Interturn insulating structure of super-thin 6kV high-voltage motor and manufacturing method of interturn insulating structure

A high-voltage motor, inter-turn insulation technology, applied in the shape/style/structure of winding insulation, laying solid insulation and other directions, can solve the problem of inability to reduce thickness, reduce insulation damage, avoid inter-turn short circuit, and avoid hardening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

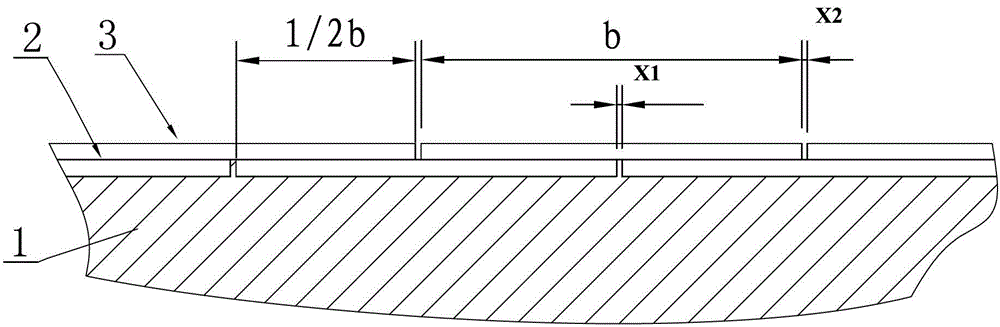

[0031] Such as figure 1 As shown, the present embodiment provides a turn-to-turn insulation structure of a 6kV class high-voltage motor, which includes a wire insulation layer, and the wire insulation layer is made of a two-layer polyester film less rubber mica tape 2 wrapped on a copper flat wire conductor 1, 3 composition.

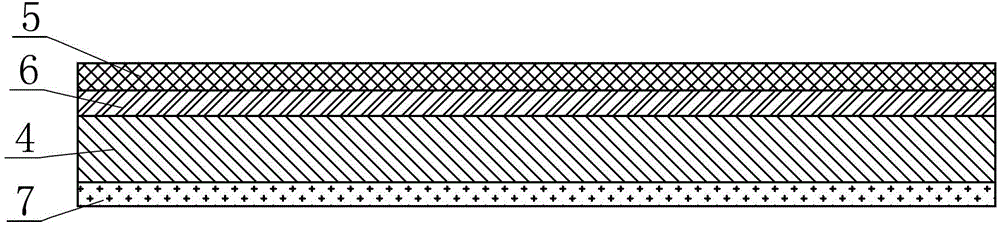

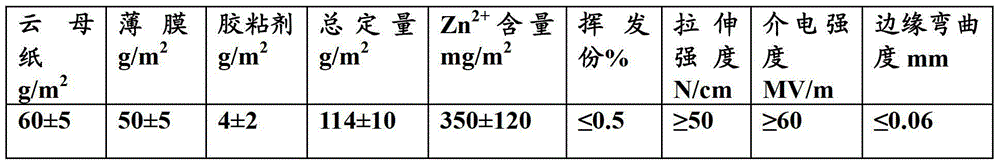

[0032] Such as figure 2 As shown, different from the polyester film less glue mica tape used in the traditional turn-to-turn insulation structure, the polyester film less glue mica tape 2 and 3 used in this embodiment include a polyester film layer 4 and a powder mica paper layer 5 1. In addition to the adhesive layer 6 formed between the polyester film layer 4 and the powder mica paper layer 5, it also includes a self-adhesive glue 7 coated on the reverse side of the polyester film layer 4. Controlling the content of self-adhesive 7 will not only help the discharge of gas and the infiltration of insulating resin during VPI of the motor, but also ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com