Lid-fastening structure

A technology of structure and tight cover, applied in the direction of substructure, superstructure, superstructure sub-assembly, etc., can solve the problems of enlarged working space, time-consuming assembly work, etc., and achieve the effect of easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

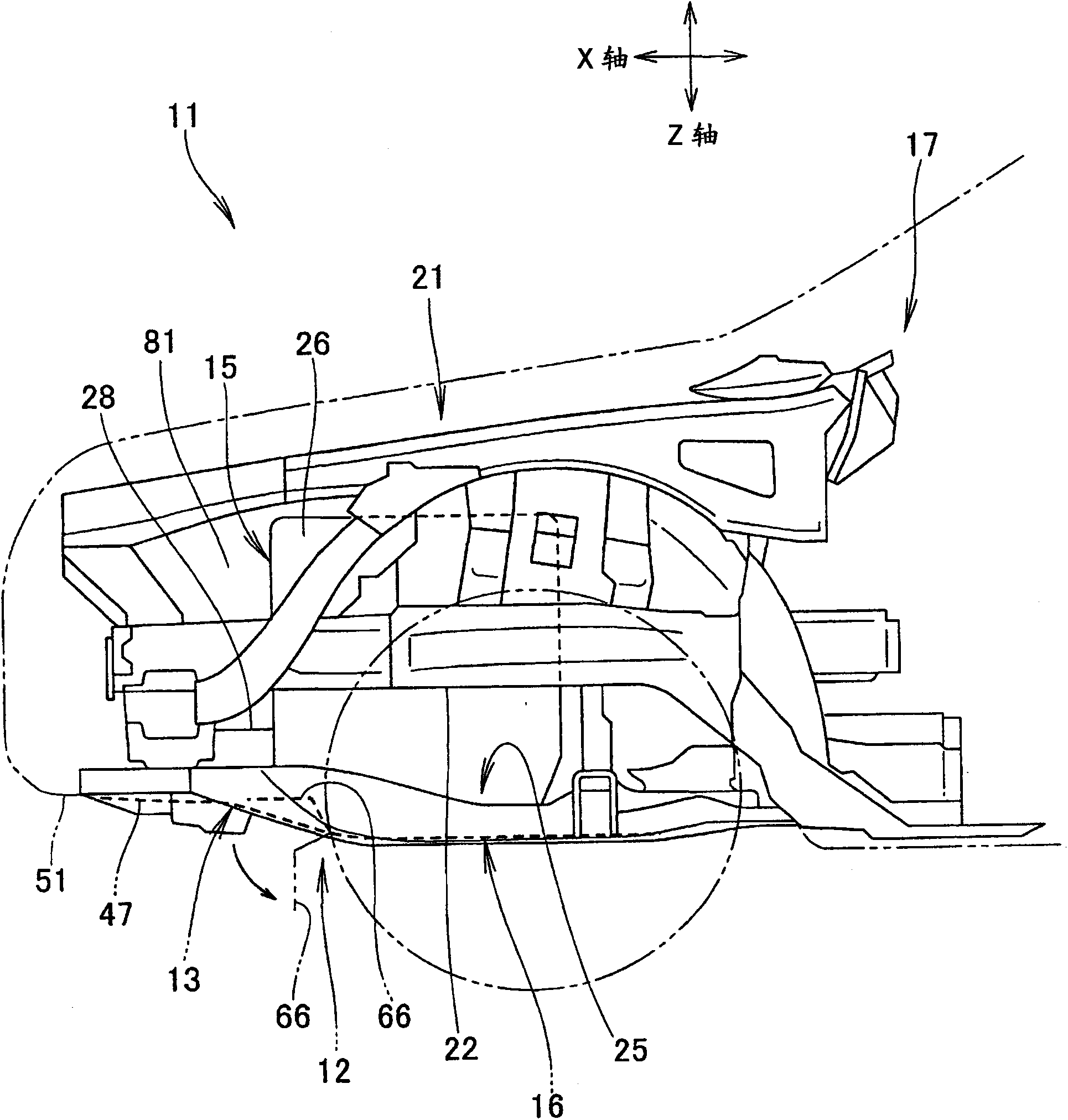

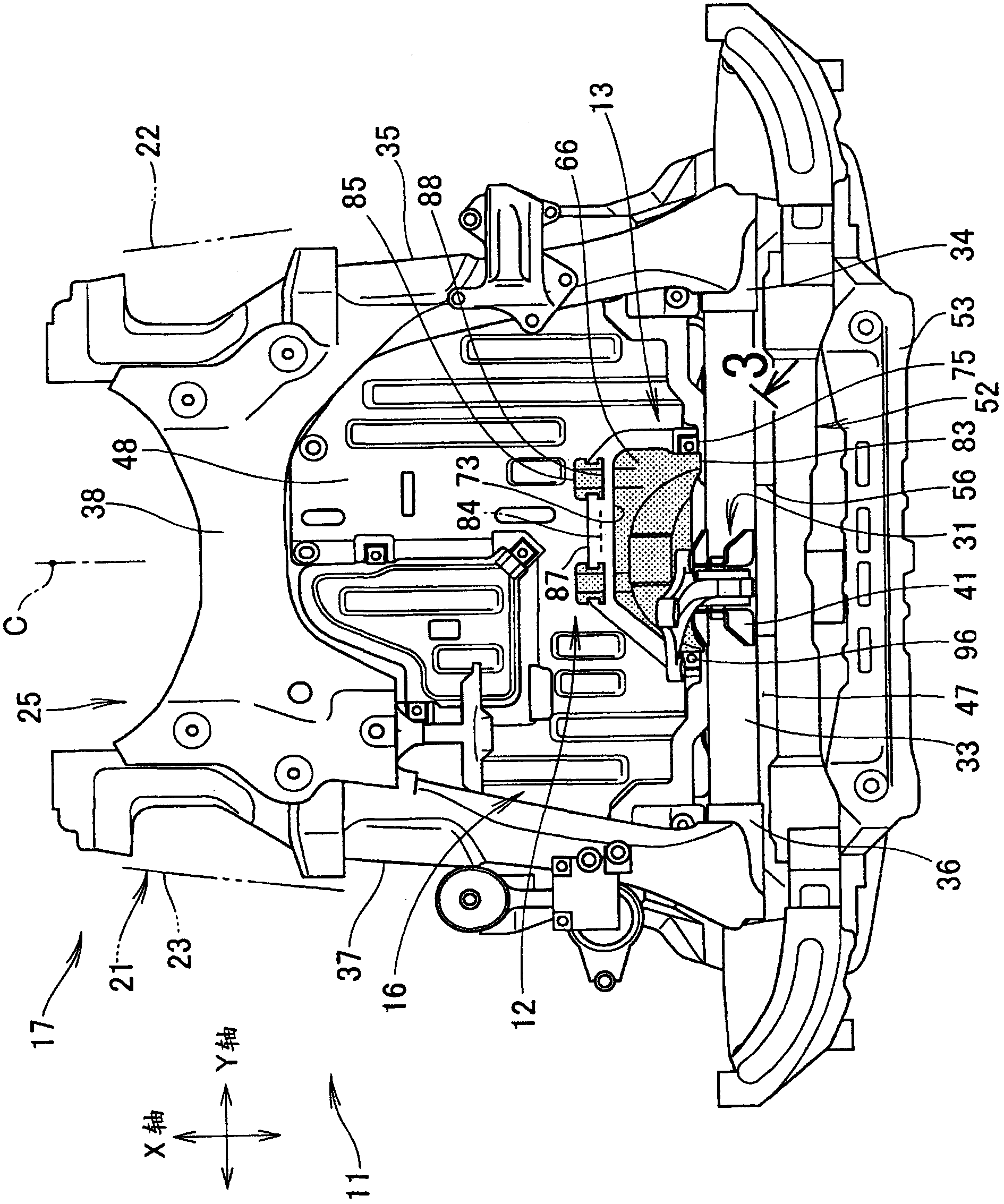

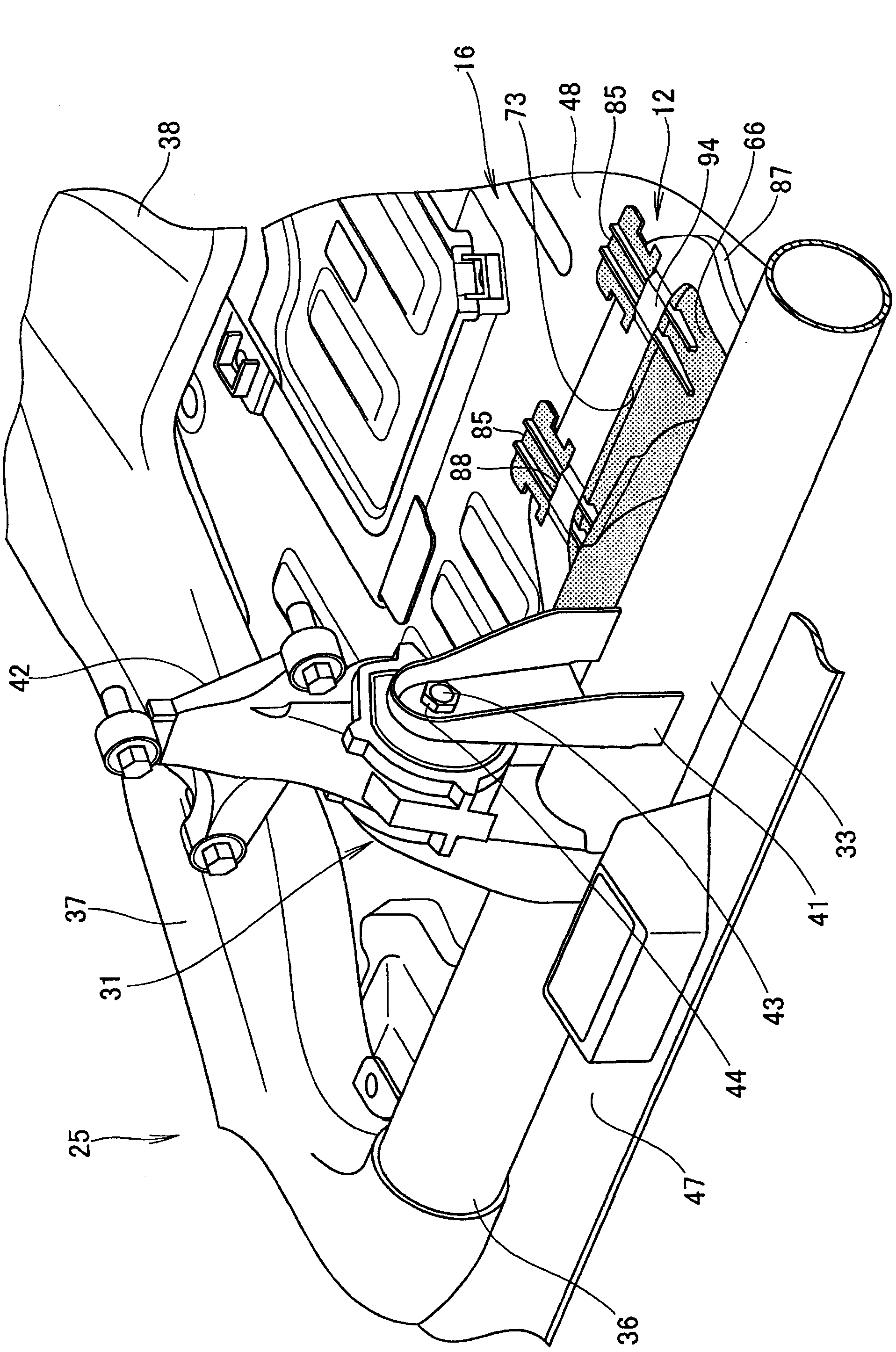

[0065] Such as figure 1 as well as figure 2 As shown, a vehicle 11 is provided with a cover structure 12 and a cover fastening structure 13 . The cover structure 12 and the cover fastening structure 13 are provided on the under cover 16 which covers the lower side of the engine 15 of the vehicle 11 .

[0066] The vehicle 11 includes a vehicle body 17 , a front body 21 of the body 17 , and an engine 15 supported by the front body 21 . The front body 21 includes: a left front side frame 22; a right side front side frame 23 substantially the same as the left side front side frame 22 ( figure 2 ); Assemble the front sub-frame 25 of the left and right front side frames 22,23 from below.

[0067] The right front side frame 23 is substantially symmetrical to the left side front side frame 22 with respect to the center C in the vehicle width direction.

[0068] The engine 15 is a transverse type. Pistons (not shown) of the engine main body 26 are arranged in the vehicle width d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com