Gingko powder and preparation method thereof

A preparation method and technology of ginkgo powder are applied in the field of ginkgo processing to achieve the effects of reduced energy consumption, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

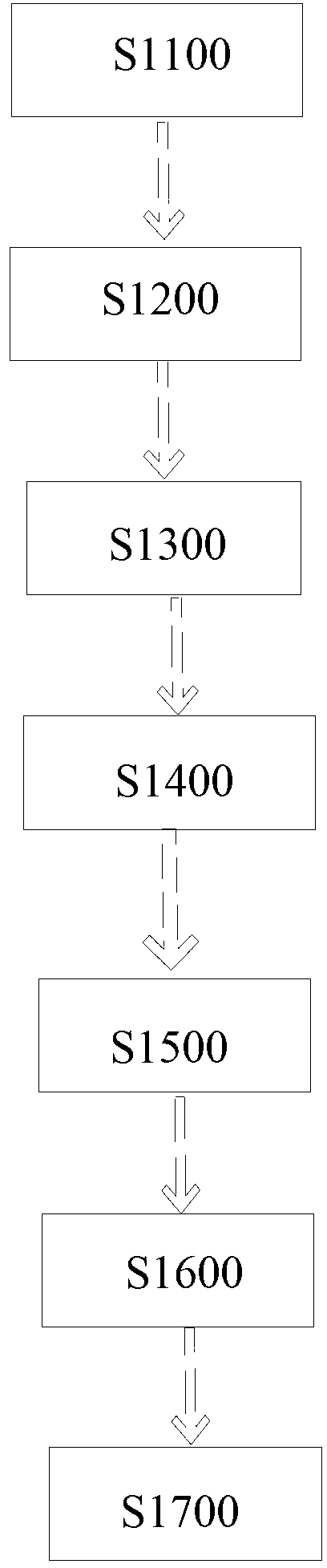

[0027] like figure 1 The shown ginkgo powder preparation method according to a preferred embodiment of the present invention, the preparation method of the ginkgo powder provided by the present invention includes the steps: first enter the step S1100 of obtaining ginkgo nuts, then enter the step S1200 of roasting and frying the ginkgo nuts, Step S1300 of roasting ginkgo kernels, removing peel S1400, drying ginkgo kernels S1500, crushing ginkgo kernels S1600, and finally entering step S1700 of grinding ginkgo powder.

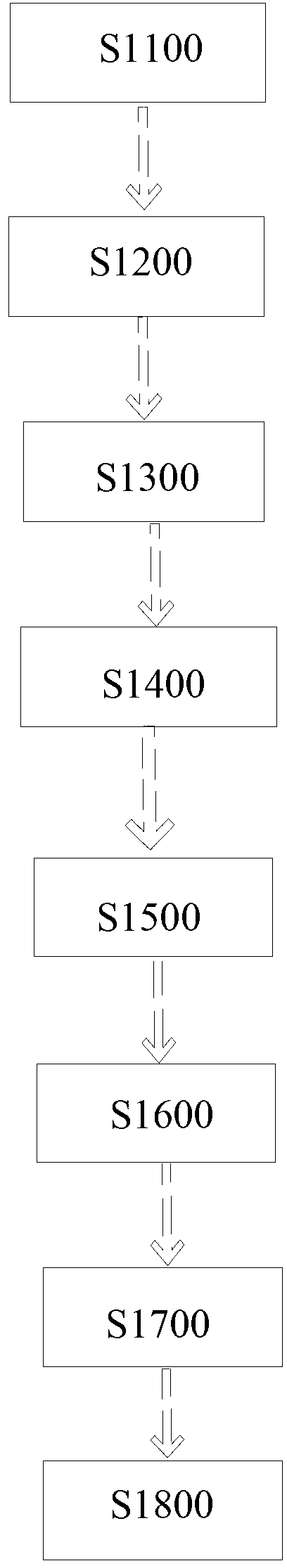

[0028] In order to increase the flavor of the ginkgo powder prepared by the present invention and increase the nutritional content of the ginkgo powder to meet the needs of different groups for the ginkgo powder, the preparation method of the present invention further includes the step of adding auxiliary materials to the ginkgo powder. like figure 2 As shown, the preparation method of the ginkgo powder provided by the present invention includes the steps: firs...

Embodiment 1

[0031] like figure 1 The shown ginkgo powder production method according to a preferred embodiment of the present invention first enters the step S1100 of obtaining ginkgo nuts: peeling, washing and drying the ginkgo nuts and taking out the ginkgo nuts. Then enter the step S1200 of roasting the ginkgo nuts: roasting the ginkgo nuts at a temperature of 100° C. for 1 hour, and then taking out the ginkgo nuts. Next, enter the step S1300 of roasting the ginkgo kernels: removing the ginkgo buds, and roasting the ginkgo kernels at 60° C. for 40 minutes. Then remove the pericarp S1400: remove the pericarp in the ginkgo kernel by wind blowing. Then enter the step S1500 of drying the ginkgo kernels: drying the ginkgo kernels at 60° C. for 5 hours, and then at 40° C. for 5 hours. Then enter the ginkgo kernel crushing step S1600: crush the dried ginkgo kernels into granules. Finally enter the step S1700 of grinding ginkgo powder: Grinding granular ginkgo kernels to make ginkgo kernel ...

Embodiment 2

[0033] like figure 1 The shown ginkgo powder production method according to a preferred embodiment of the present invention first enters the step S1100 of obtaining ginkgo nuts: peeling, washing and drying the ginkgo nuts and taking out the ginkgo nuts. Then enter the step S1200 of roasting the ginkgo nuts: roasting the ginkgo nuts at a temperature of 150° C. for 40 minutes, and then taking out the ginkgo nuts. Next, enter the step S1300 of roasting the ginkgo kernels: removing the ginkgo buds, and roasting the ginkgo kernels at 80° C. for 30 minutes. Then enter the step of removing the peel S1400: remove the peel of the ginkgo kernels by blowing the wind. Then enter the ginkgo kernel drying step S1500: dry the ginkgo kernel at 80° C. for 3 hours, and then at 50° C. for 3 hours. Then enter the step S1600 of crushing the ginkgo kernels: crush the dried ginkgo kernels into granules. Finally enter the step S1700 of grinding ginkgo powder: Grinding granular ginkgo kernels to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com