Product modeling method based on interactive feature pair

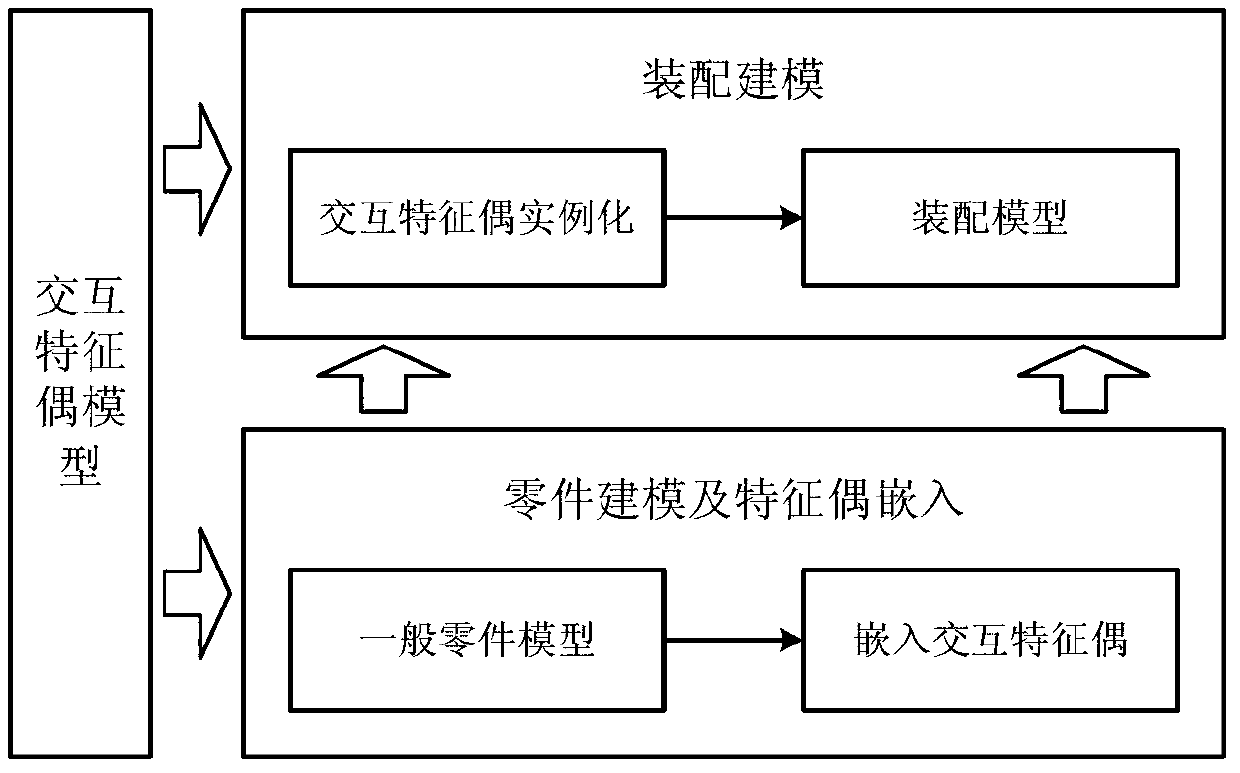

A product modeling and product technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as dependence, difficulty in consistency, and difficulty in generating general methods to ensure consistency and good products. Assembly Modeling Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This implementation example is to build an assembly model platform-top cone 9 of platform 1 and top cone 2 based on the interactive feature pair.

