Automatic adjustment method and system of elevator starting torque

A technology of automatic adjustment and starting torque, which is applied in the field of elevator control to avoid slippage and increase comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

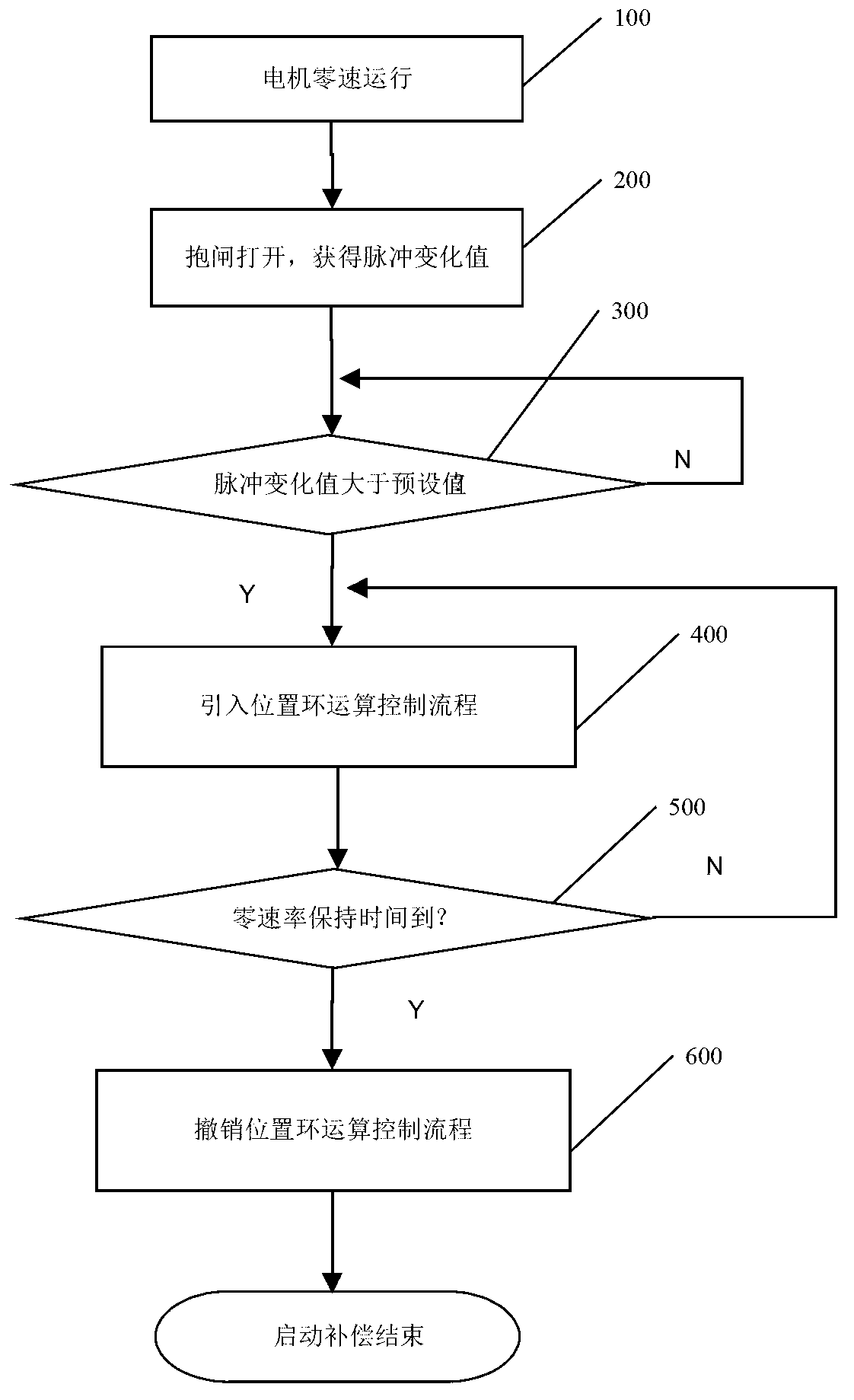

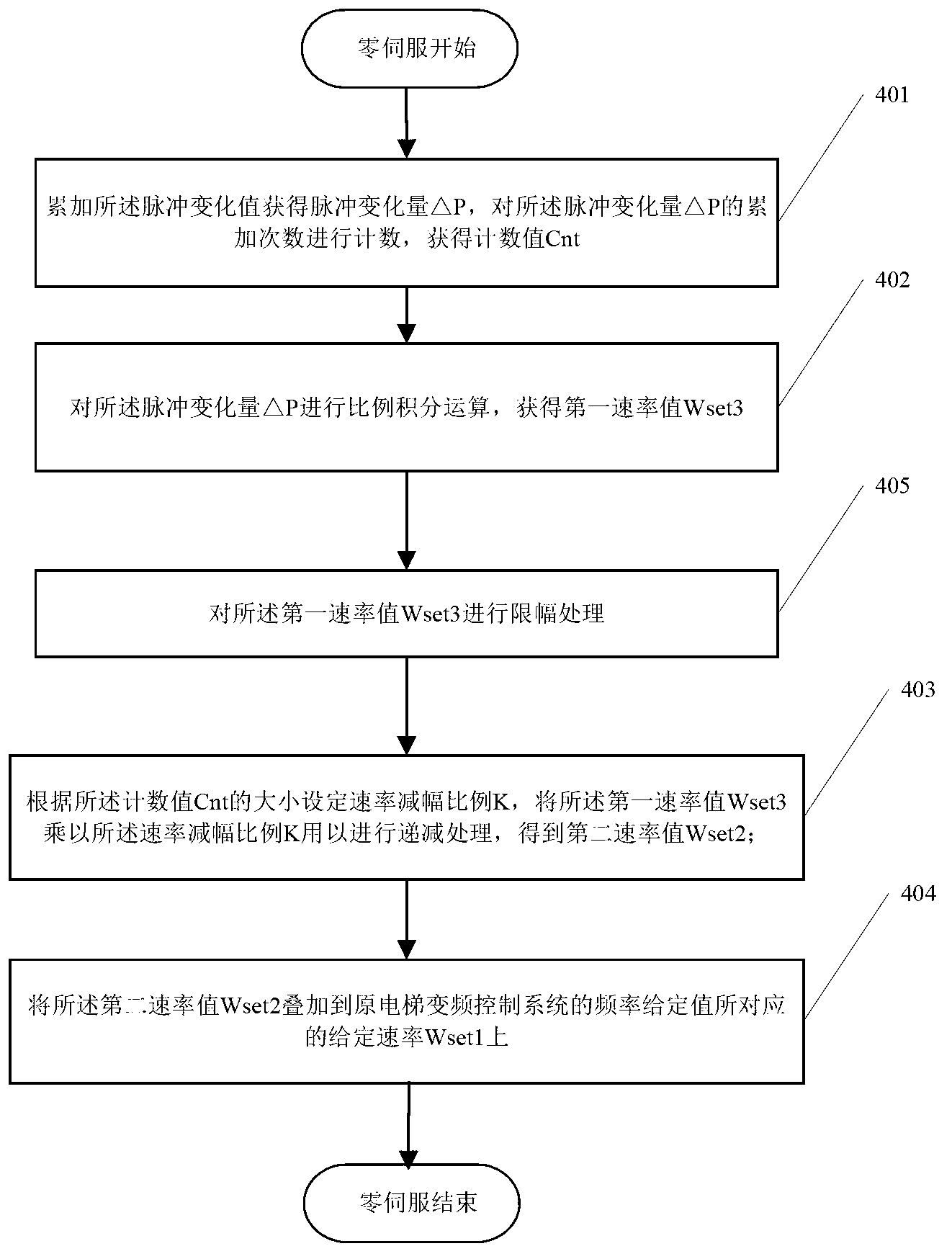

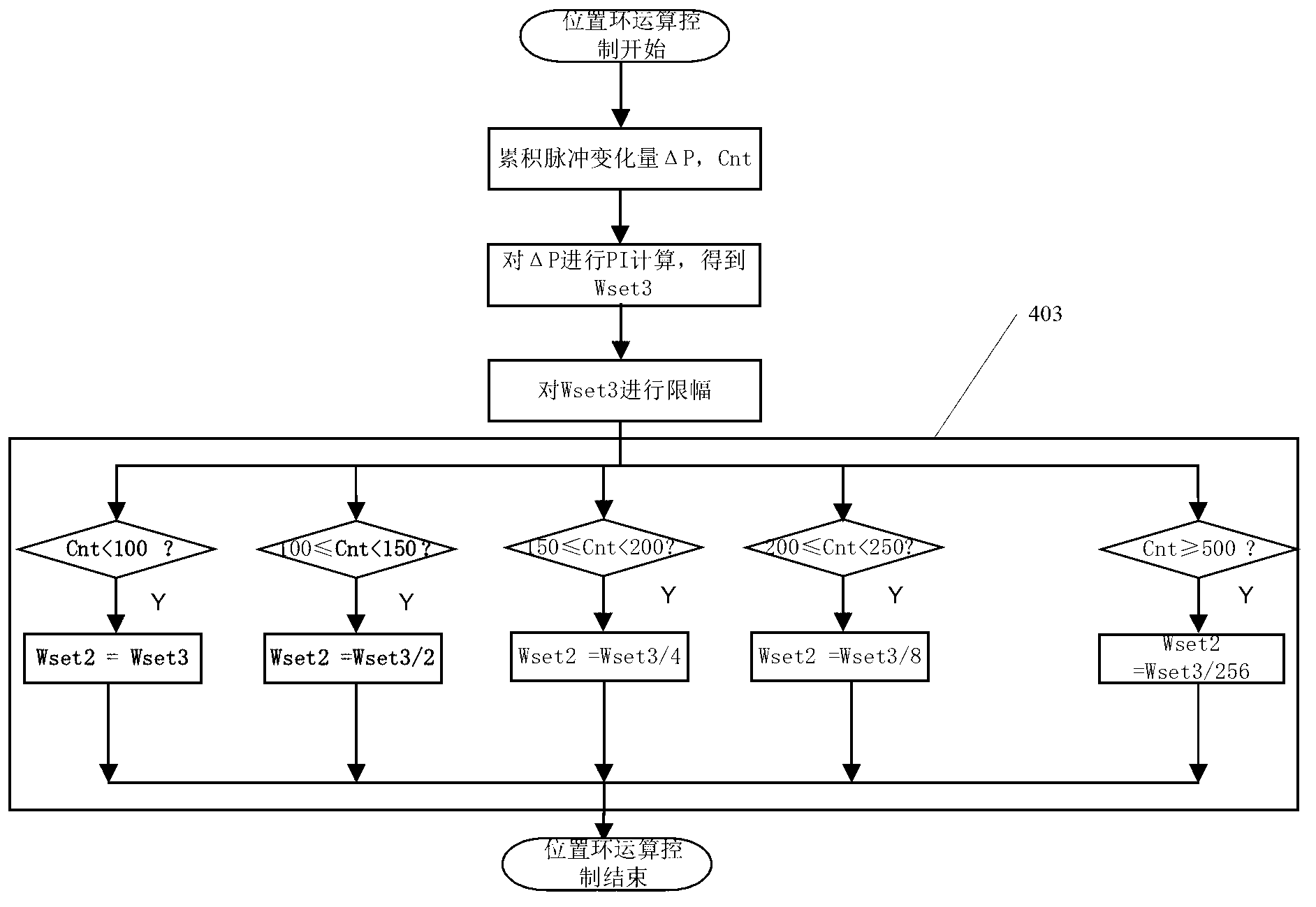

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] Such as Figure 4 As shown, the closed-loop vector control schematic diagram of the elevator frequency conversion control system is given. The usual original elevator frequency conversion control system mainly includes:

[0045] A frequency setting module 1, configured to set a given frequency, and obtain a given rate Wset1 according to the given frequency;

[0046] The negative feedback adjustment processing module 2 is configured to perform negative feedback adjustment processing on the motor based on speed loop proportional integral operation according to the given rate Wset1. In the negative feedback adjustment processing module 2, when there is no torque compensation, the operating frequency of the inverter is determined by the set frequency Wset1, usually before the brake is opened, the inverter is already running at zero speed, and the feedback is give...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com