Reinforced concrete pipe lattice column

A technology for reinforced concrete pipes and reinforced concrete columns, which is applied in the field of reinforced concrete pipe lattice columns, can solve problems such as damage and failure of lattice columns, and achieve the effects of improving bearing capacity, restraining deformation, and reducing the self-weight of the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

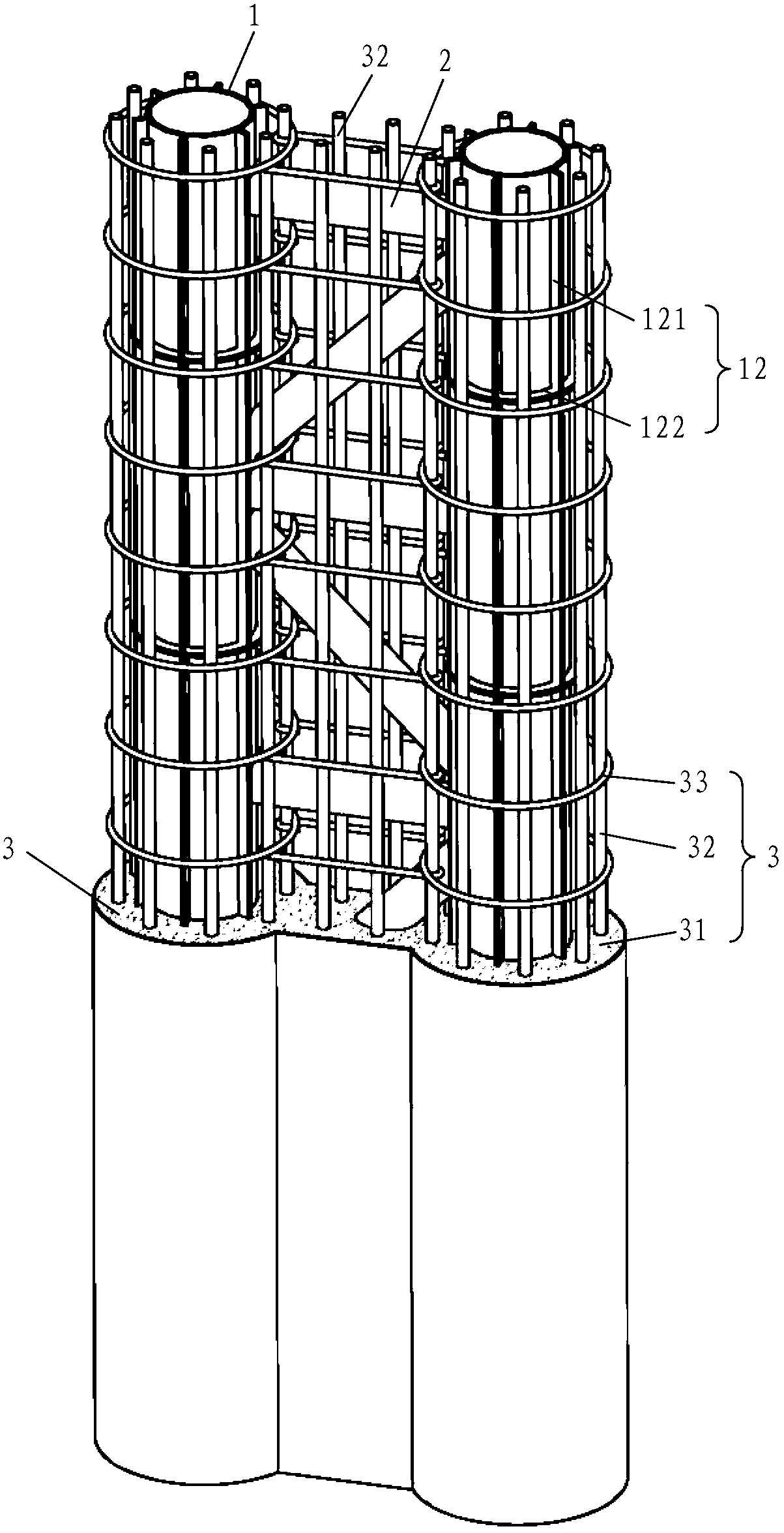