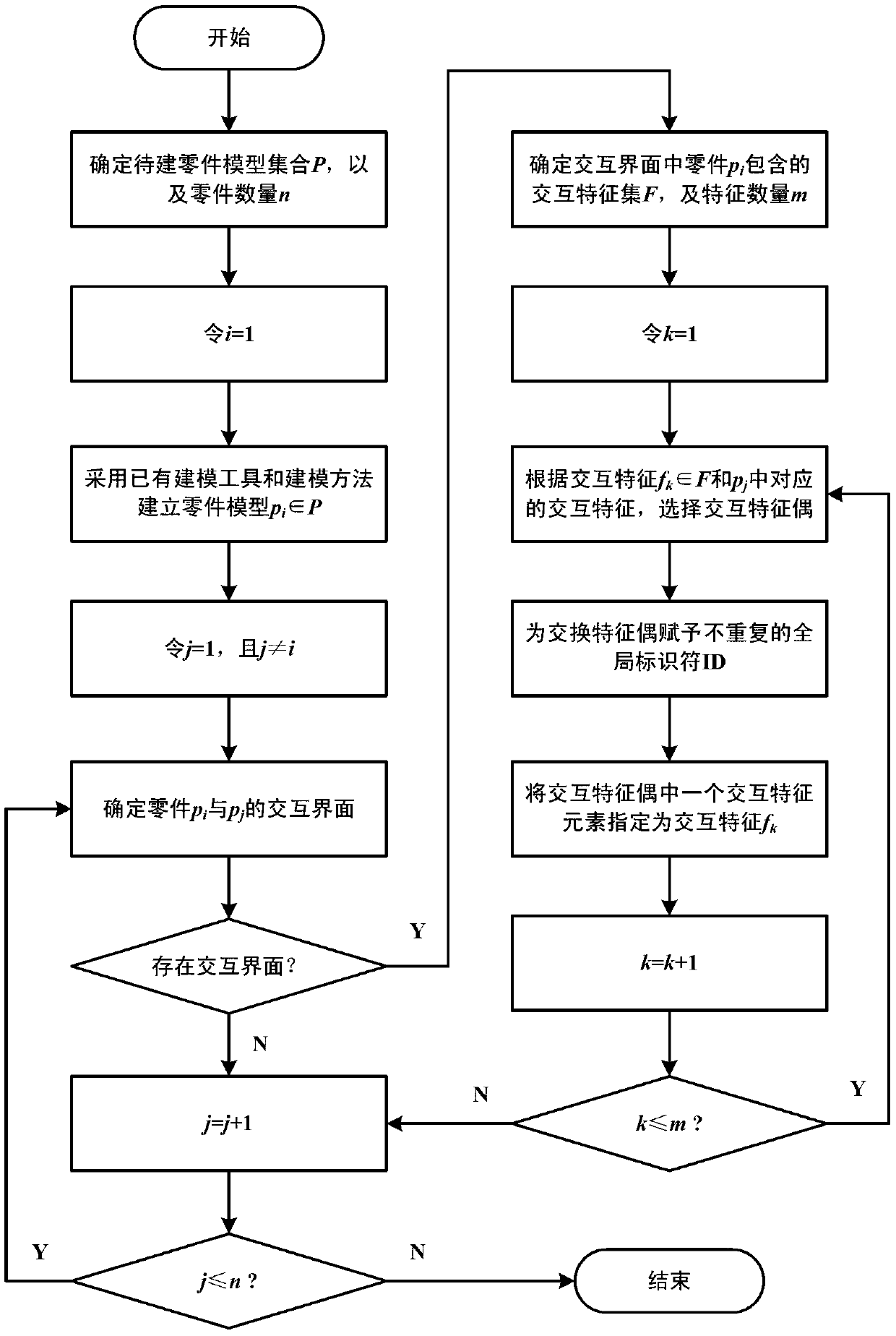

[0074] The specific steps of building part model platform 1 and top cone 2 and embedding interactive feature pairs in them are as follows:

[0075] Step 1.1: Determine the part model set P={platform 1, top cone 2}, the number of parts n=2;

[0076] Step 1.2: Select part model p 1 = Platform 1, use CATIA modeling tool to build part model p of platform 1 1 ;

[0077] Step 1.3: Determine the part model p 1 = platform 1 and part p 2 = the interactive interface of the top cone 2, if there is no interactive interface, then enter step 1.5, otherwise enter step 1.4;

