Touch panel, touch-type liquid crystal display panel and forming method thereof

A technology of liquid crystal display panels and touch panels, applied in the field of touch panels and their formation, touch-type liquid crystal display panels and their formation, can solve the problems of complex production process, increase the process of removing explosion-proof film, etc., and achieve the production process Simplicity, small thickness, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

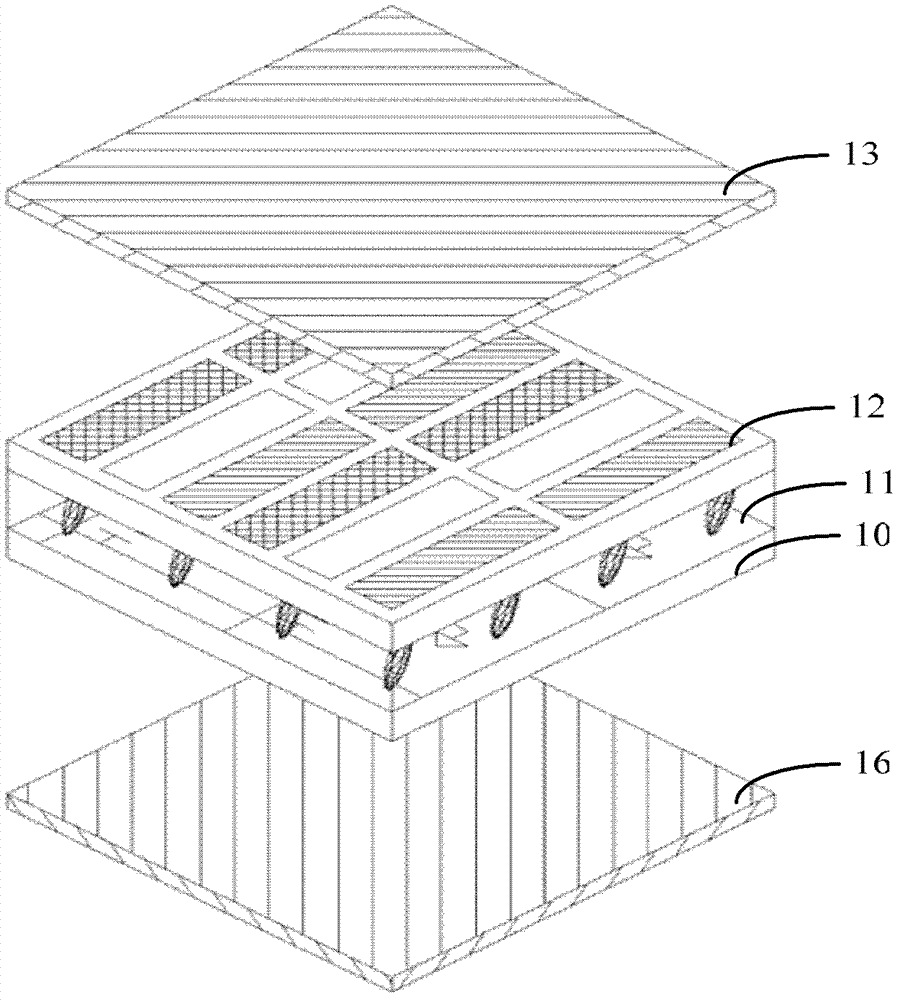

[0110] The present invention also provides a second embodiment of the method for forming a touch-sensitive liquid crystal display panel, specifically:

[0111] Executing step S1: providing a substrate that can function as a cover;

[0112] Executing step S2: setting a touch structure on the substrate to form a full-page touch panel including a plurality of independent touch panels;

[0113] Executing step S3: providing a first polarizer, and attaching the first polarizer to the full-page touch panel;

[0114] Executing step S4: cutting the full-page touch panel to form a plurality of independent touch panels;

[0115] Executing step S5: providing an independent liquid crystal display panel; bonding the independent liquid crystal display panel and the first polarizer on the independent touch panel together to form a touch-sensitive liquid crystal display panel.

[0116] It can be understood that, when cutting the full-page touch panel, the first polarizer is also cut into a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com