Rope locker

A rope locker and mainboard technology, applied in the field of rope lockers, can solve problems such as wire ropes not being firmly fixed, and achieve the effects of easy selection, cumbersome operation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

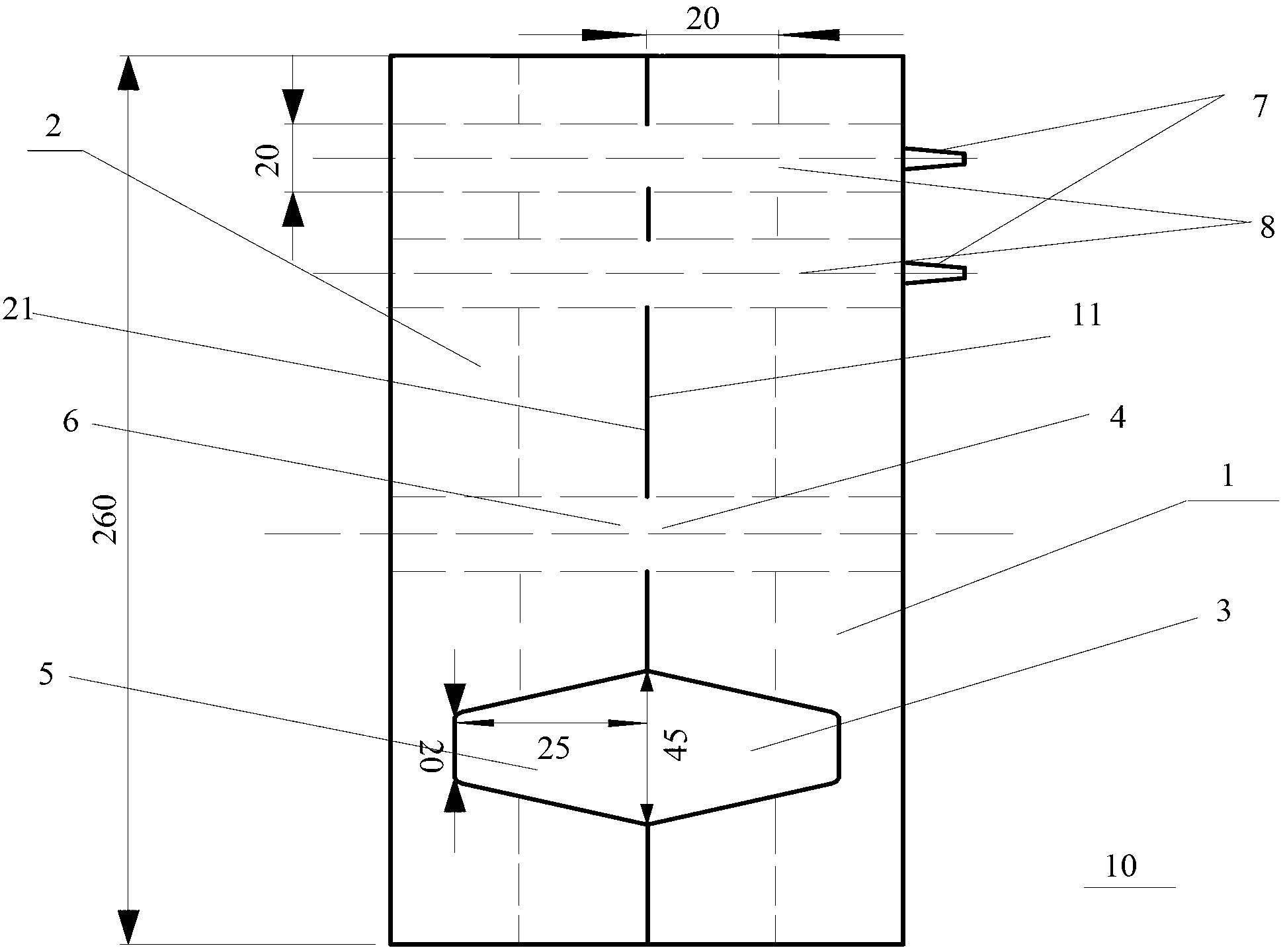

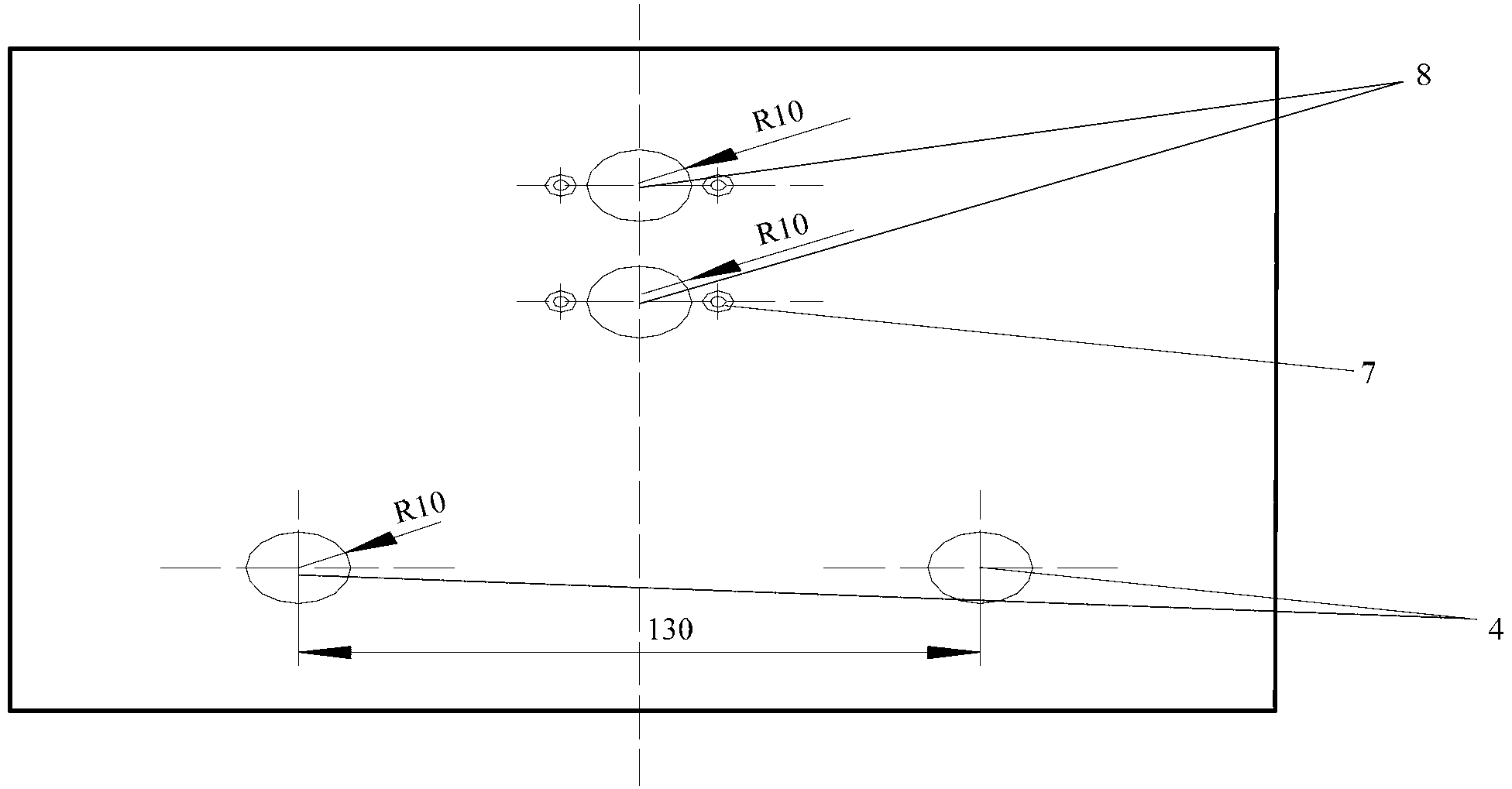

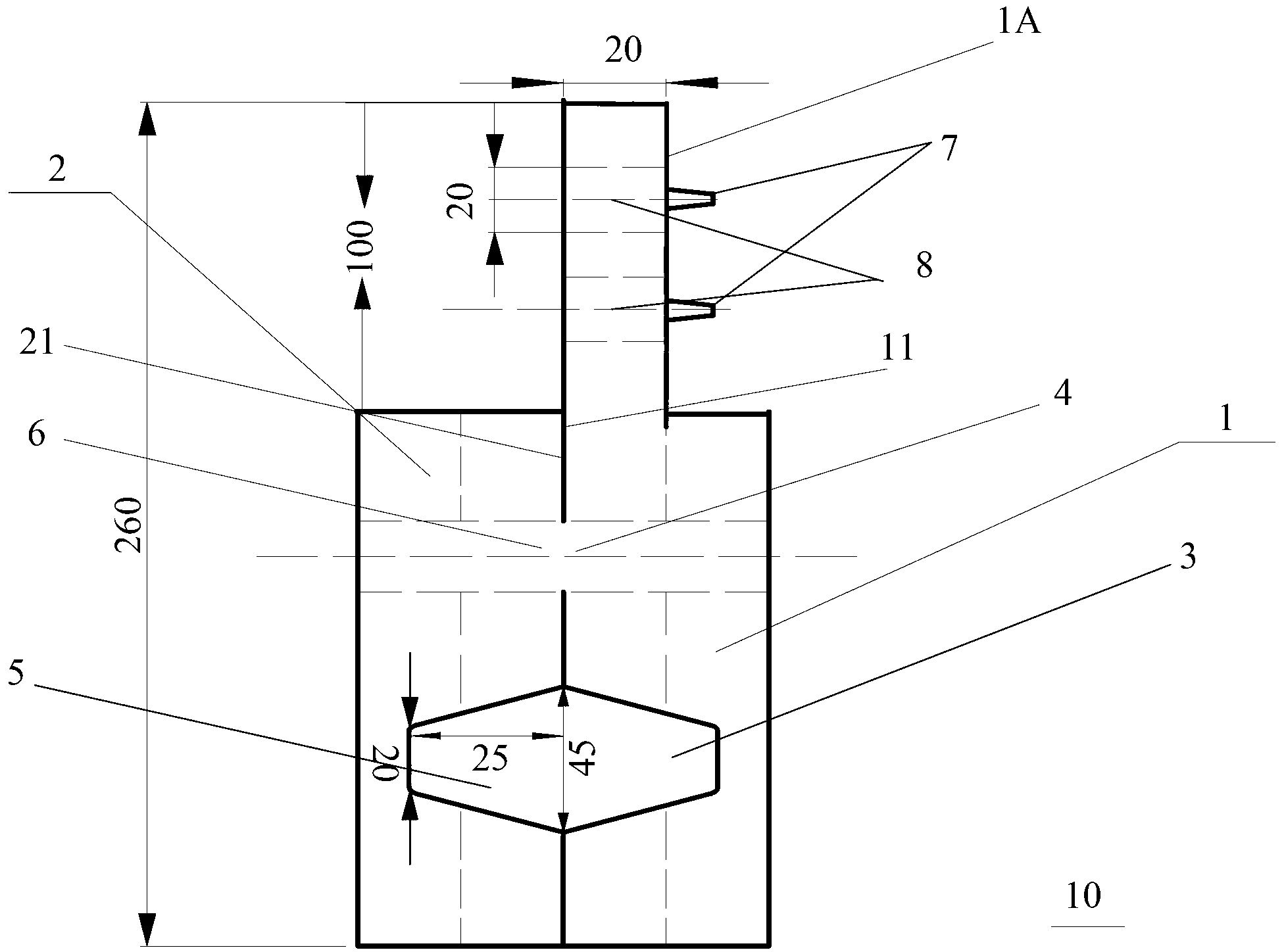

[0030] figure 1 It is a schematic cross-sectional structure diagram of Embodiment 1 of the rope lock device of the present invention. figure 2 for figure 1 The right side view of the upper part of the first embodiment shown. Such as figure 1 As shown, the section of the rope locker is a section perpendicular to the extending direction of the track. The rope locker 10 of this embodiment includes: a main board 1 and a sub-board 2; the bottom of the first surface 11 of the main board 1 is provided with a first groove 3 and the upper part of the first surface 11 is provided with the first fixing hole 4, the lower part of the first surface 21 of the sub-board 2 is correspondingly provided with the second groove 5, and the upper part of the first surface 21 of the sub-board 2 is correspondingly provided with the second Fixing hole 6; when the first surface 11 of the main board 1 and the first surface 21 of the sub-board 2 are attached to the track, the first groove 3 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com