Method for machining double-metal band saw blade

A bi-metal belt and band saw blade technology, applied in metal sawing equipment, metal processing equipment, tool manufacturing of sawing machine devices, etc., can solve the problems of high-speed steel waste, bad deformation, expensive equipment, etc. Power, combined with reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for processing a bimetallic band saw blade is characterized in that it comprises the following steps:

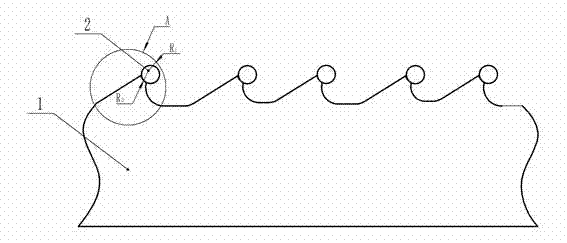

[0028] 1) Process the band saw blade body 1, and process a plurality of arcs on the welding surface at the top of the band saw blade body along the length direction of the band saw blade body 1;

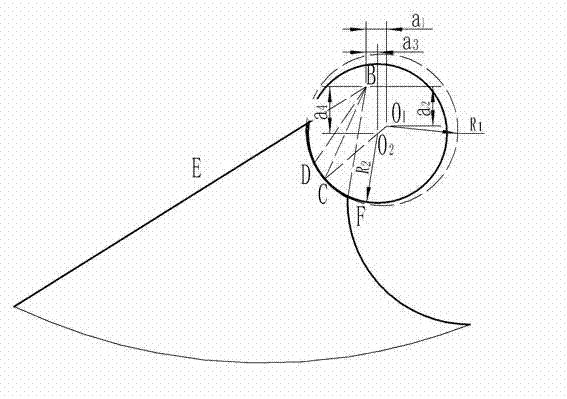

[0029] 2) Preset a high-speed steel particle 2 on each welding surface arc of the band saw blade body 1, and the welding surface arc radius R 1 with a spherical HSS particle radius R 2 The relationship between is: R 2 ≤R 1 ≤R 2 +0.5;

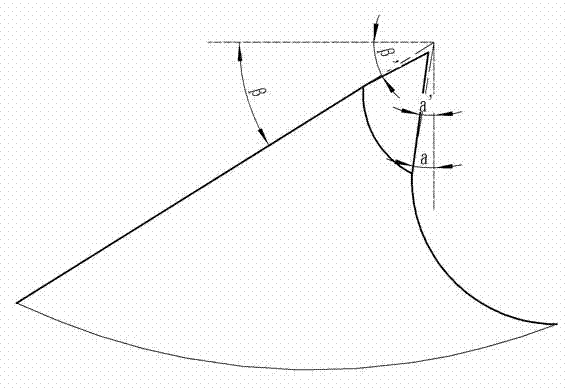

[0030] The center O of the arc of the welding surface of the band saw blade body 1 1 Placed on the band saw blade body 1 below the line BG between the front and rear blade faces and close to the rake face, and O 1 The distance a from BG in the length direction of the band saw blade 1 Meet: 0.1R 2 ≤a 1 ≤0.3R 2 ;

[0031] o 1 The distance a from BG in the width direction of the band saw blade 2 Meet: 0.5R 2 ≤a 2 ≤0.8R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com