Cleaning method and cleaning device for ink wiping roller of gravure press

A technology for cleaning devices and gravure printing machines, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of low utilization rate of ink wiping cleaning liquid, excessive leakage of cleaning liquid, severe cleaning liquid rejection, etc. Achieve the effect of reducing the consumption of chemicals and water resources, saving cleaning fluid, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

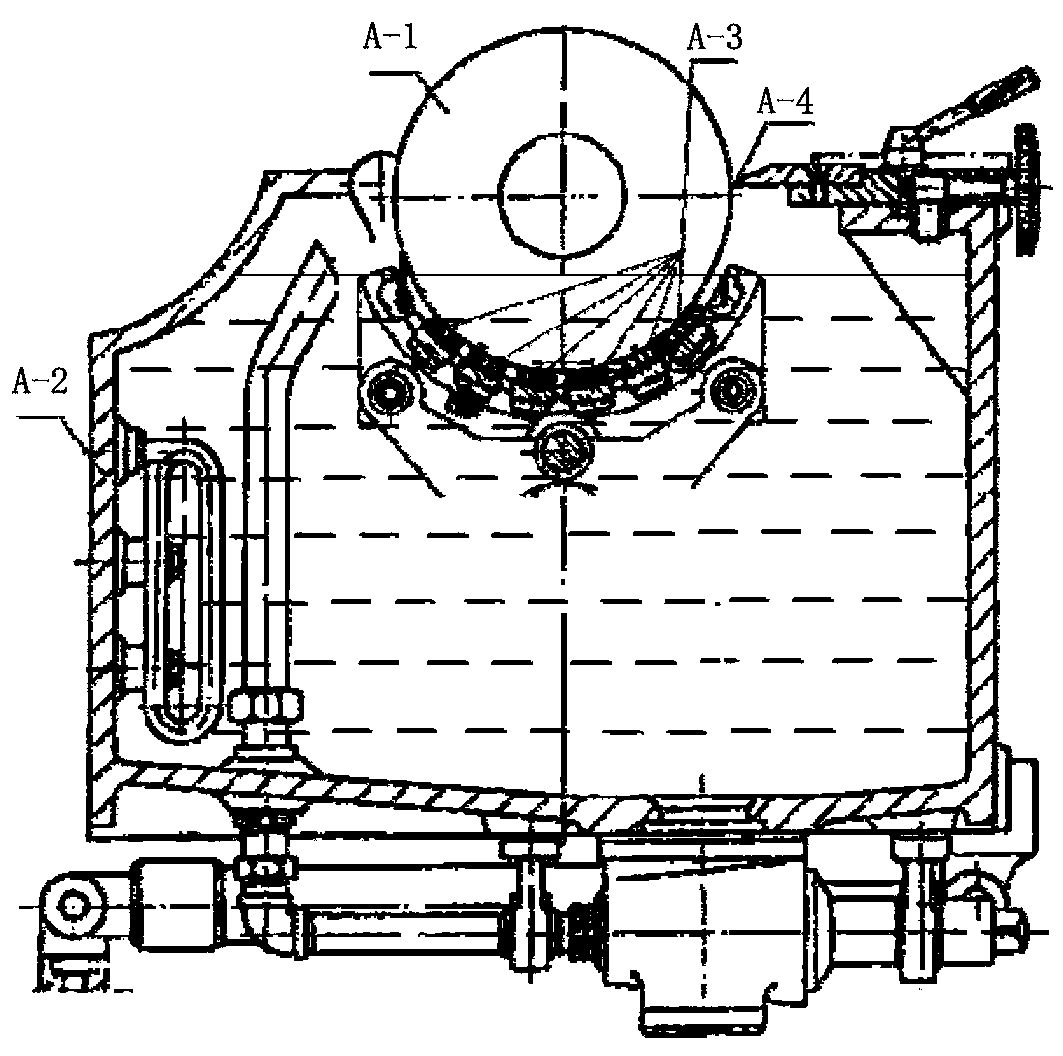

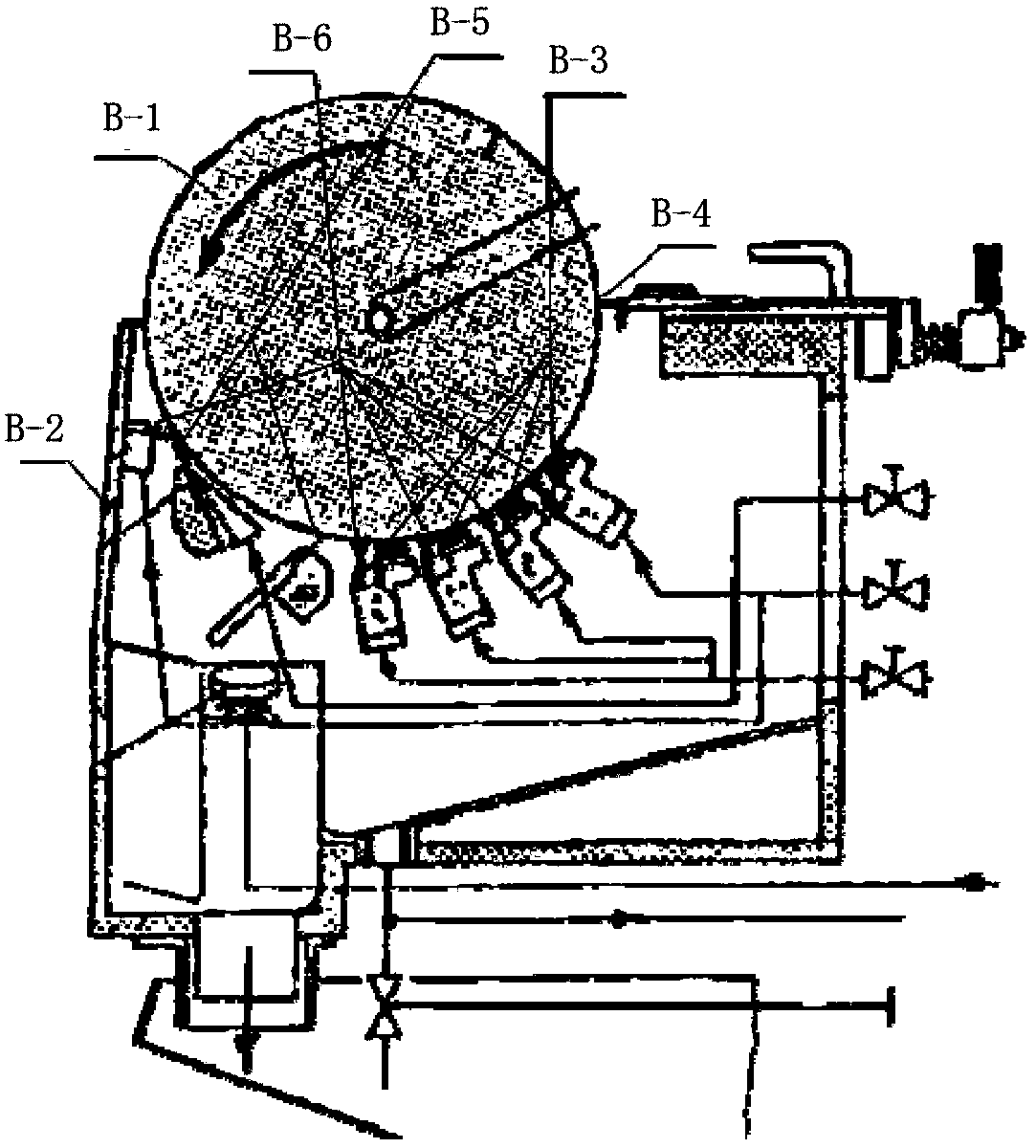

