Three-freedom-degree parallel robot wrists with aligning mechanisms

A technology of robot and degree of freedom, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems that the axes cannot be precisely intersected at one point, affect the operation accuracy of the robot wrist, and the load capacity is small, and achieve compact structure, good rigidity, and assembly easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

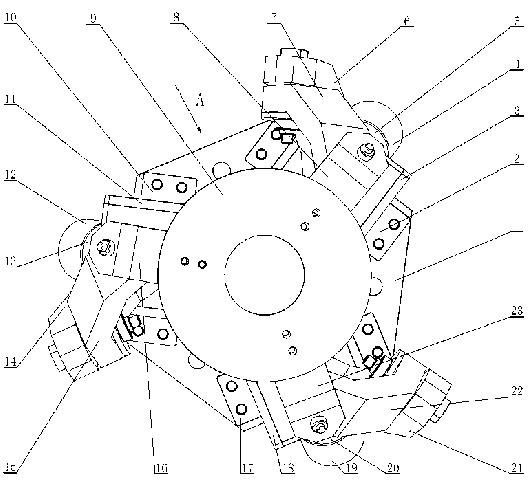

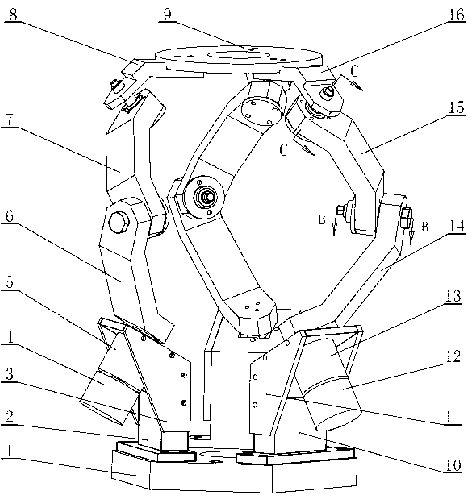

[0021] see figure 1 — Figure 4 , the three-degree-of-freedom parallel robot wrist with an aligning mechanism includes a base, a moving platform (9), three kinematic branch chains with an aligning mechanism, three spherical substructures, and three power sources; it is characterized in that : One end of the three motion branch chains with self-aligning mechanisms is respectively connected to the moving platform (9) through three spherical sub-structures, and the other end is connected to the power source mechanism, which is fixed on the base (1) by bolts. ), the three active links (6, 14, 21) in the three motion branch chains with self-aligning mechanisms are connected in series through three self-aligning mechanisms and three driven links (7, 15, 22); The three power sources directly drive three motion branch chains with self-aligning mechanisms to make the moving platform (9) move.

Embodiment 2

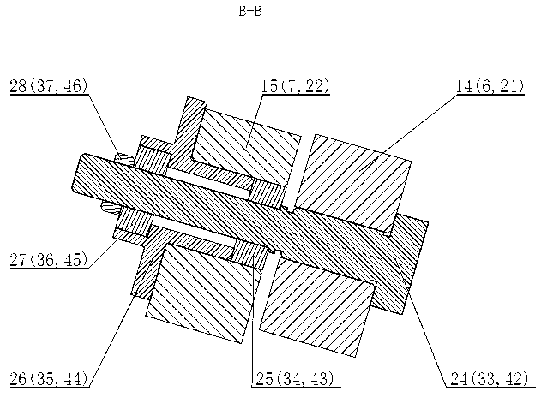

[0023] see figure 1 — Figure 4, this embodiment is basically the same as Embodiment 1, and the special feature is that: the first, second and third motors (4, 12, 19) are respectively connected with the first, second and third reducers (5 . Fixed on the upper surface of a base (1), the three motor support bases (2, 10, 17) are respectively connected with reinforcement plates (3, 11, 18) by screws and spaced 120° apart. One ends of the first, second and third moving platform connecting rods (8, 16, 23) are respectively fixed on the lower surface of the moving platform (9) by screws, and the three moving platform connecting rods (8, 16, 23) form an angle of 120° Evenly distributed in the circumferential direction, the other ends of the three moving platform connecting rods (8, 16, 23) respectively pass through the first, second and third spherical substructures and the driven connecting rods (7, 15, 22) of the three branch chains connect. The three spherical substructures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com