Coupler connecting structure applicable to switching of backpressure rotors of low-pressure cylinder

A connection structure, low-pressure rotor technology, applied in the direction of machine/engine, blade support element, mechanical equipment, etc., can solve the key problem of backrest wheel connection is difficult, there is no breakthrough progress, etc., to meet the connection requirements, good Interchangeability, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

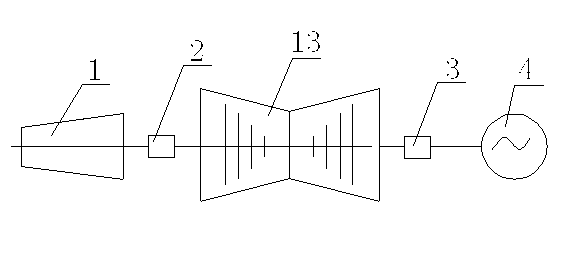

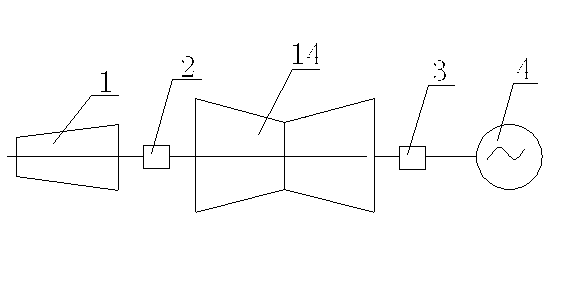

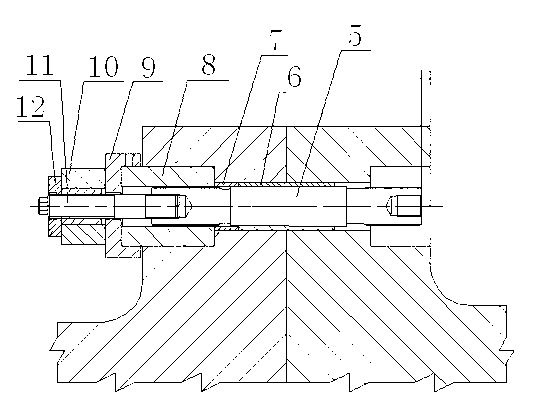

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a high and medium pressure rotor 1, the high and medium pressure rotor 1 is connected to one end of the low pressure rotor through the first coupling 2, and the other end of the low pressure rotor is connected to the generator 4 through the second coupling 3, the first coupling 2 and the second Couplings 3 are respectively provided with first tension bolts 5, and taper sleeves 6 are vertically set on the first tension bolts 5. Taper sleeves 6 are connected with support rings 7, and support rings 7 are connected with support blocks 8 to support A pad 9 is assembled on the block 8, and a hydraulic head 10 is installed on the pad 9. The supporting block 8 , the cushion block 9 , and the hydraulic head 10 are pierced with a second tension bolt 11 , and the second tension bolt 11 is connected with the first tension bolt 5 . A gland 12 is installed on the hydraulic head 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com