Mobile hydraulic docking block and using method thereof

A docking pier and hydraulic technology, which is applied in the field of movable hydraulic docking pier, can solve the problems of high rental fee, error-prone, unsafe construction, etc., and achieve the effects of saving repair costs, preventing uneven force, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific technical solutions of the present invention will be described below in conjunction with the accompanying drawings.

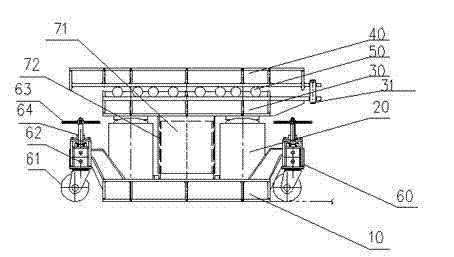

[0031] Such as figure 1 Shown is a movable hydraulic docking pier of the present invention, the hydraulic docking pier includes: a fixed support bracket 10, four hydraulic cylinders 20, a moving bracket 30 up and down, a horizontal moving bracket 40, and a steel ball special spacer Device 50 and running gear assembly 60.

[0032] On the four corners of the fixed support bracket 10 , a walking mechanism assembly 60 is respectively extended; the running mechanism assembly 60 includes traveling wheels 61 . Preferably, the traveling wheels 61 can move forward or move forward. Further, the traveling mechanism assembly 60 also includes: a positioning cross pin 62 , a hand wheel 63 and a movable handle 64 .

[0033] The four hydraulic cylinders 20 are used as four supporting points of the docking pier and are arranged on the four corners of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com