Air-liquid separator used for air conditioner

A gas-liquid separator and air-conditioning technology, applied in the field of gas-liquid separators and air-conditioning gas-liquid separators, can solve the problem of reducing the effective volume, difficult to ensure the smooth flow of refrigeration oil back to the compressor, occupying the internal space of the gas-liquid separator, etc. problems, to ensure reliability, meet market demand, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

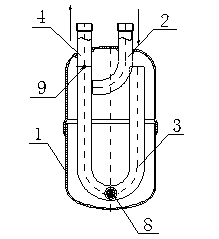

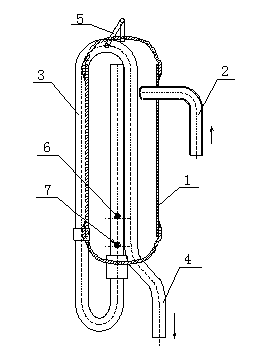

[0022] The air-conditioning gas-liquid separator of this embodiment includes a cylinder body 1, an air inlet pipe 2 and an air outlet pipe 4 with a U-shaped pipe 3, the U-shaped pipe 3 is arranged on the outside of the cylinder body 1, and the air outlet pipe 4 and the cylinder body 1 A pressure equalizing tube 5 is arranged between them, and the pressure equalizing tube 5 communicates with the air outlet pipe 4 and the inner cavity of the cylinder body 1. Two oil return holes are set on the air outlet pipe 4, the upper oil return hole 6 and the lower oil return hole 7, the diameter of the upper oil return hole 6 is smaller than the diameter of the lower oil return hole 7, the diameter of the upper oil return hole 6 is 1.5mm, and the lower oil return hole The diameter of the hole 7 is 2.0mm, the distance between the upper oil return hole 6 and the lower oil return hole 7 is 30mm, and the distance between the lower oil return hole 7 and the bottom of the cylinder body 1 is 20mm....

Embodiment 2

[0025] The air-conditioning gas-liquid separator of this embodiment includes a cylinder body 1, an air inlet pipe 2 and an air outlet pipe 4 with a U-shaped pipe 3, the U-shaped pipe 3 is arranged on the outside of the cylinder body 1, and the air outlet pipe 4 and the cylinder body 1 A pressure equalizing tube 5 is arranged between them, and the pressure equalizing tube 5 communicates with the air outlet pipe 4 and the inner cavity of the cylinder body 1. Two oil return holes are set on the air outlet pipe 4, the upper oil return hole 6 and the lower oil return hole 7, the diameter of the upper oil return hole 6 is smaller than the diameter of the lower oil return hole 7, the diameter of the upper oil return hole 6 is 1.0mm, and the lower oil return hole The diameter of the hole 7 is 1.5mm, the distance between the upper oil return hole 6 and the lower oil return hole 7 is 25mm, and the distance between the lower oil return hole 7 and the bottom of the cylinder body 1 is 15mm....

Embodiment 3

[0027] The air-conditioning gas-liquid separator of this embodiment includes a cylinder body 1, an air inlet pipe 2 and an air outlet pipe 4 with a U-shaped pipe 3, the U-shaped pipe 3 is arranged on the outside of the cylinder body 1, and the air outlet pipe 4 and the cylinder body 1 A pressure equalizing tube 5 is arranged between them, and the pressure equalizing tube 5 communicates with the air outlet pipe 4 and the inner cavity of the cylinder body 1. Two oil return holes are set on the air outlet pipe 4, the upper oil return hole 6 and the lower oil return hole 7, the diameter of the upper oil return hole 6 is smaller than the diameter of the lower oil return hole 7, the diameter of the upper oil return hole 6 is 1.2mm, and the lower oil return hole The diameter of the hole 7 is 2.5mm, the distance between the upper oil return hole 6 and the lower oil return hole 7 is 35mm, and the distance between the lower oil return hole 7 and the bottom of the cylinder body 1 is 25mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com