Single-wheel cycled multi-car elevator

A multi-car and car technology, applied in the field of multi-car elevators, can solve the problems of low operation efficiency, car overturning, not considering the problem of track turnout, etc. The effect of shortening the waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

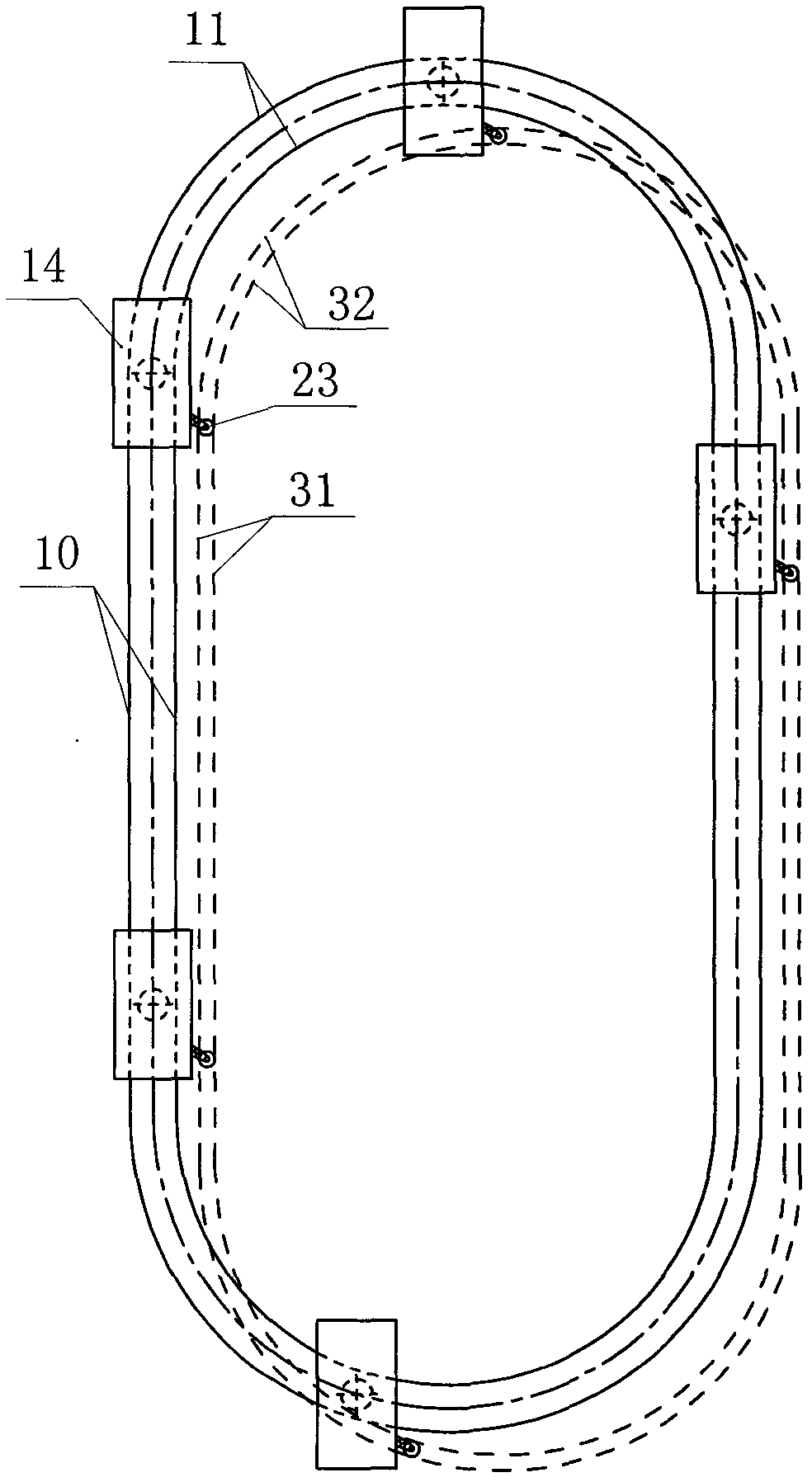

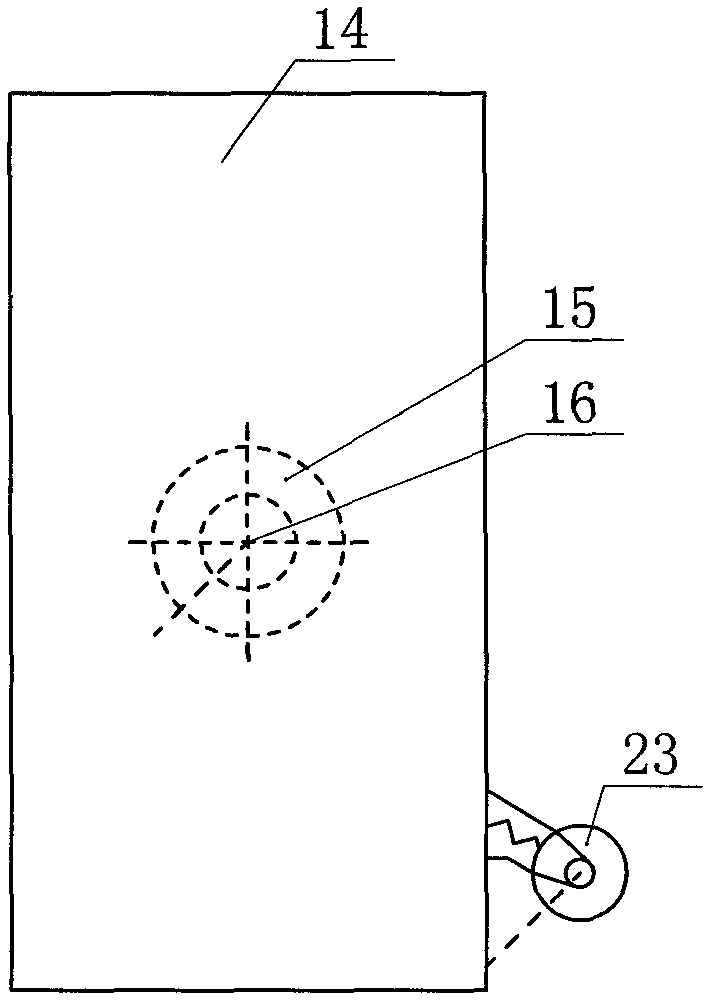

[0021] Such as Figure 1~3 As shown, a circular multi-car elevator includes a car 14, a drive mechanism, and a car positioning rail. The car 14 is provided with a car wheel 23, and the car wheel 23 is arranged in the car wheel positioning rail. , the car wheel positioning rail comprises a vertical section 31 of the car wheel positioning rail and a curved section 32 of the car wheel positioning rail. It includes a car positioning rail vertical section 10 and a car positioning rail curved section 11.

[0022] In this embodiment, the vertical section 10 of the car positioning rail and the curved section 11 of the car positioning rail form a circular closed car positioning rail, and the driving mechanism drives the car 14 to move along the car positioning rail, and the car Wheel 23 runs along the car wheel alignment rail all the time, can guarantee that car can not overturn in running process. In addition, several cars can exist in the car positioning rail at the same time, ther...

Embodiment 2

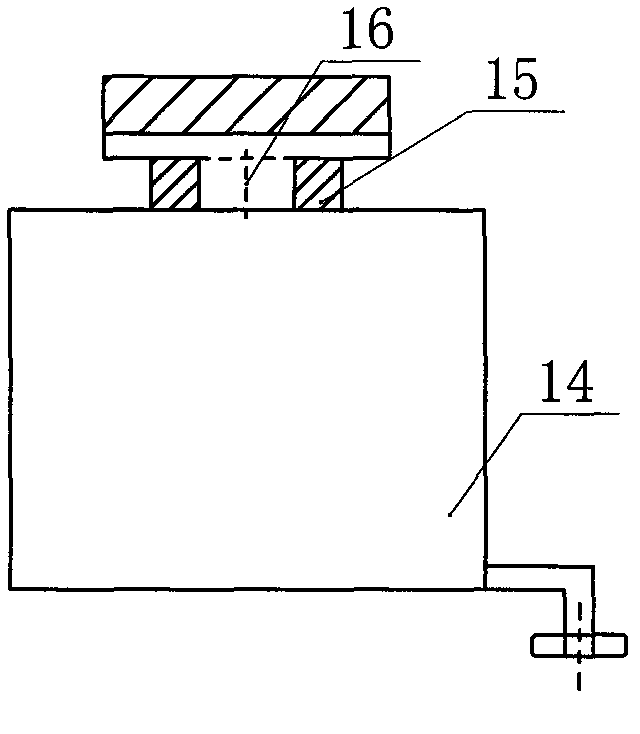

[0024] Such as Figure 4~7 As shown, the driving mechanism includes a driving power source and driving car I 35a, driving car II 35b, driving car III 35C, between driving car I 35a and driving car II 35b, between driving car II 35b and driving car III 35C Connected by a ball chain device 37, the car 14 is connected with the driving trolley II 35b through the connecting shaft 16 and the turntable 15, and the driving trolley II 35b is provided with a brake 38. The brake 38 is arranged on both sides of the driving trolley 35b, and uses the top surface of the car positioning rail as the braking surface to realize the braking of the car 14. A primary armature 34b is provided on each driving trolley. When the winding in the primary armature 34b is energized, a traveling magnetic field is formed, which interacts with the permanent magnetic field generated by the permanent magnet 34a to generate lifting force and drive the car 14 to run.

[0025] Wherein, the driving power source inc...

Embodiment 3

[0029] Such as Figure 8-9 As shown, two sets of primary armatures 34b are arranged on the connecting plate 41 of the positioning wheel group, two sets of permanent magnets 34a are arranged on the fixed part of the power source, brake rails 43 are arranged between the two sets of permanent magnets 34a, and the brake 38 is arranged on on the brake rail 43. Other structures are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com