Variable-frequency ultrasonic system based on digital pulse driving

A frequency-conversion ultrasonic and digital pulse technology, applied in the direction of using vibrating fluids, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of little significance and no frequency-adjustable transducers, etc., to achieve strong power and satisfy Design requirements, the effect of continuously adjustable power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Attached below figure 1 ~ attached Figure 8 The present invention is described in detail below.

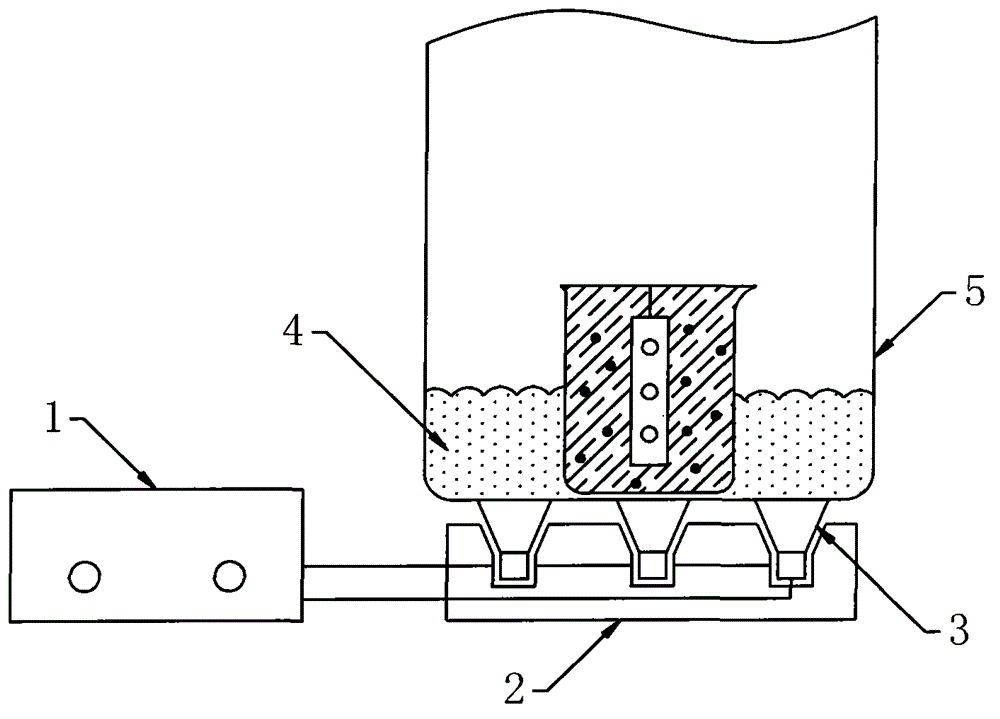

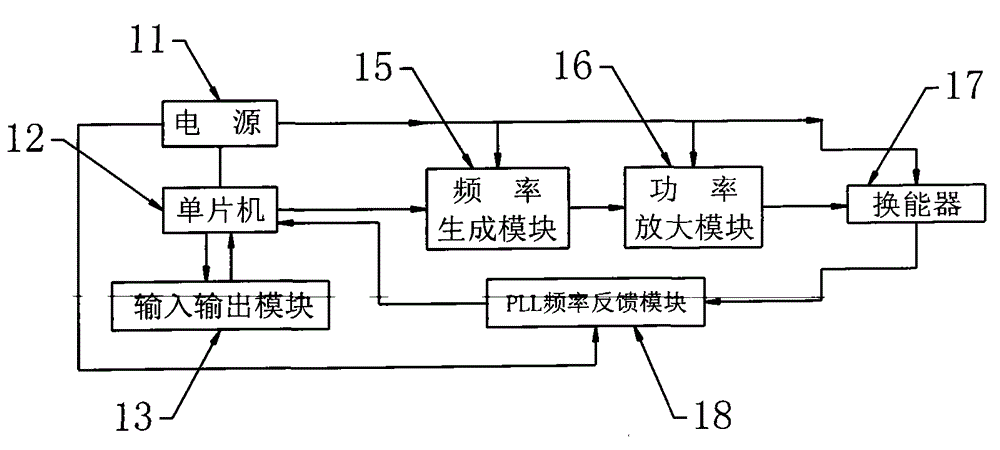

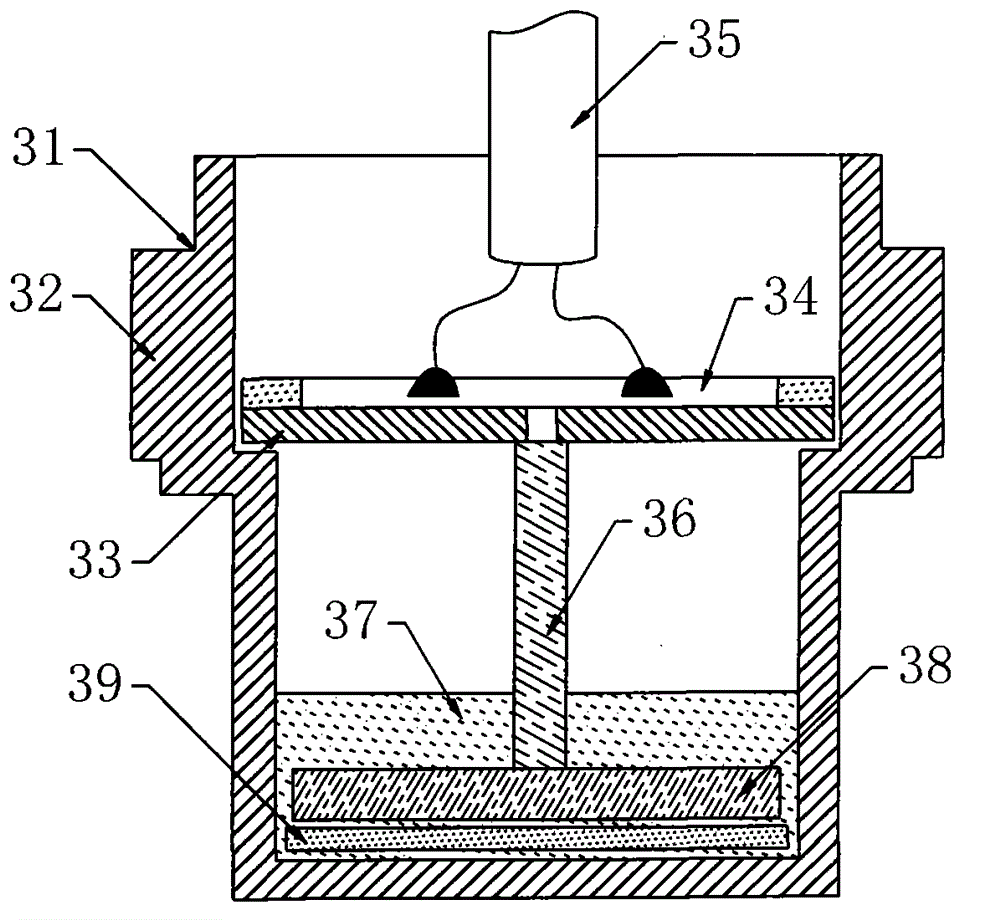

[0046] Such as Figure 1 to Figure 8 Shown, the present invention comprises ultrasonic generator 1, ultrasonic transducer 3 and ultrasonic wave field effect groove 5; Ultrasonic generator 1 is the frequency conversion ultrasonic generator based on DDS technology, comprises power supply 11, single-chip microcomputer 12, frequency generating module 15, Power amplifying module 16, PLL frequency feedback module 18 and input and output module 13; Ultrasonic transducer 3 is the transducing module group that multiple groups of ultrasonic transducing units are formed, and ultrasonic transducing unit comprises piezoelectric sheet 38, conductive glue 39, Sound-absorbing material 37, conductive column 36, wiring board 33, retaining ring 34 and shell 31; ultrasonic transducer 3 is fixed on the base 2, and is electrically connected with ultrasonic generator 1, and described ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com