High-pressure delivery pipeline

A high-pressure conveying pipe, round tube-shaped technology, applied in the direction of pipes/pipe joints/pipe fittings, threaded connections, passing elements, etc., can solve the problems of complex pipe end structure sealing structure, oil pipeline pressure bearing, high stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

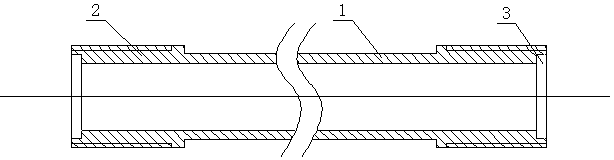

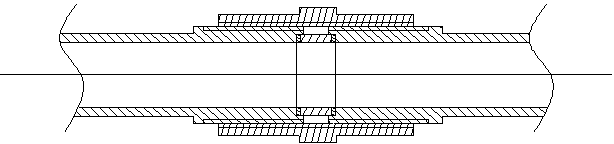

[0014] Such as Figure 1-2 As shown, a high-pressure delivery pipeline described in the embodiment of the present invention includes a body 1, which is in the shape of a round tube. Concave round table 3, the radial width of the inner concave round table 3 is equal to the wall thickness of the middle part of the body, and external threads are provided on the thickened outer walls 2 at both ends of the body 1, and the thickness of the thickened outer wall 2 of the body 1 is the same as that of the middle part of the body more than twice the wall thickness.

[0015] The axial width of the concave circular table is more than twice the thickness of the thickened outer wall, and the axial width of the concave circular table is less than the length of the external thread of the thickened outer wall, so as to ensure that the concave circular table has enough space to accommodate the seal Pad and pipe construction.

[0016] The length of the external thread is less than the length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com