Construction method for assembling steel truss barrel-shell-structured dry coal shed

A construction method and steel grid technology, applied in building structure, construction material processing, construction, etc., can solve problems such as large scaffolding and slow progress, and achieve the effects of improving production efficiency, reducing construction costs, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

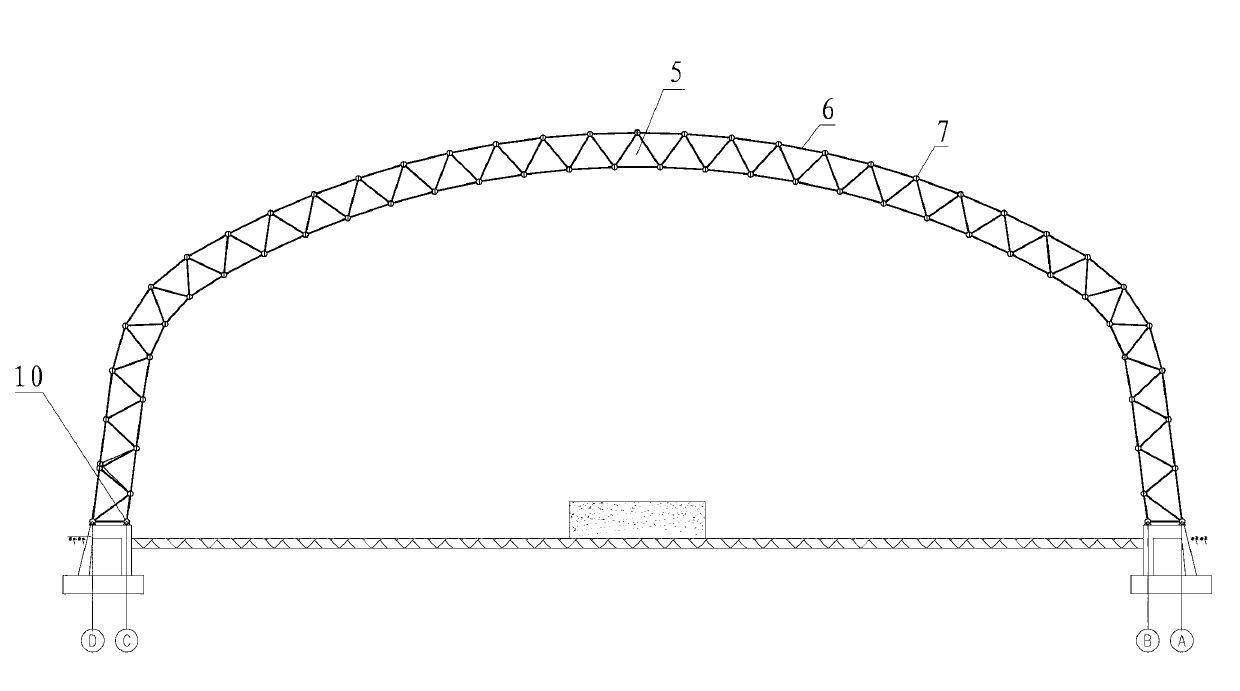

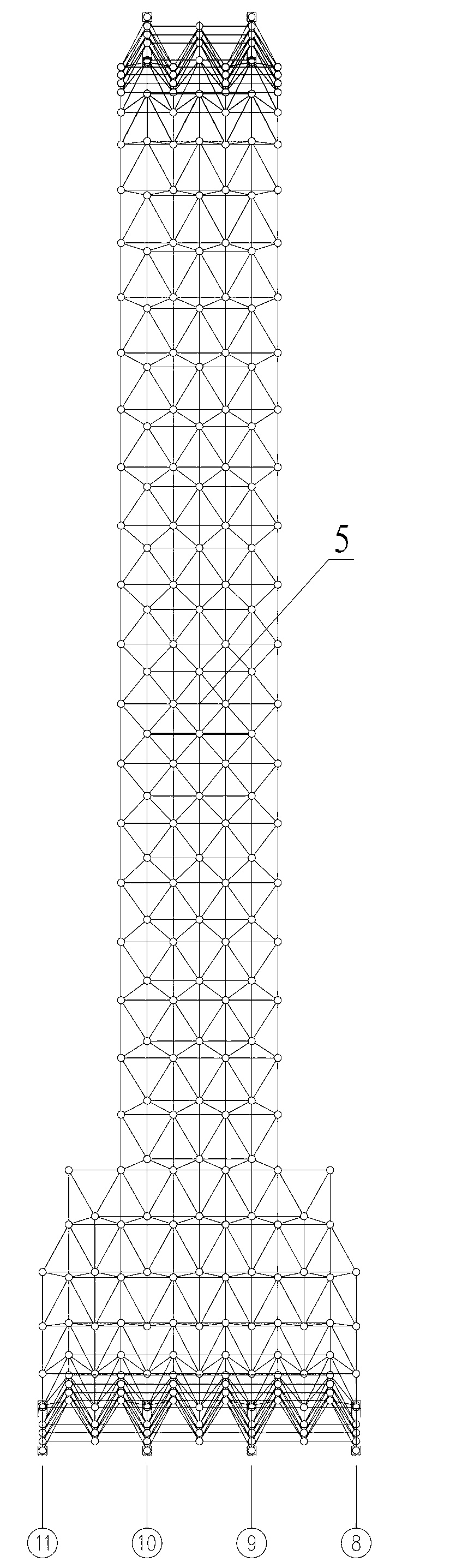

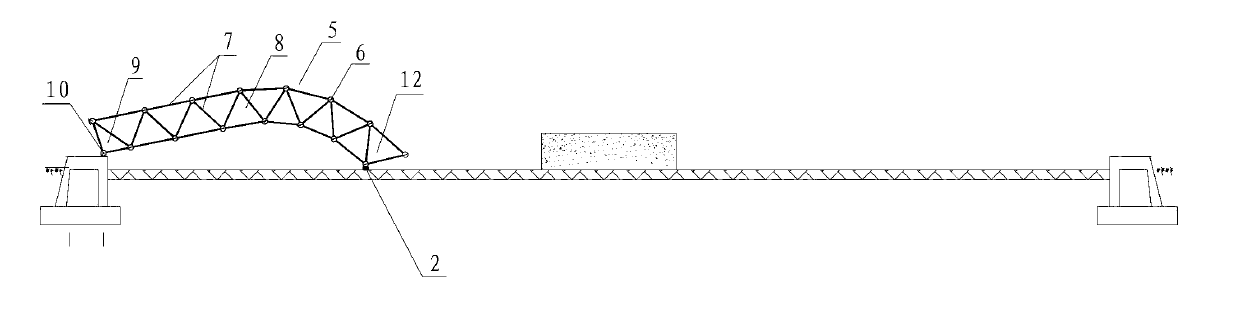

[0029] like Figure 1 to Figure 7 Shown is a construction method provided by the present invention for assembling dry coal sheds with a steel grid shell structure that is low in construction cost, fast in construction progress, and can effectively ensure the personal safety of construction personnel. The construction method includes the following steps,

[0030] 1) Determine the lifting point 1, the support point 2 and the span control pull joint 3 and prepare the parts for making the trihedral quadrangular small cone 4,

[0031] First, according to the structural characteristics of the dry coal shed with steel grid shell structure, determine the large structural unit 5 with at least two longitudinal span axes in the middle as a whole; then determine and assemble the large structural unit 5 on the large structural unit 5 according to the calculation Lifting and supporting the lifting point 1 and the supporting point 2 positions of the large structural unit when the structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com