Rail train exhaust emission device

A technology for rail trains and waste disposal, which is applied in the directions of transportation and packaging, railway car body parts, railway vehicle heating/cooling, etc. It can solve the problems affecting the comfort of rail cars, high operating costs, equipment maintenance, etc., and achieves simple structure, Less maintenance and less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the rail train waste discharge device of the present invention will be further described below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

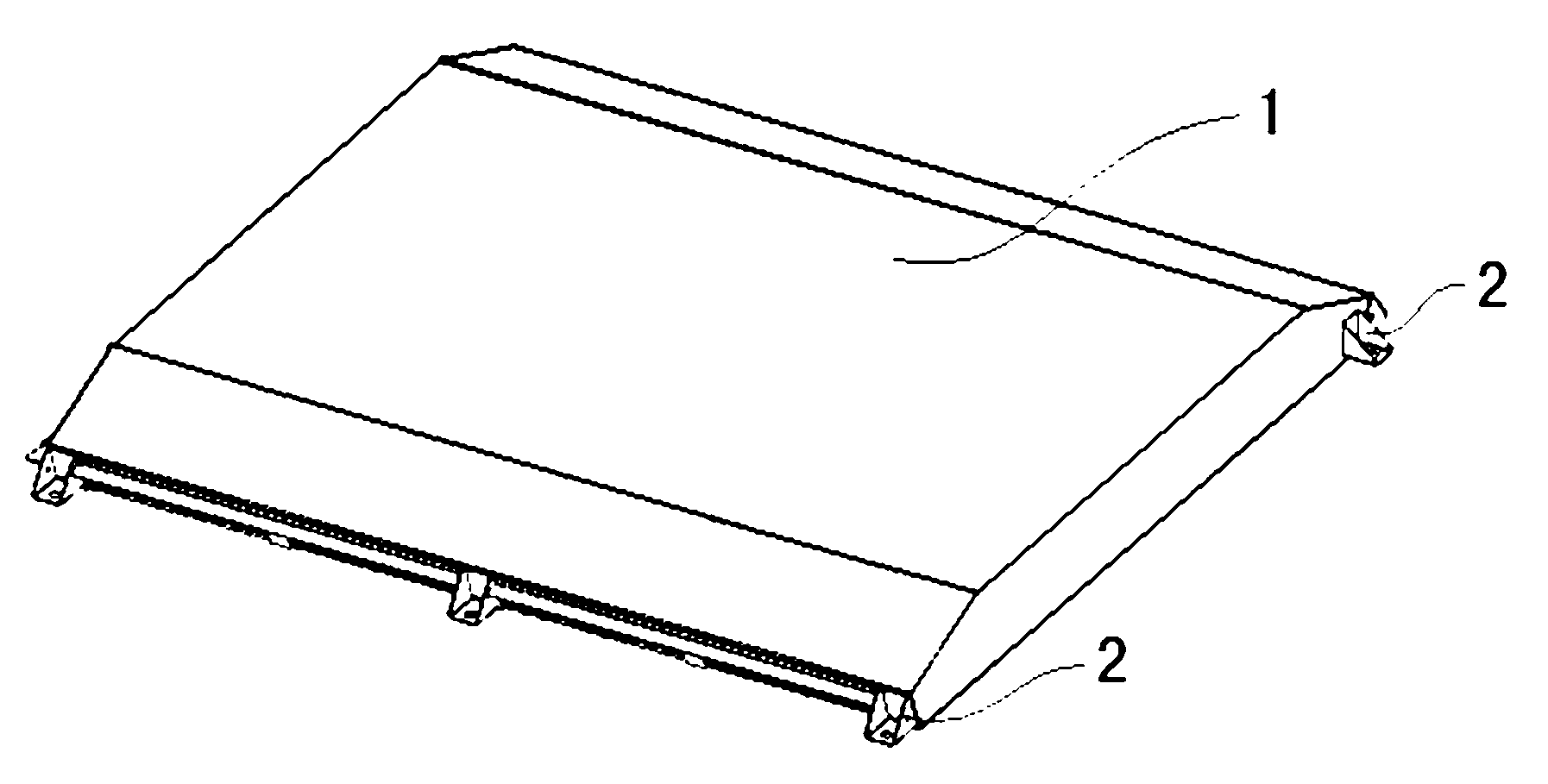

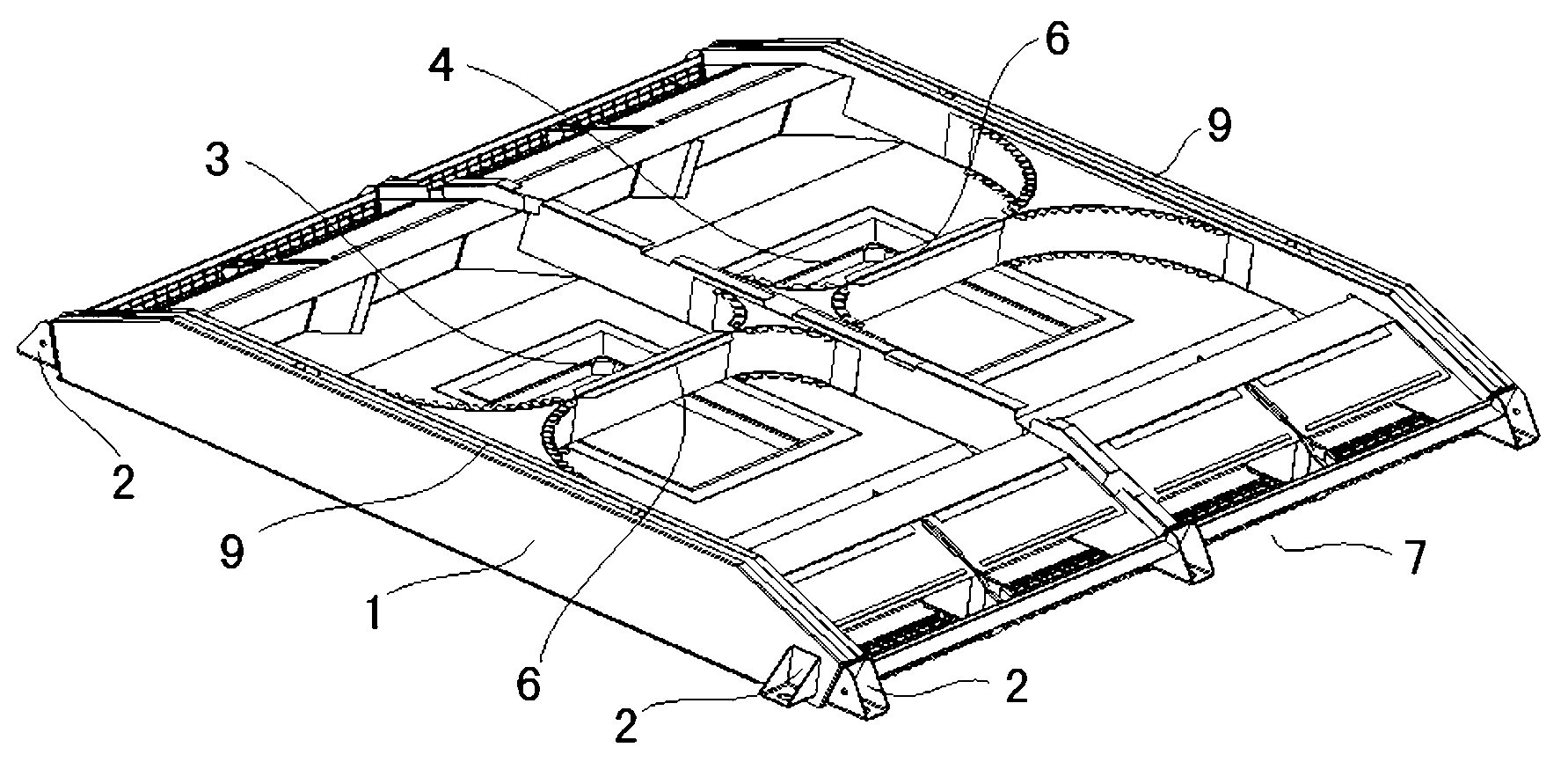

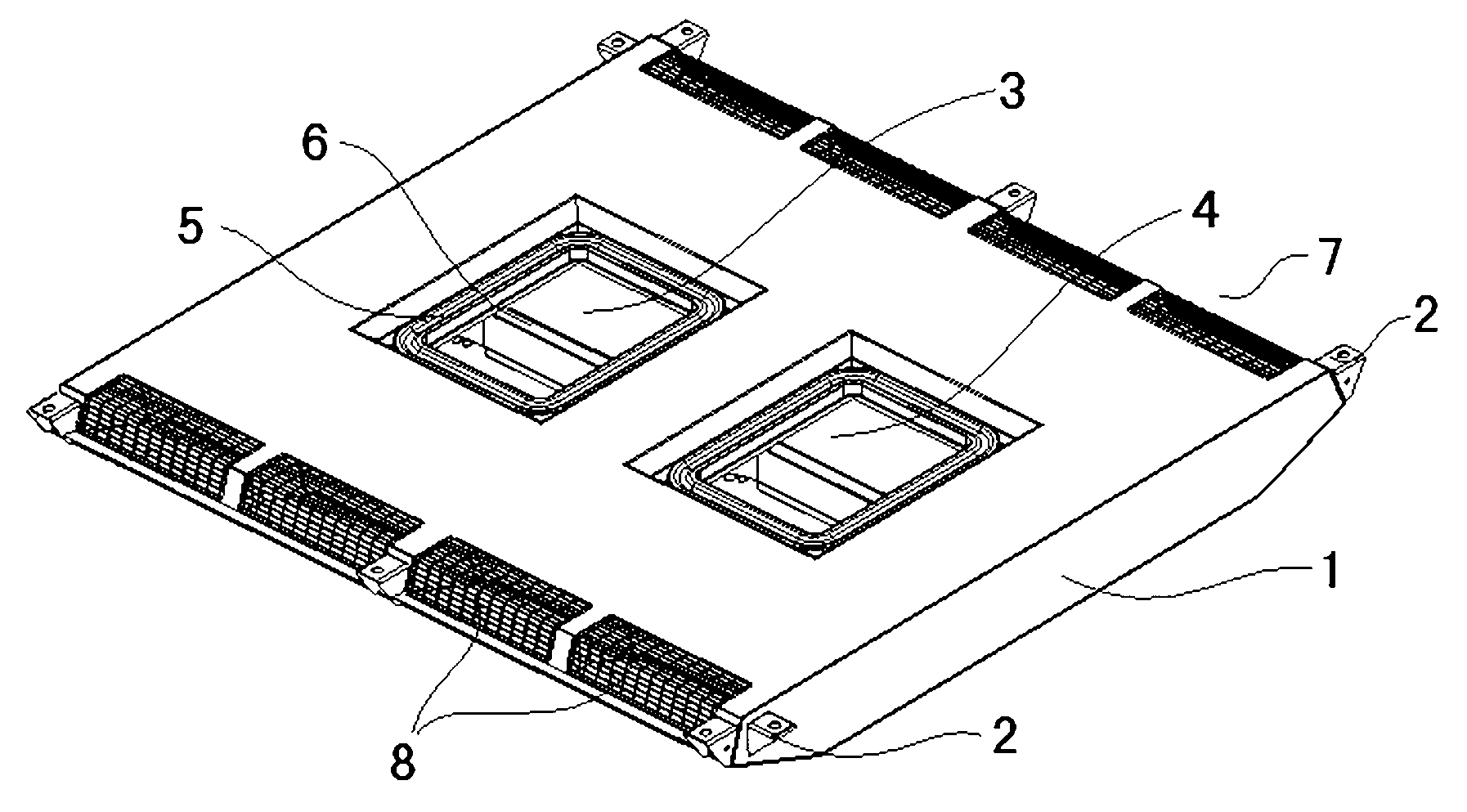

[0026] see figure 1 with 2 . A waste discharge device for rail trains, comprising a shell 1, hoisting feet 2 and an air return port structure, the shell 1 is a sandwich structure composed of two layers of sheet metal inside and outside, and the inner layer of sheet metal should be prepared first when manufacturing Then, make the outer sheet metal structure (cover) to form the shell 1, and then set a number of corresponding lifting feet 2 around the shell 1.

[0027] When making the inner layer sheet metal structure, set two return air outlets in the middle of the inner layer sheet metal, that is, the first air return port 3 and the second air return port 4, and then, in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com