Testing method for effective pore volume and porosity of lithium ion battery pole piece

A test method, pore volume technology, applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as expensive equipment, threats to human health, operators and environmental hazards, and achieve easy The production and test methods are simple and reliable, and the effect is easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

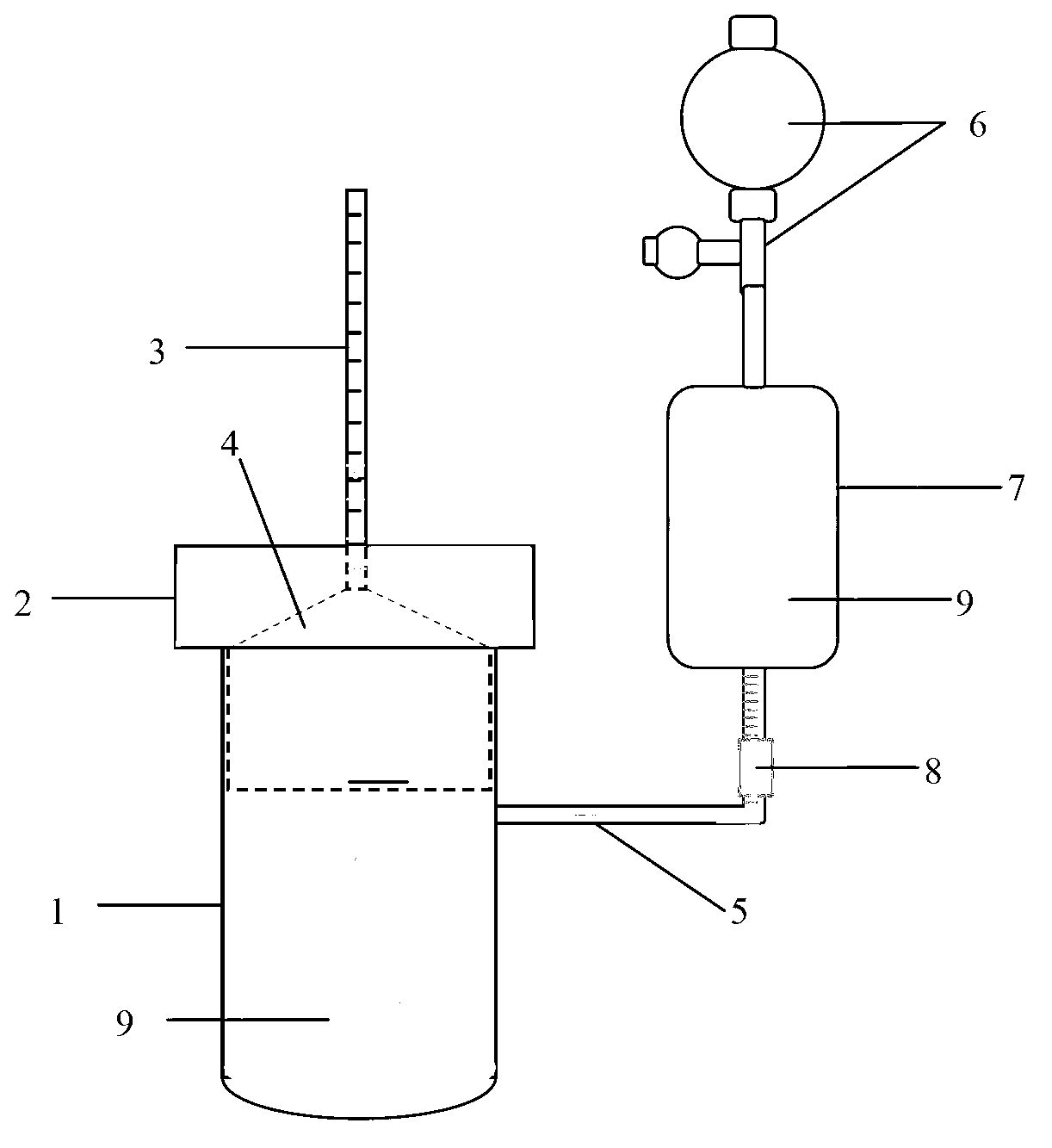

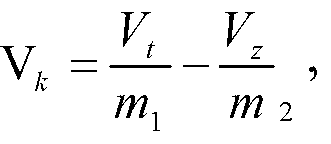

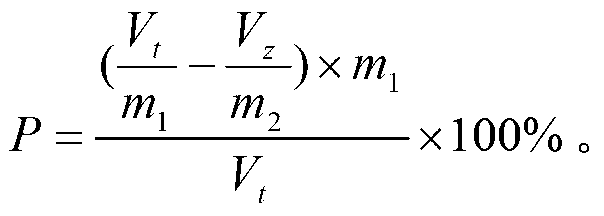

Method used

Image

Examples

Embodiment 1

[0018] In this example, the effective pore volume and porosity of lithium-ion battery cathode sheets with different compacted thicknesses were tested, and compared with the mercury porosimetry test data. The mercury porosimeter used was Autopore Ⅳ 9500 from American Mike Company, and the digitally controlled ultrasonic cleaner was KQ2200DE from Kunshan Ultrasonic Instrument Co., Ltd.

[0019] Take the positive electrode sheet of the lithium-ion battery to be tested, the compacted thicknesses are respectively: 98 μm and 102 μm, and dry them in a vacuum oven. First take a sample of 98 μm for testing: cut two samples with a length of 16 cm from the pole piece, and the width is the original width of the pole piece, which are recorded as S1 and S2 respectively, wipe the surface with a soft cloth, and weigh the mass with an analytical balance Recorded as m1 and m2, recorded in Table 1.

[0020] Table 1 Test results of effective pore volume and porosity of pole pieces

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com