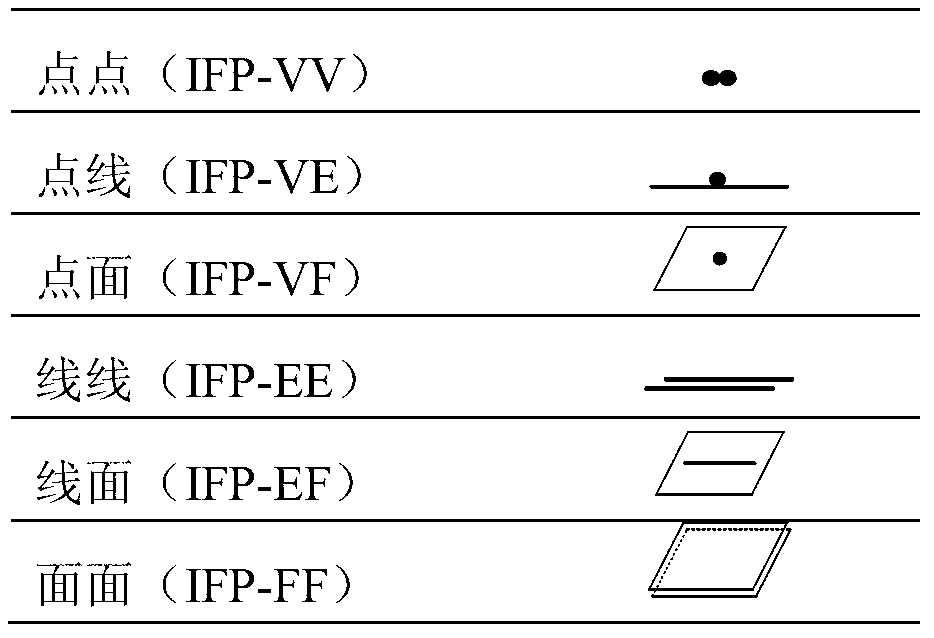

[0078] Step 1.4: Determine the part model p in the interactive interface 1 =interaction feature set F contained in platform 1={platform feature point 3, platform feature surface 4, platform feature line 5}, where the number of interaction features m=3;

[0079] ...

Embodiment 2

[0097] This implementation example is to establish the assembly model plate-cone 24 of the plate 19 and the flat-headed cone 20 based on the interaction feature pair.

[0098] The specific steps for establishing the part model flat plate 19 and flat head cone 20 and embedding interactive feature pairs therein are as follows:

[0099] Step 1.1: Determine the set of part models to be established P={flat plate 19, flat cone 20}, the number of parts n=2;

[0100] Step 1.2: Select part model p 1 = flat plate 19, adopt CATIA modeling tool to establish the part model p of flat plate 19 1 ;

[0101] Step 1.3: Determine the part model p 1 = plate 19 and part p 2 =The interactive interface of the flat cone 20, if there is no interactive interface, then enter step 1.5, otherwise enter step 1.4;

[0102] Step 1.4: Determine the part model p in the interactive interface 1 =interaction feature set F={plate feature surface 21} contained in the plate 19, wherein the number of interactiv...

Embodiment 3

[0116] This implementation example is to establish an assembly model plate-nail 37 of the plate with holes 31 and the nail 32 based on the interaction feature pair.

[0117] The specific steps for building the part model with holes 31 and nails 32 and embedding interactive features therein are as follows:

[0118] Step 1.1: Determine the set of part models to be established P={perforated plate 31, nail 32}, the number of parts n=2;

[0119] Step 1.2: Select part model p 1 =perforated plate 31, adopt CATIA modeling tool to set up the part model p of banded plate 31 1 ;

[0120] Step 1.3: Determine the part model p 1 = perforated plate 31 and part p 2 = nail 32 interactive interface, if there is no interactive interface, then enter step 1.5, otherwise enter step 1.4;

[0121] Step 1.4: Determine the part model p in the interactive interface 1=interaction feature set F={with plate hole feature line 33, with plate hole feature surface 34} contained in the plate with holes 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com