Turnover storing box for storing thin wafer

A technology of wafers and storage boxes, applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve the problems of collision, unsafe petri dishes, and excessive storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

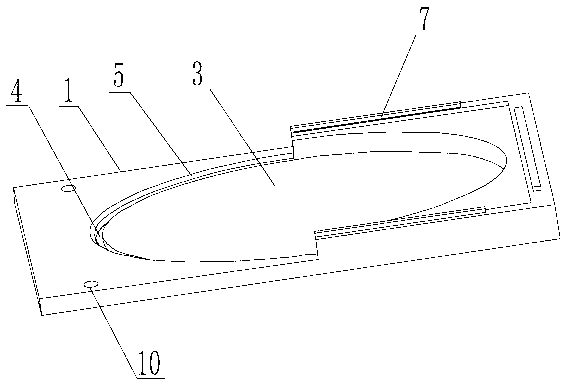

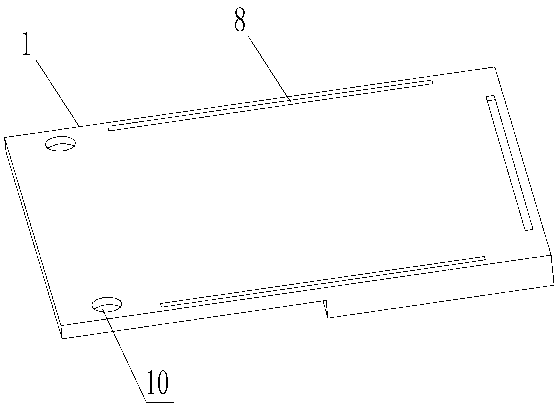

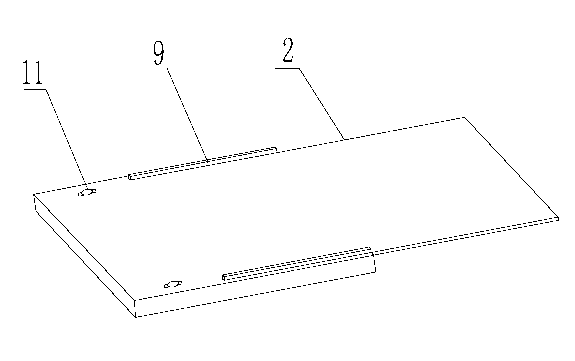

[0020] Such as Figure 1-4 As shown, a turnover storage box for storing thin wafers includes a box body and a box cover. The box body is provided with a cabin platform, the cabin platform is a smooth circular platform, the diameter of the platform is greater than the diameter of the thin wafer; the box body is divided into two parts, high and low, along the partial arc of the cabin platform periphery, and the The lower part of the body is provided with a pick-and-place opening, which is an arc-shaped groove arranged on the outside of the cabin platform. The cover is also divided into high and low parts, the low part of the box cover matches the high part of the box body, and the high part of the box cover matches the low part of the box body.

[0021] Such as Figure 1-2 As shown, the cabin is the most important part of the entire box, and its bottom is similar to a petri dish. The platform of the cabin is a smooth circular platform, and the diameter of the platform is sligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com