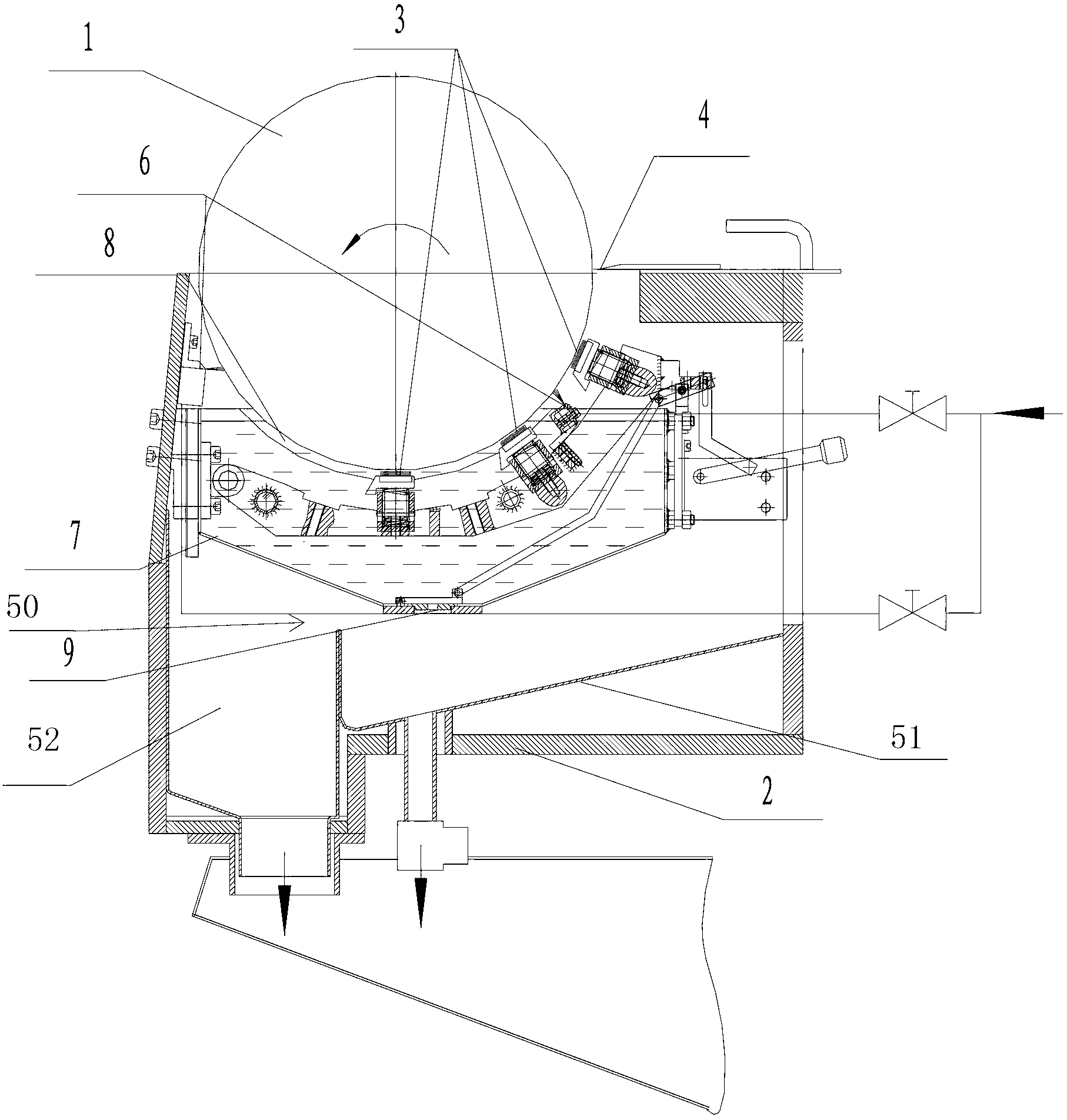

[0027] The invention proposes a method and device for cleaning ink wiping roller of a hybrid gravure printing machine. The cleaning device includes a scraper and a brush arranged on the lower side of the wiping roller, and the cleaning device includes a spraying device arranged in a wiping box. structure and soaking structure; the spray structure can spray cleaning liquid to the ink wiping roller, and the cleaning liquid flows into the soaking structure, so as to continue soaking and wiping the cylindrical surface of the ink wiping roller to form a hybrid cleaning device for the ink wiping roller . The cleaning method includes: spraying ink wiping, spraying cleaning liquid to the cylindrical surface of the ink wiping roller body through a cleaning liquid spray rod, and wiping the cylindrical surface of the ink wiping roller with a wiping brush; soaking ink wiping, The cleaning liquid in the spray cleaning step flows into an inner soaking structure, and maintains a predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com