Excavator suspension wear resistance method and excavator wear resistance device for implementing it

A wear-resistant, excavator technology, used in earth-moving drilling, slitting machinery, etc., can solve problems such as damage to equipment parts, scratches or grooves, and contact surface damage, achieve convenient and flexible operation, improve work efficiency, The effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

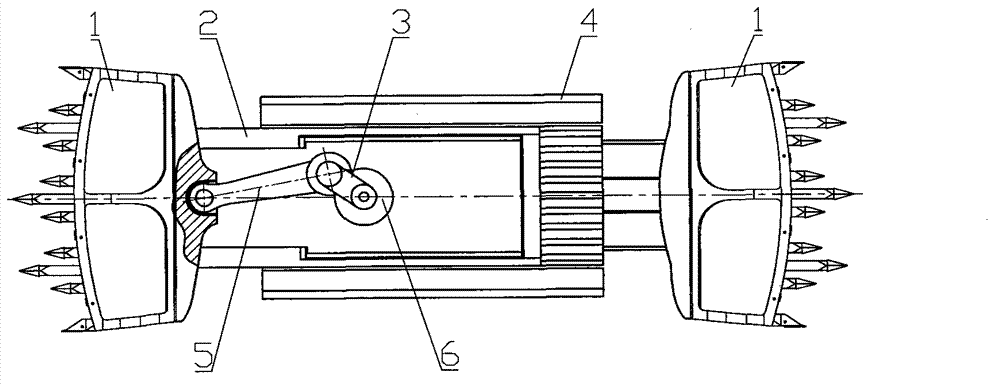

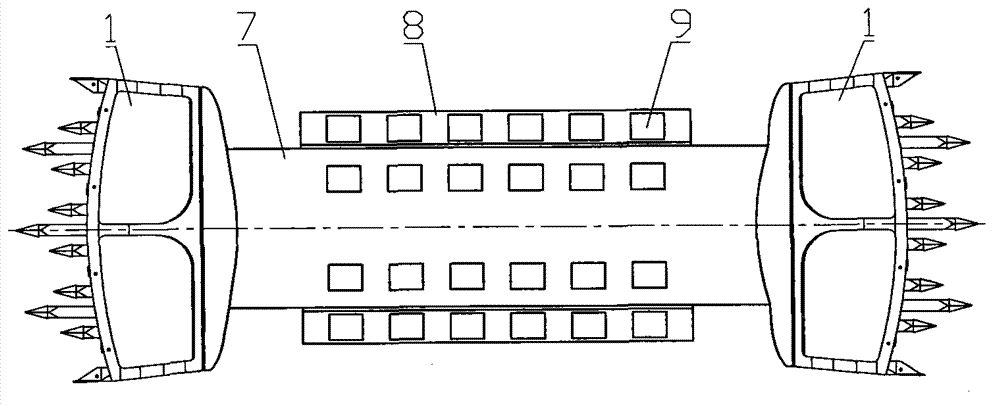

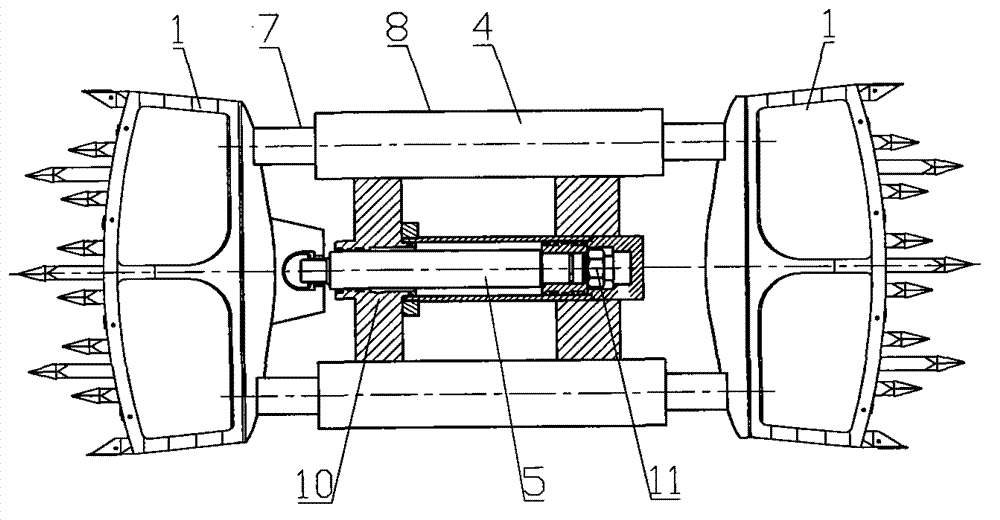

[0045] Figure 1 to Figure 3 It is the mining machine wear-resistant device described in Example 1, the mining machine wear-resistant device includes a driving mechanism 6, a friction mechanism 2, a mining mechanism 1, etc., and the friction mechanism 2 includes an impact guide 7, a guide support 8, etc. , the drive mechanism 6 includes a power impact member 5, such as image 3 As shown, the drive mechanism 6 also includes a power support 10 and the like. In this example, if figure 1 The driving mechanism 6 shown is a crank driving mechanism 6, and the crank driving mechanism 6 includes a crank 3, a connecting rod and the like. Such as image 3 As shown, the drive mechanism 6 is a hydraulic drive mechanism 11, etc., the impact guide 7 is arranged on the guide support 8, and the impact guide 7 plays a guiding role in the reciprocating movement of the mining mechanism 1, and both ends of the impact guide 7 are provided There is an excavation mechanism 1, the impact guide 7 i...

Embodiment 2

[0054] Figure 1 to Figure 2 It is the mining machine wear-resistant device described in Example 1. Such as Figure 4 Shown, suspension mechanism 9 is magnetic suspension mechanism 12, and magnetic suspension mechanism 12 comprises electromagnetic suspension mechanism 15 or permanent magnetic suspension mechanism 17, and electromagnetic suspension mechanism 15 comprises electromagnetic 16, and permanent magnetic suspension mechanism 17 comprises permanent magnet 20, and electromagnetic suspension mechanism 16 or permanent magnet 20 are arranged on On the impact guide 7 and / or the guide support 8, the magnetic poles arranged on the impact guide 7 and the guide support 8 have the same polarity, so as to reduce the positive pressure by utilizing the principle that the same-sex magnetic poles repel each other.

[0055] Such as Figure 5 As shown, the air suspension mechanism 9 includes a gas source, a control valve, a delivery pipeline, a gas chamber 29 and a nozzle 13, etc., th...

Embodiment 3

[0060] Figure 6 to Figure 9 It is the mining machine wear-resistant device described in Embodiment 3. Such as Figure 6 As shown, the magnetic levitation mechanism 12 includes an N-pole electromagnetic 16, an N-pole permanent magnet 18 is set on the impact guide 7, an N-pole electromagnetic 16 is provided on the guide support 8 or an N-pole electromagnetic 16 is set on the impact guide 7, and the guide An N-pole electromagnetic 16 is arranged on the support member 8, and the N-pole permanent magnet 18 or the electromagnetic 16 and the N-pole electromagnetic 16 are homosexually repelled to generate suspension. The power impact member 5 drives the impact guide 7 to reciprocate, and the impact guide 7 and the guide support 8 suspension friction reciprocating motion.

[0061] Such as Figure 7 As shown, the magnetic levitation mechanism 12 includes an electromagnetic S pole electromagnetic 16, an S pole permanent magnet 19 is set on the impact guide 7, an S pole electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com