Conveyor rollers with movable teeth

A technology of conveying rollers and movable teeth is applied in the field of rollers for conveying sugar cane, which can solve the problems of low leaf peeling efficiency and low cleanliness, and achieve the effects of improving service life, increasing income and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing:

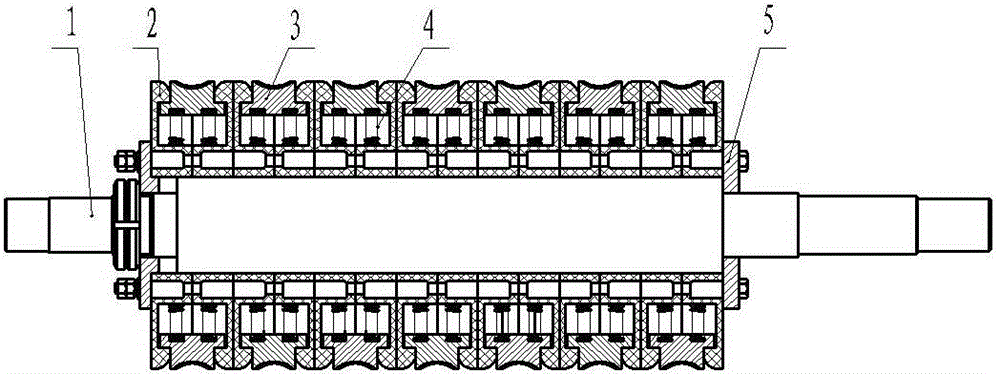

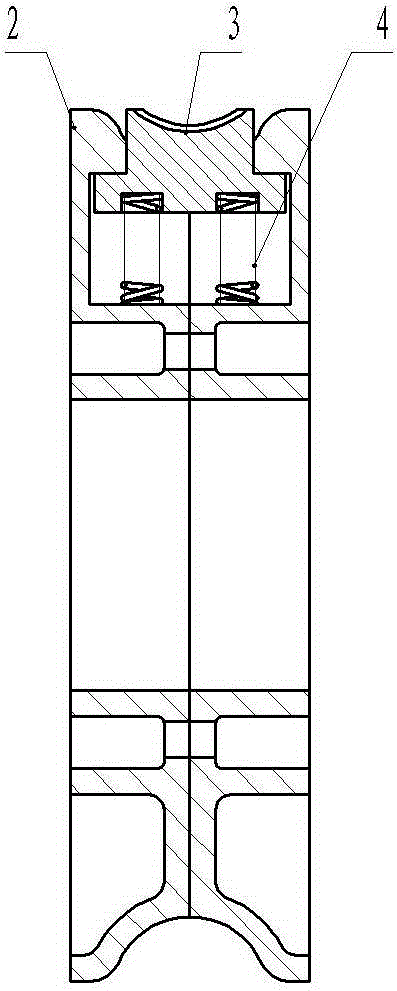

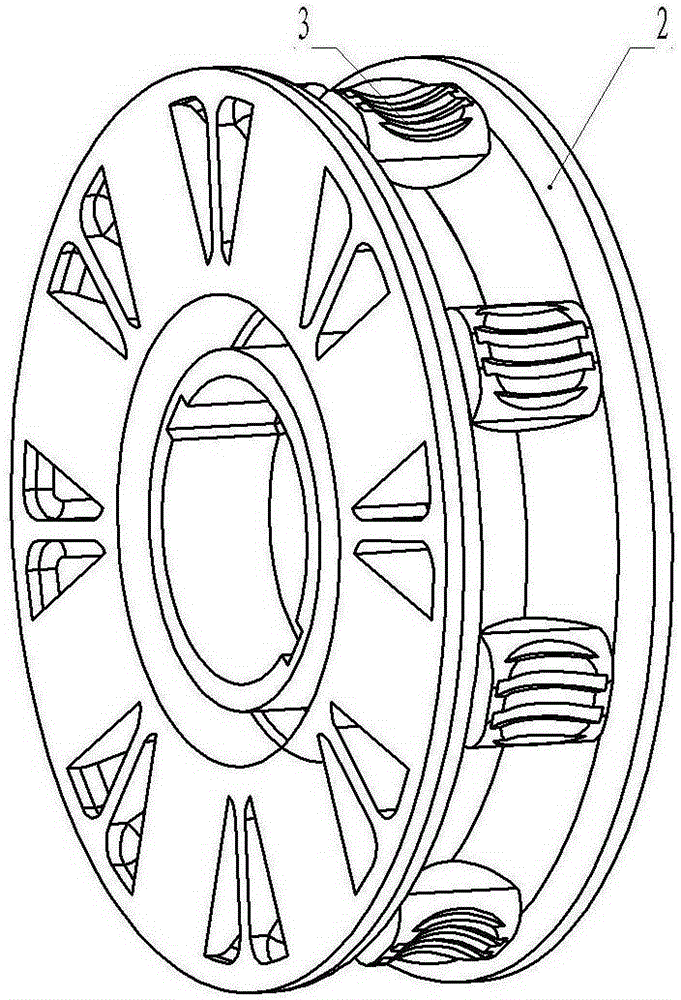

[0016] like figure 1 , 2 and image 3 The conveying roller with movable teeth shown includes a mandrel 1 and seven conveying wheel sets set on the mandrel 1 with ring grooves on the outer edge. The conveying wheel set is composed of two conveying discs 2 connected by bolts. All the conveying wheel groups are fixedly connected with two pressing plates 5 by multiple bolts. Each conveying wheel set in this embodiment is provided with eight radial limit grooves, and each radial limit groove is fitted with a radial tooth 3 that moves in the radial limit groove. The bottom of the radial tooth 3 in the example is provided with two spring positioning holes, and the top of the radial tooth 3 outside the radial limit groove is provided with an arc-shaped groove, and teeth are distributed on the surface of the arc-shaped groove to increase the diameter. The clamping stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com