A kind of production method of aluminized paper for beer labels, back-coated remoisture paint for aluminized paper, and aluminized paper

A production method and aluminized paper technology, applied in paper coating, papermaking, coating, etc., can solve problems such as poor flatness, high cost of steam rehumidification, poor printing suitability, etc., to reduce production costs and improve resistance Curlability and printability, moisture stability and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

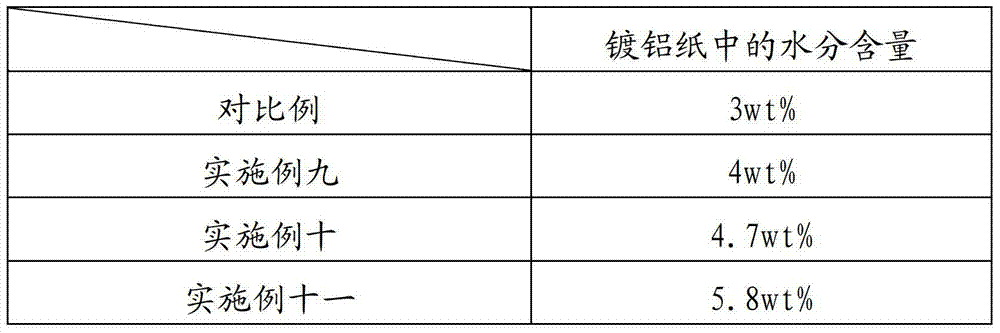

Examples

Embodiment 1

[0020] The invention relates to an aluminized paper for beer labels. The back of the aluminized paper is provided with a rewetting paint layer, and the rewetting paint layer contains glycol, ethanol and pure water.

Embodiment 2

[0022] A back-coated remoisture coating for aluminized paper for beer labels, comprising the following components: 3% ethylene glycol, 20% ethanol and 77% pure water, and the percentages are percentages by weight.

Embodiment 3

[0024] A back-coated remoisture coating for aluminized paper for beer labels, comprising the following components: 8% propylene glycol, 12% ethanol and 80% pure water, and the percentages are percentages by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com