Nondestructive testing robot for excavator

A non-destructive testing and robotic technology, applied in the field of robotics, can solve problems such as slow manual testing, unreliable consistency, and hydraulic oil spraying, and achieve the effects of improving testing reliability, reducing testing risks, and facilitating operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

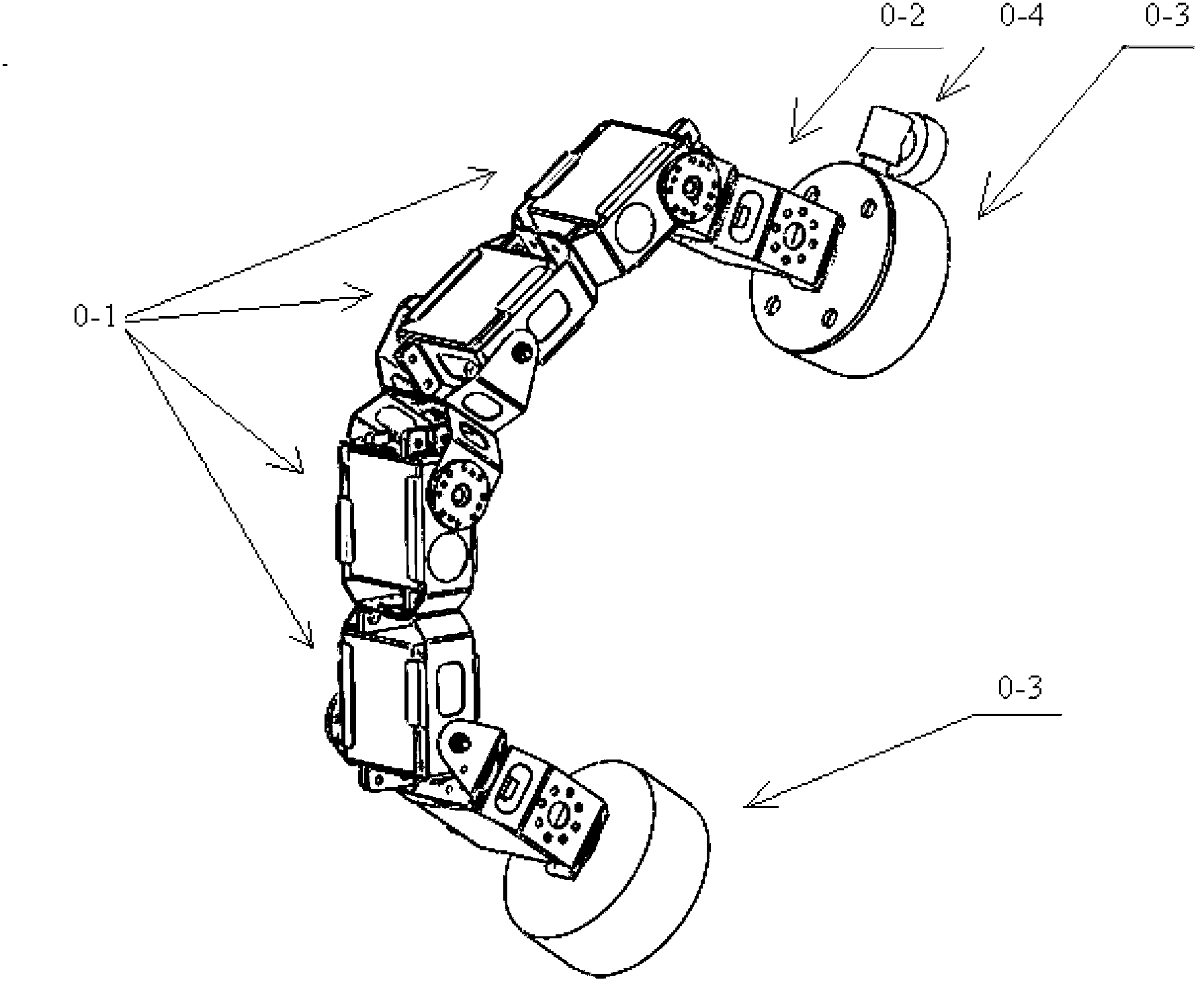

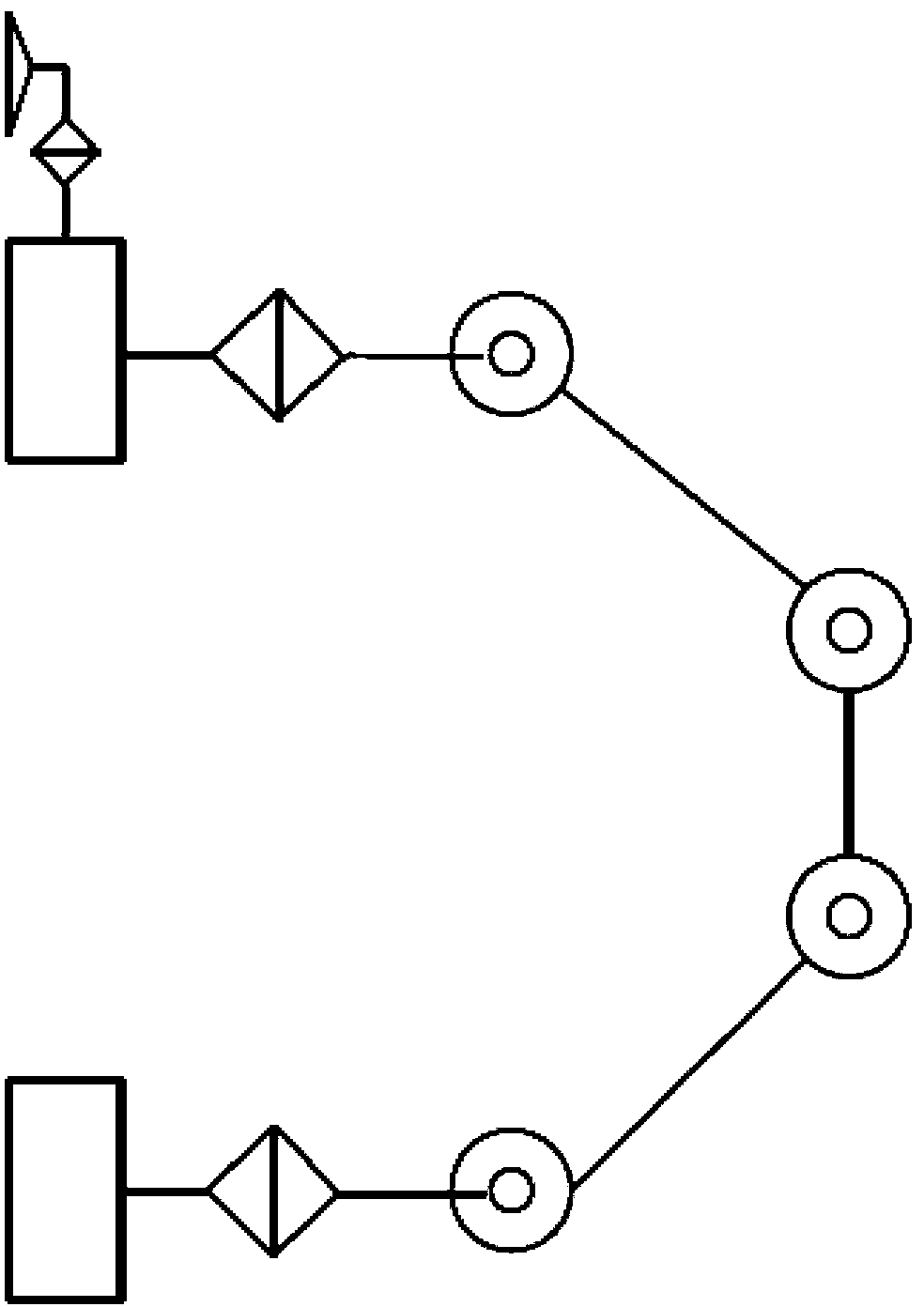

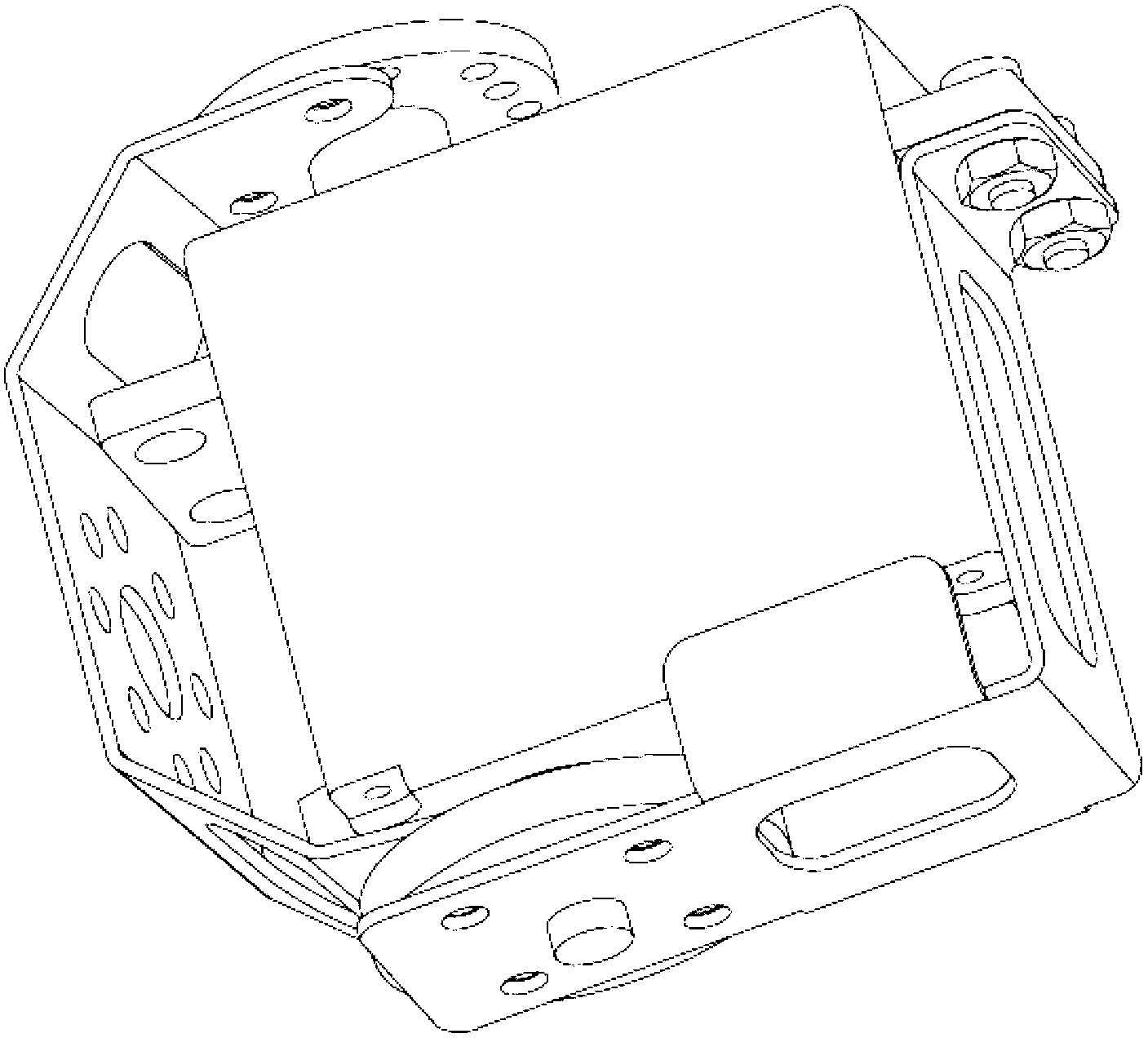

[0042] Such as figure 1 , figure 2 shown. The excavator non-destructive testing robot of the present invention includes a robot body and a detection system 0-4, the robot body includes six joint modules and two electromagnetic sucker modules 0-3; the joint module is divided into two I-type joint modules 0 -2 and four T-shaped joint modules 0-1; the four T-shaped joint modules 0-1 are sequentially connected in series to form two ends, and two I-shaped joint modules 0-2 are respectively connected to the two ends Actively connected; the two electromagnetic chuck modules 0-3 are respectively articulated with the two I-type joint modules 0-2; the detection system 0-4 (see Figure 10 ) including ultrasonic probe D-1 connected in sequence (see Figure 7 ), a data collector, and a remote controller. The ultrasonic probe D-1 is connected to one of the electromagnetic chuck modules 0-3 through a rotating shaft.

[0043] It can be seen from the above structure that the excavator non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com