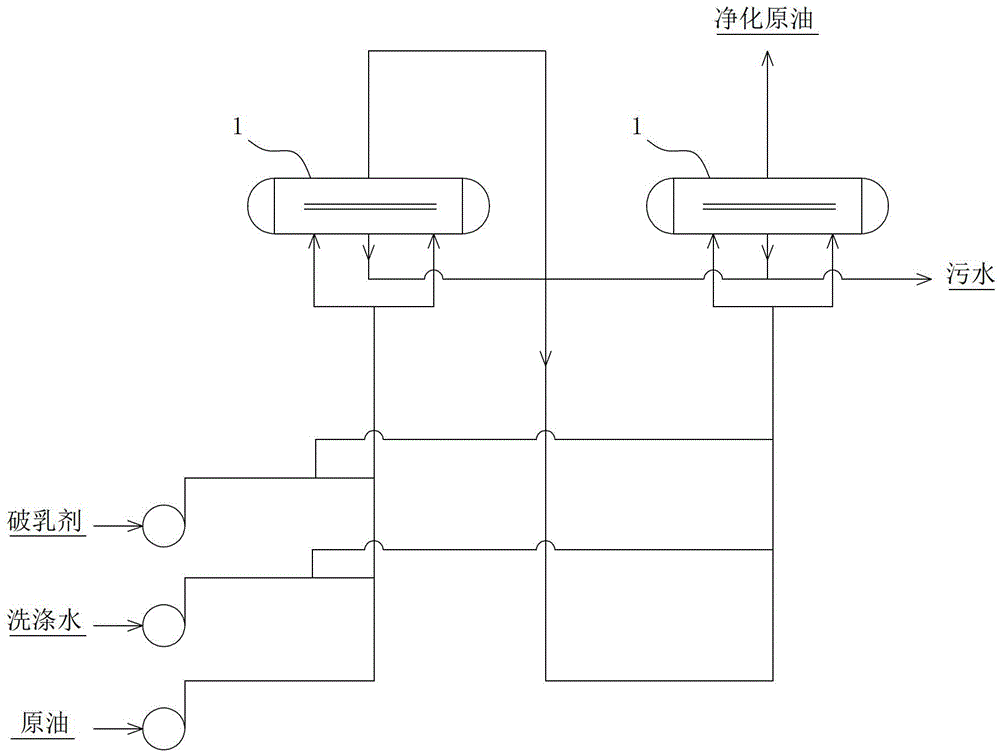

Crude oil electric desalting method and electric desalting device

A technology of electric desalination and crude oil, applied in the field of electric desalination of crude oil, can solve the problems of large sewage, large washing water, inconvenient follow-up treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

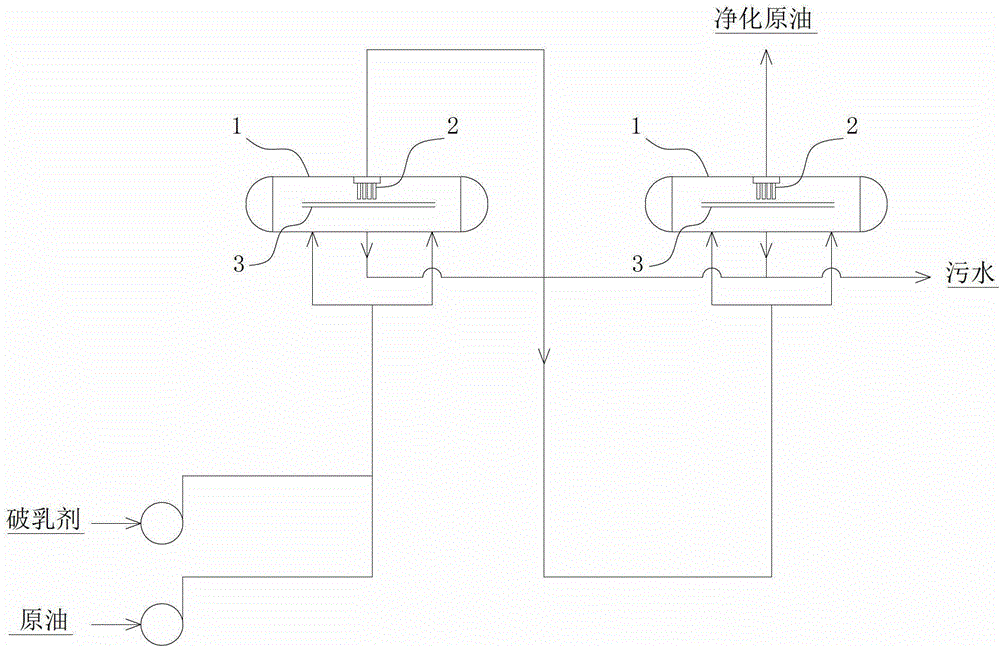

[0011] Such as figure 2 As shown, the secondary electric desalting method of crude oil is as follows: a) The first stage electric desalting: under the condition of not adding washing water, the crude oil to be desalted is mixed with the demulsifier, and then injected into the electric desalting tank 1 at a suitable temperature, Furthermore, the separation of oil and water is realized in the electric desalting tank, and the separated oil passes through the filter 2 located in the electric desalting tank 1 to filter out the solid salts therein and then becomes the first-stage purified crude oil, and the separated water is purified in the electric desalting tank 1 After settling in tank 1, it is discharged; b) second-stage electric desalting: without adding washing water and demulsifier, inject the first-stage purified crude oil into electric desalting tank 1 at a suitable temperature, and then in the electric desalting tank To achieve oil-water separation, the separated oil pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com