Method for judging full profile control degree of water injection well

A discrimination method and technology for water injection wells, applied in the direction of earthwork drilling, borehole/well components, production fluid, etc., can solve the problem of inability to accurately judge the adequacy of profile control, the inability to satisfy the judgment of the adequacy of profile control of water wells, and the inability of water absorption profiles of water wells. Uniformity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

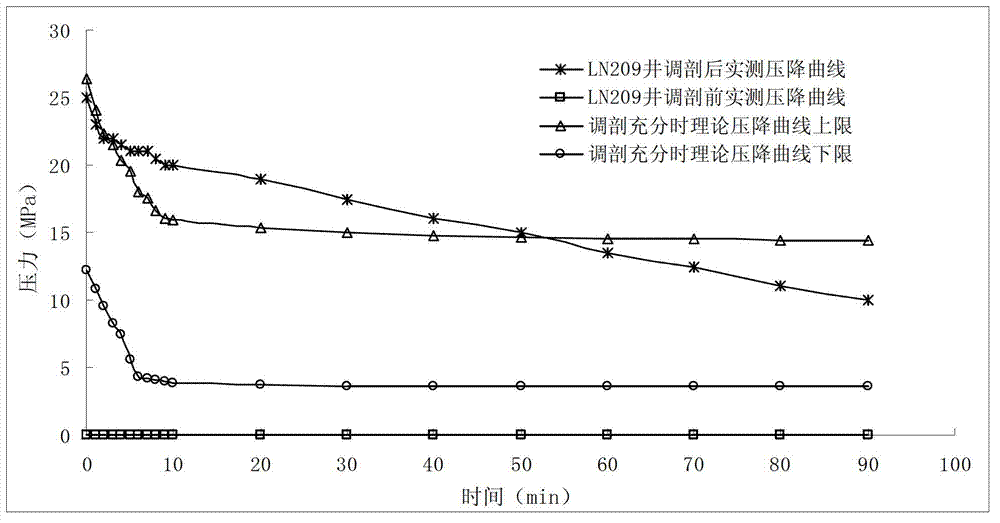

[0054] Taking the profile control of Well LN209 in Lunnan Oilfield as an example, it will be described in detail.

[0055] Well LN209 is a water injection well in the TI oil group in the structure 2 well area of Lunnan Oilfield. The geological reserves of the TI oil reservoir are 12.36 million tons, with an average porosity of 17% and an average permeability of 227mD. The well has accumulated 778,500 cubic meters of water injection before profile control,

[0056] The well drilled 5 sublayers with a total of 11.9m of oil layer for water injection. The water absorption profile before profile control in July 2010 showed that the main water absorption interval of the well was 4732.0-4737.5m, with a thickness of 5.5m. The relative water absorption was 74.98%, and the absolute water absorption The volume is 242.92m 3 / d, the water absorption profile is extremely uneven.

[0057] With the method of the present invention and the measured data before and after the profile control,...

Embodiment 2

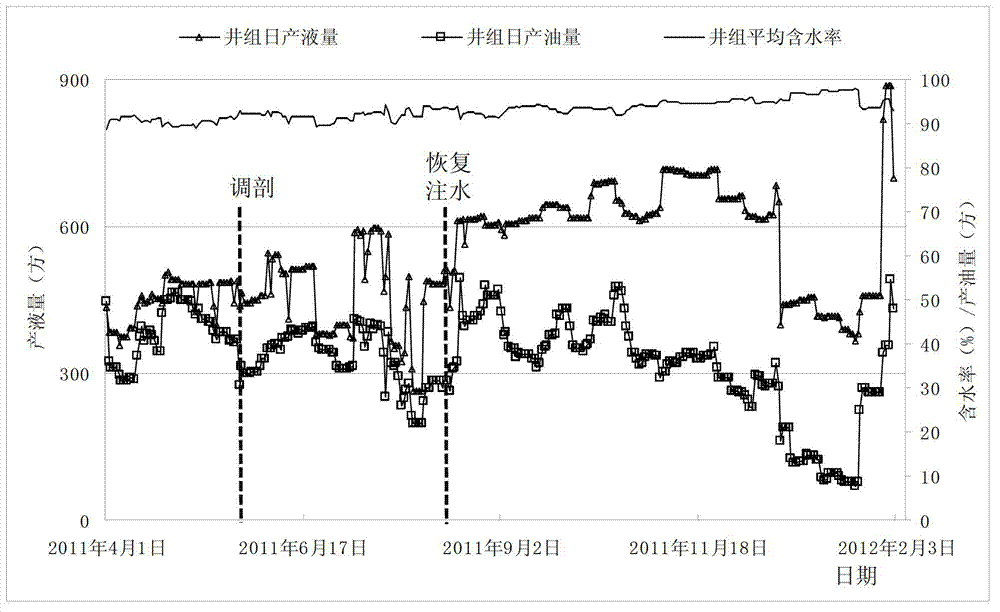

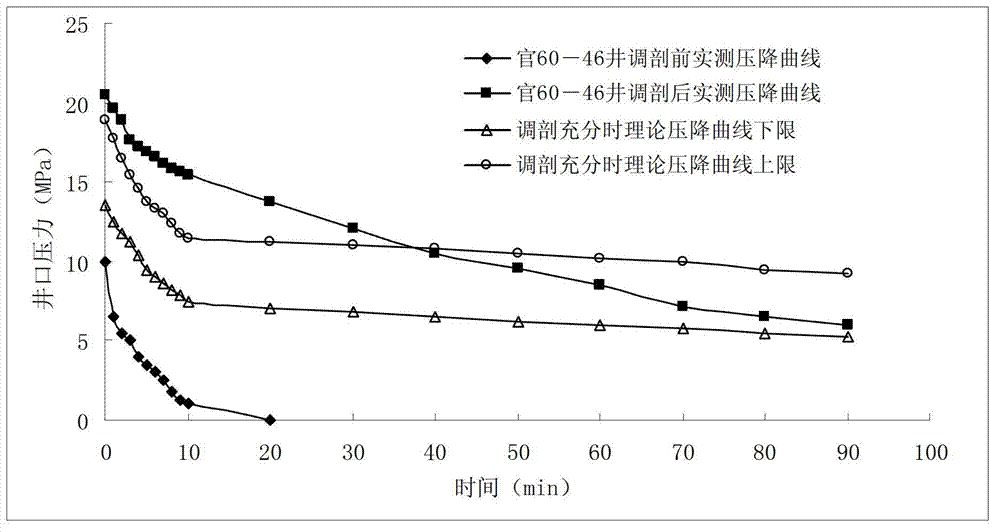

[0060] Taking the Guan 60-46 profile control well group in Dagang Oilfield as an example, it will be described in detail.

[0061] The well group is located in the east of the Wang 102-1 fault block, with geological reserves of 360,000 tons, recoverable reserves of 91,000 tons, and remaining recoverable reserves of 60,600 tons; the average porosity is 22.1%, and the average permeability is 186.4mD. Before profile control, the accumulative fluid production of the well group was 37,600 cubic meters, the cumulative water injection was 37,000 cubic meters, and the cumulative injection-production ratio was 0.98. A total of 12 sublayers were drilled in the well, and a total of 59.1m oil layers were injected for general water injection. Before profile control, the water absorption profile showed two high water absorption layers, and their relative water absorptions were 54.28% and 23.52%, respectively, and the rest of the sublayers absorbed little or no water. , The water absorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average permeability | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com