High-strength cast aluminum-silicon alloy material and application thereof to hydraulic shell

A technology of casting aluminum-silicon alloy and hydraulic housing, which is applied to casting aluminum alloy materials and its application fields in automobiles, aviation and aerospace, and can solve the problems that A356 materials cannot meet the technical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2)

[0037] The hydraulic casing made of this high-strength cast aluminum-silicon alloy (as in Example 2) must be tested in the following aspects:

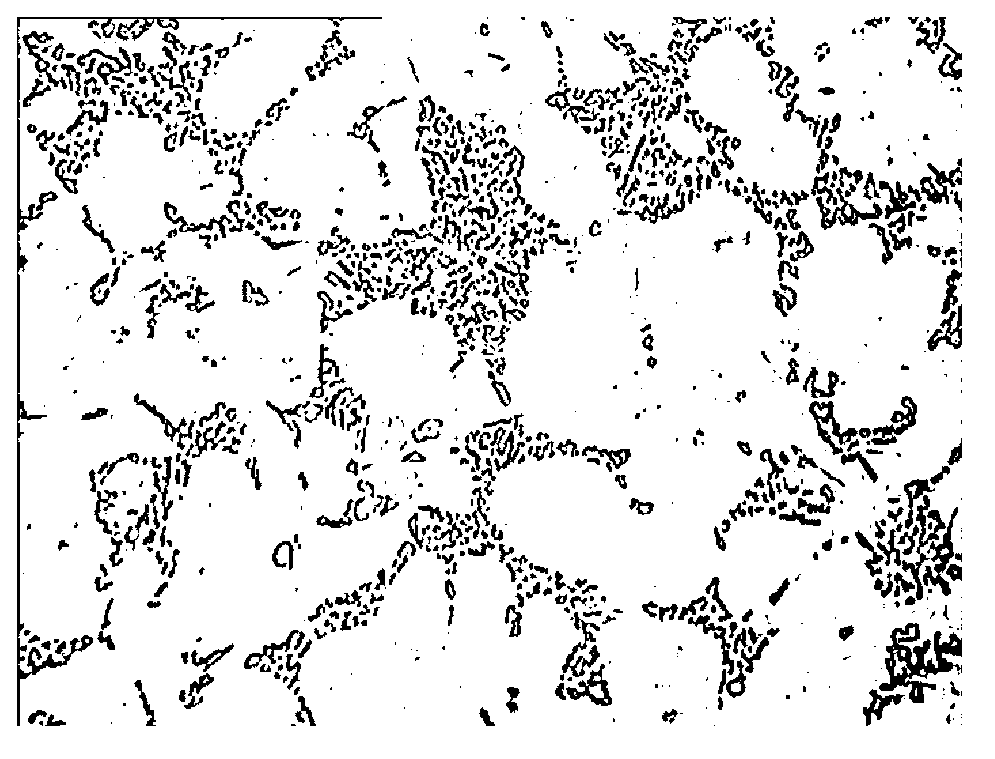

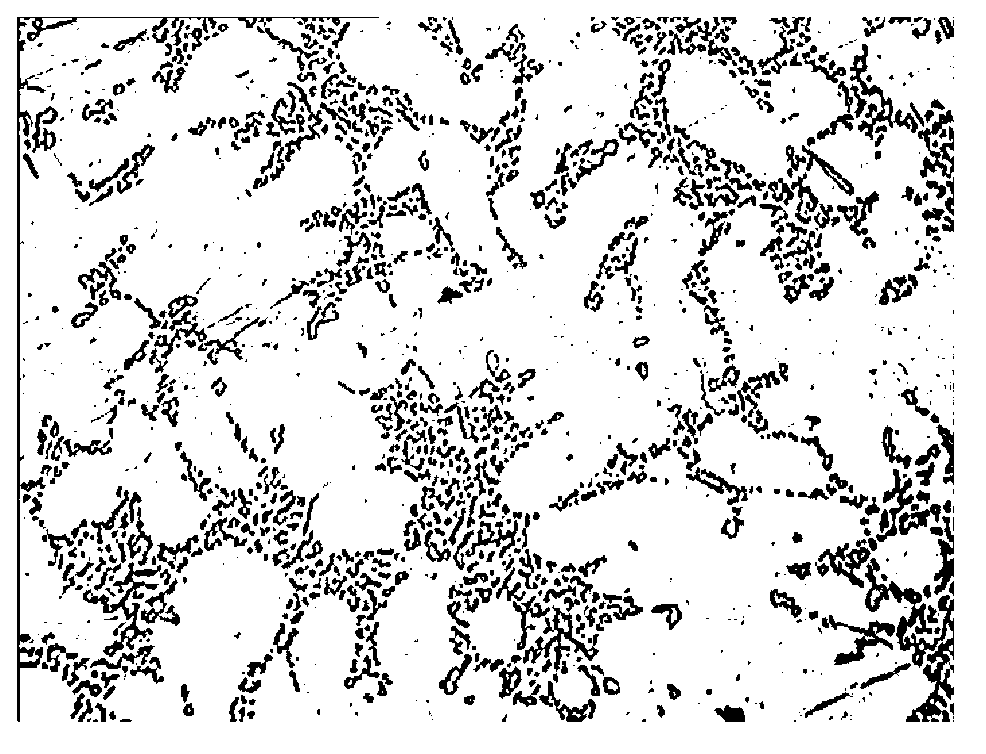

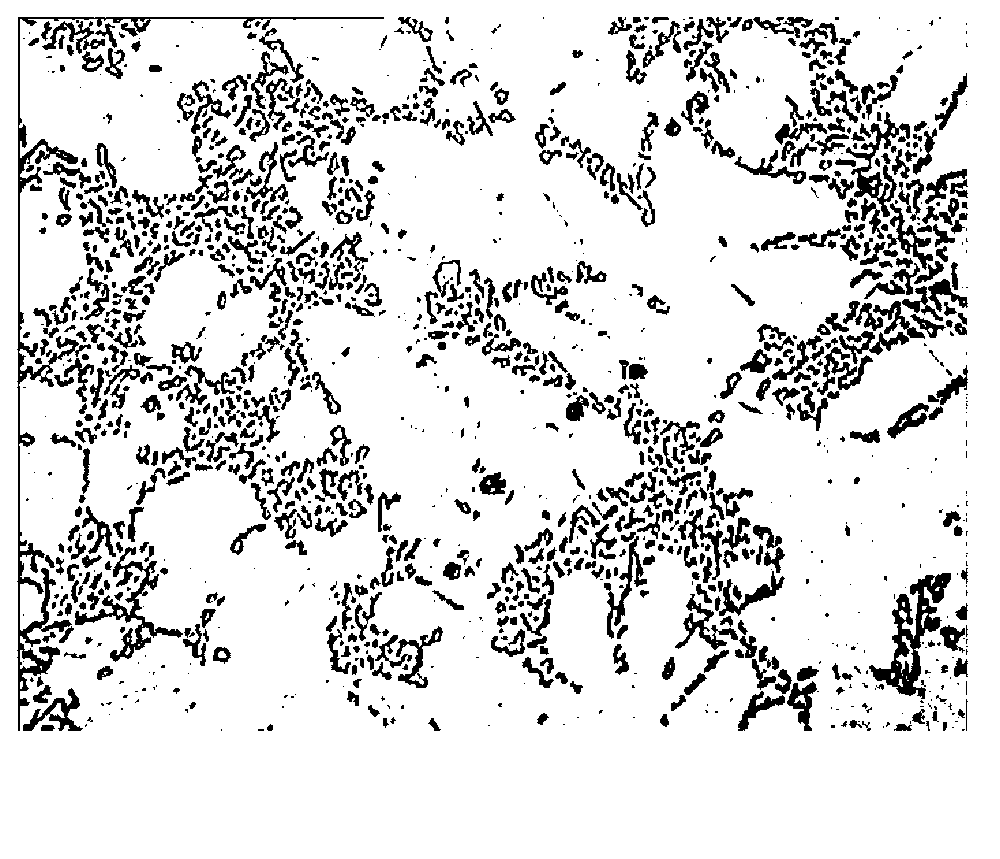

[0038] 1. Metallographic structure ( Figure 1-3 )

[0039] From the microstructure point of view, no overburned triangles or grain boundary melting, remelted balls, and remelted eutectic structures were found, indicating that the organization was normal, and no overheated or overheated structures were found. From the perspective of thick wall and thin wall metallographic structure, the eutectic silicon is small, the corners of eutectic silicon are smooth, distributed along the dendrite network, the organization is evenly distributed, and the dendrite network is basically evenly distributed.

[0040] 2. Performance test

[0041] 2.1 Tensile and hardness tests at room temperature

[0042] The product was sampled for testing, and the test results are shown in the table below:

[0043]

[0044] 2.2 High temperature tensile test

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com