Three-dimensional prefabricating body of multi-shape section combination

A prefabricated and multi-shaped technology, applied in the field of three-dimensional prefabricated bodies, can solve the problems of overweight and large design allowance of casting components, and achieve the effects of reducing weight, reducing workload and reducing component volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

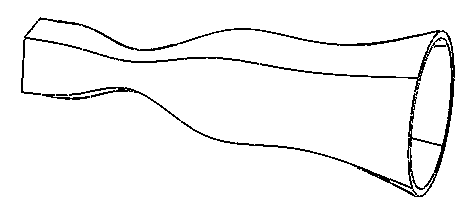

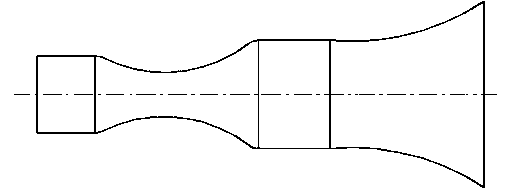

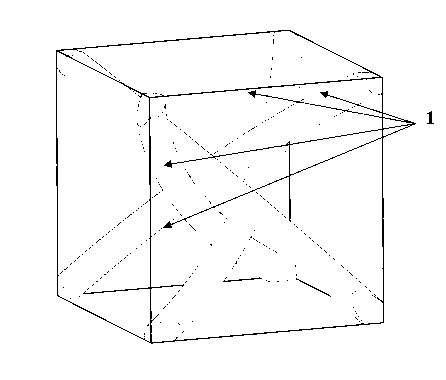

[0020] Such as Figure 1-3 As shown, a three-dimensional preform with a combination of multiple shapes and cross-sections, the cross-section of the three-dimensional preform is a special-shaped structure, which is formed by connecting four sections of different shapes in sequence, the first section is square, and the second section is contracted It consists of a curved surface and an expanded curved surface. The third cross-section is a square, and the fourth cross-section is an expanded curved surface. The preform is made of the same unit cell structure and is shaped and woven along the outside of the special-shaped core mold. Each unit cell structure contains four directions. The knitting yarn 1 arranged on the diagonal of the body, the four-way knitting yarn 1 is woven diagonally to form a spatial four-way structure.

[0021] The square height of the third cross sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com