Transplantation control system and transplantation control method for robot for column cultivation

A control system and robot technology, applied in the field of agricultural robots, can solve problems such as complex algorithms, long running time, and complicated path planning problems, and achieve the effect of simplifying calculations, improving flexibility, fast and reliable automatic transplanting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

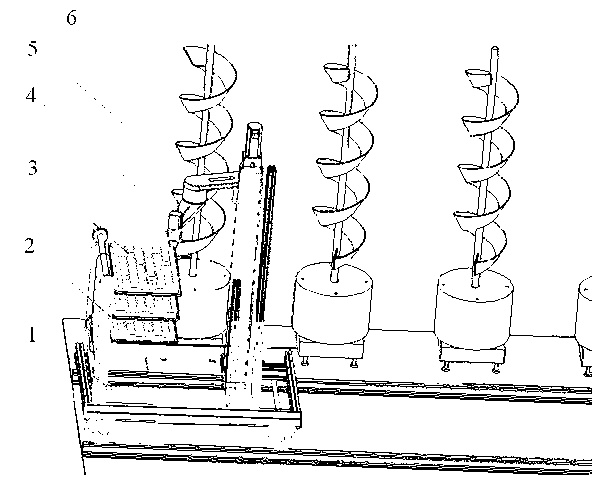

[0031] Such as figure 1 As shown, the supporting transplanting robot for the cultivation column includes an autonomous mobile chassis 1 , a flip-type multi-tray seedling supply device 2 , an end effector 4 and a manipulator 5 . The self-moving chassis 1, the overturned multi-tray seedling supply device 2, and the end effector 4 are respectively driven by motors. Multiple joints of the manipulator 5 are respectively driven by motors. A plurality of cultivation columns 6 can be driven by a motor to rotate around respective axes. The automatic transplanting management of the plug seedlings is performed on a plurality of cultivation columns 6 by a supporting transplanting robot.

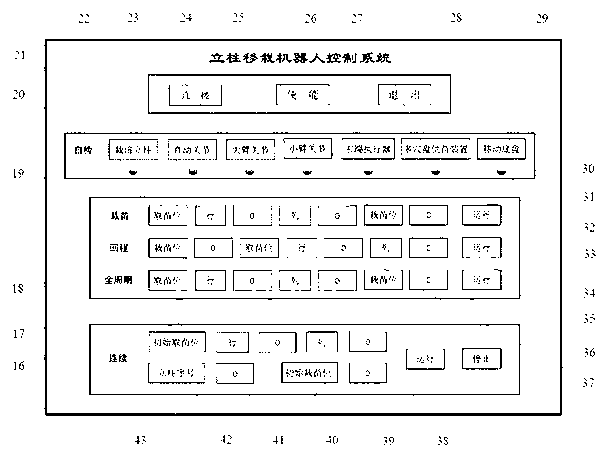

[0032] The column transplanting robot control system includes a control interface 7 , a bottom program 8 and a trajectory library 9 .

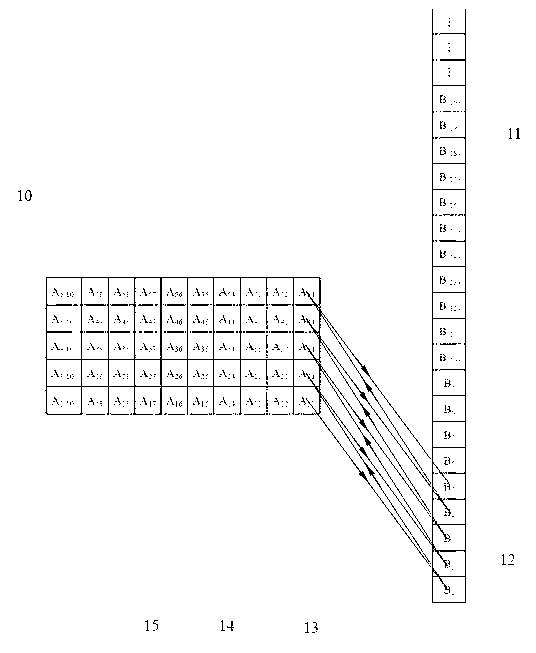

[0033] combine figure 2 , the trajectory library 9 includes the trajectory of the seedling planting stroke 13 from any seedling picking position 10 on the hole tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com