Fiber Bragg Grating Seismic Acceleration Detector Based on Combined Cantilever Beam Structure

A seismic acceleration and fiber grating technology, applied in the direction of seismic signal receivers, etc., can solve the problems of large dynamic range and can not meet the sensitivity at the same time, and achieve the effect of large dynamic range, high sensitivity and wide response frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

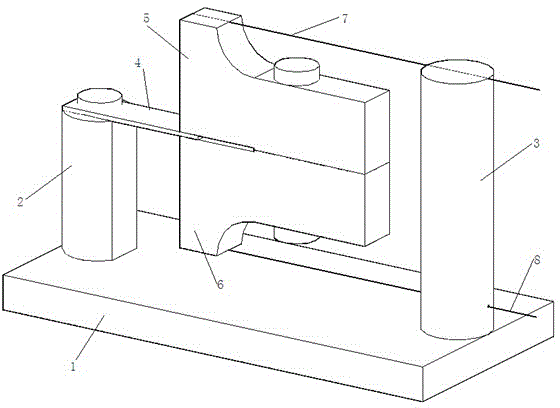

[0012] Below in conjunction with accompanying drawing, content of the invention will be further described:

[0013] refer to figure 1 As shown, the fiber grating seismic acceleration detector based on the combined cantilever beam structure includes a plate base 1, and the top of the base 1 is provided with a columnar support column 2 and a columnar connector 3, and the connector 3 is processed with a through hole. The top of the column 2 is fixed to one end of the cantilever beam 4 with the same cross-section, and the other end of the cantilever beam 4 with the same cross-section is connected to the mass block. The L-shaped cantilever beam 5 and the second right-angle folding ruler L-shaped cantilever beam 6 are combined. An outer wall of the ruler L-shaped cantilever beam 6 is overlapped and combined in a mirror image from top to bottom, the upper end of the mass block and the upper end of the connecting piece 3 are on the same level, and the lower end of the mass block is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com