Formwork creeping method for novel 1.6 parabola-shaped four-column type hollow variable section high pier

A parabolic, column-slab type technology, which is applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve various problems in installation, reinforcement or deviation correction, troublesome completion of bridge construction, difficult control of formwork linear structure, etc. , to achieve the effects of flexible assembly, shortened construction period, and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

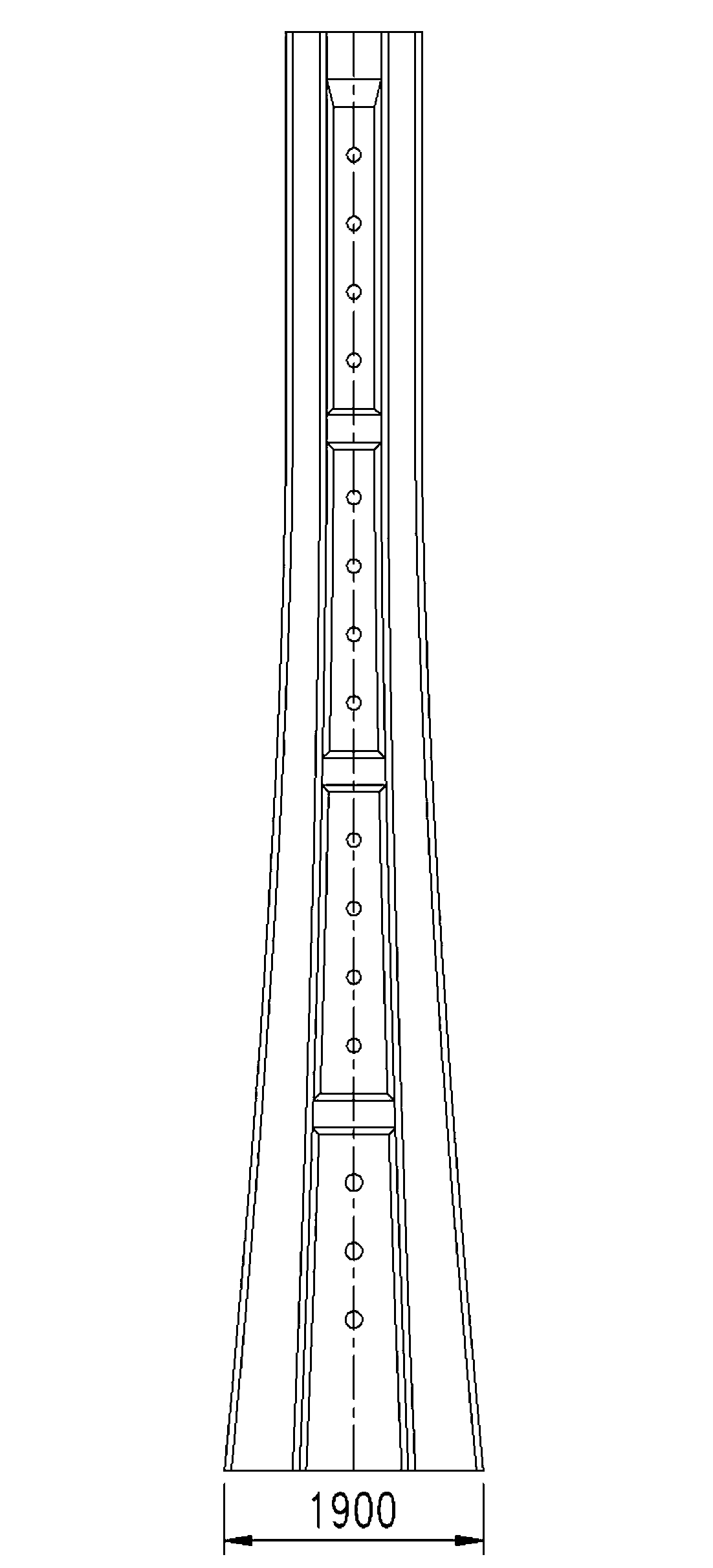

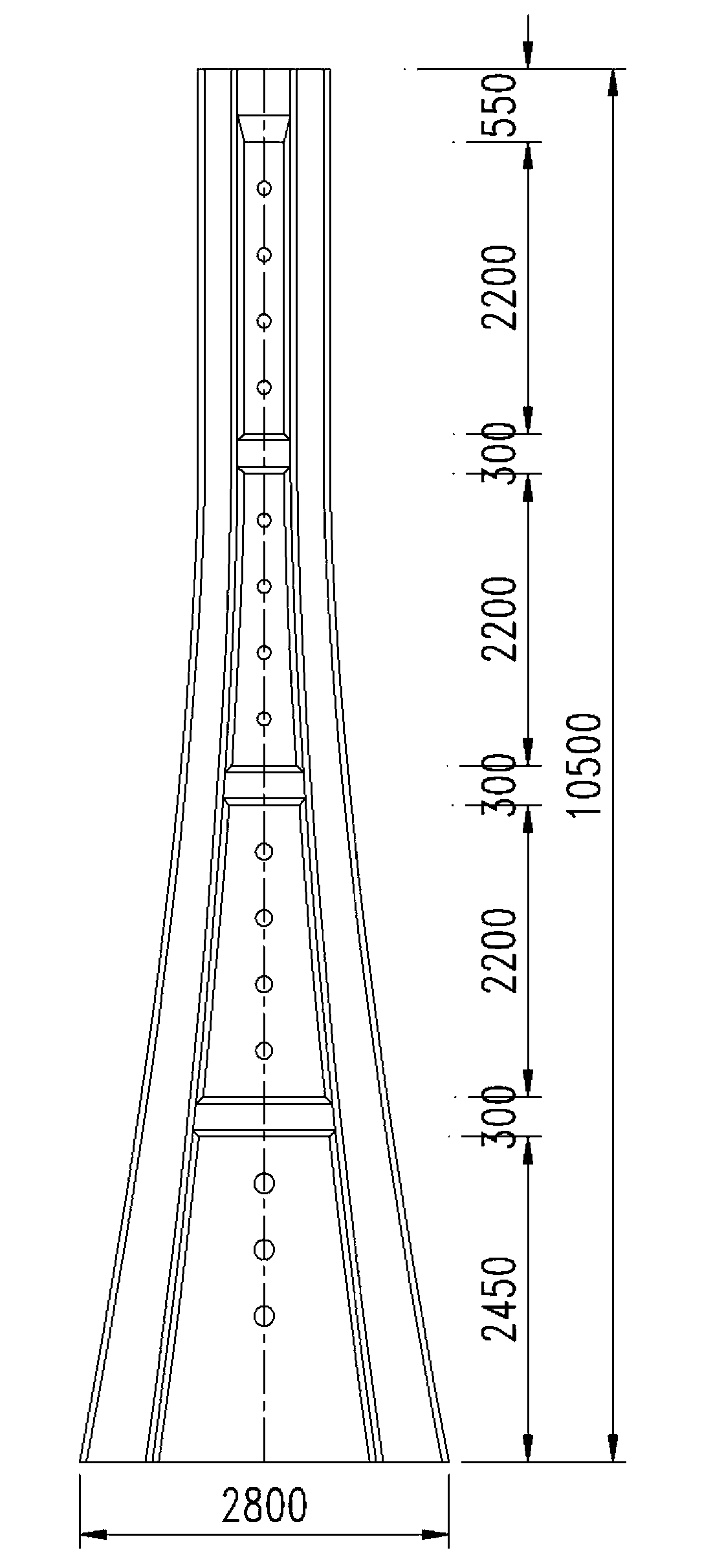

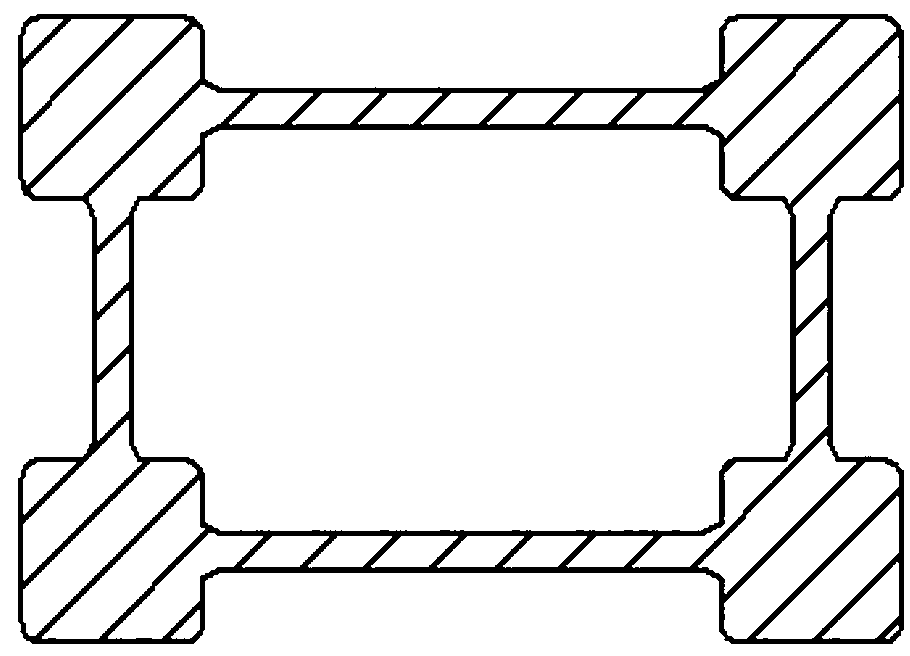

[0021] see Figure 1-3 The 1.6-degree parabola-shaped new column-slab-type hollow high pier, the pier body is composed of 4 variable-section columns, the top 30m of the column is in a straight line, and the lower part 75m is arranged according to the 1.6-degree parabola in the longitudinal and transverse bridge directions, and reinforced concrete is set between the columns. The plates are interconnected to form a rectangular thin-walled structure.

[0022] see Figure 4-7 According to the installation method of the bridge pier formwork, climb according to this installation method. The climbing process is: after the first concrete pouring, remove the formwork and support; clean up the sundries on the surface of the formwork; hoist the climbing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com