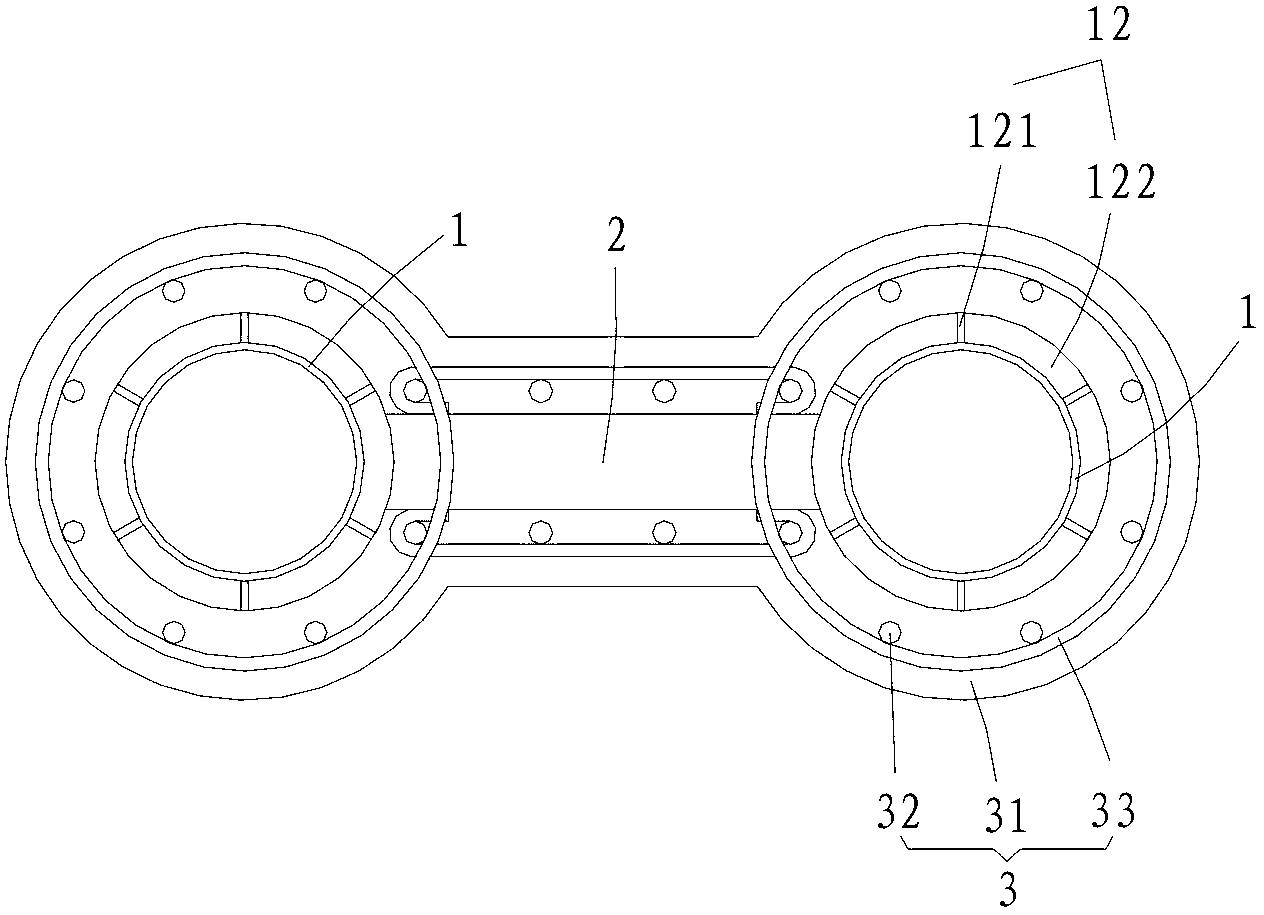

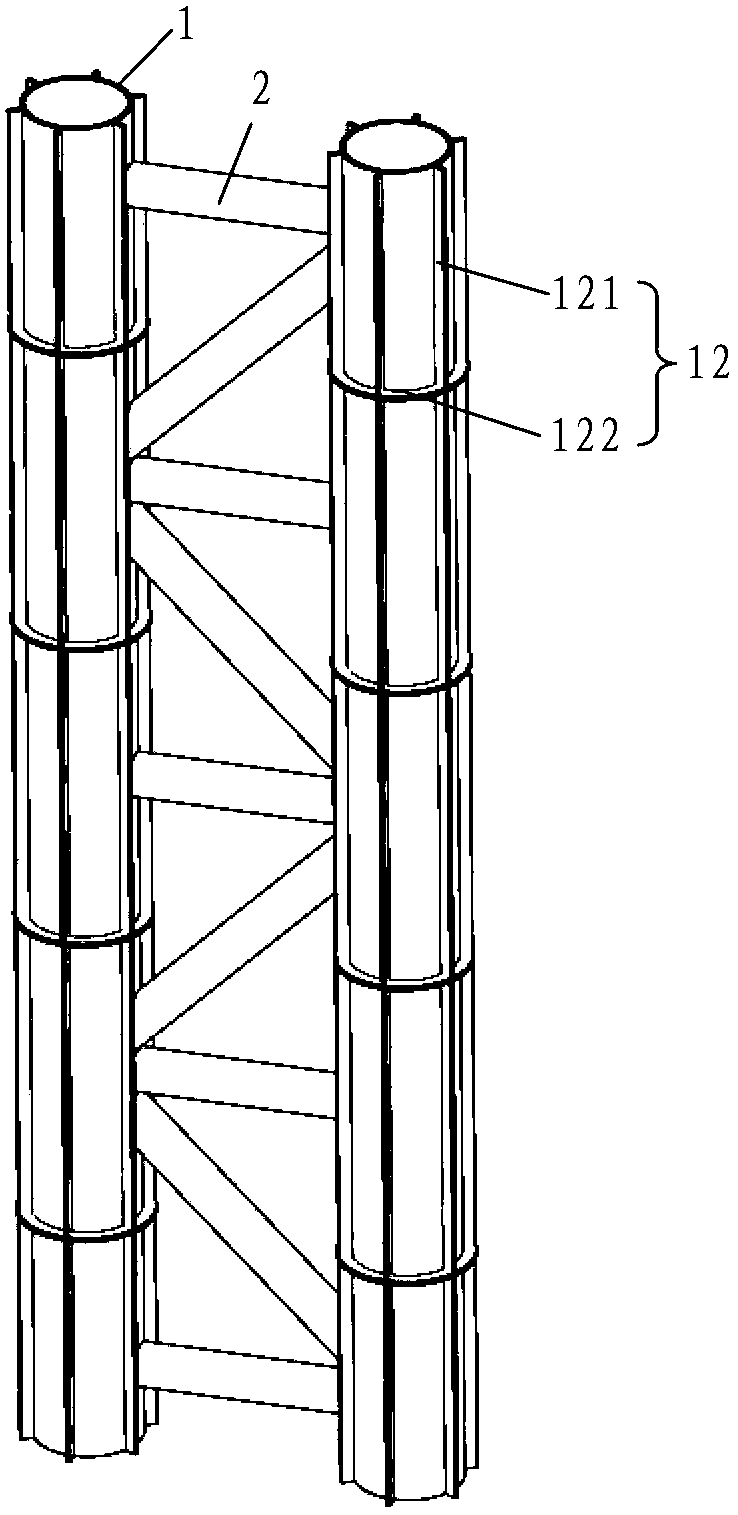

[0020] see Figure 1 to Figure 3 As shown, the reinforced concrete tubular lattice column of the present invention includes at least two hollow tubular columns 1, and each hollow tubular column 1 is at least connected to an adjacent hollow tubular column 1 through a web bar 2, and the periphery of the hollow tubular column 1 is also Cover a reinforced concrete column 3 . figure 1 The embodiment shown comprises two hollow pipe strings 1, and two hollow pipe strings 1 are connected by web rod 2, if comprise 3 or more than 3 hollow pipe strings 1 in other embodiments, each hollow pipe string 1 can be connected with one or Multiple adjacent hollow pipe strings 1 are connected by web rods 2, so that the overall strength of the hollow pipe string 1 is better.

[0021] The outer wall of the hollow column 1 is provided with a plurality of stiffening ribs 12 . The stiffeners 12 include intersecting longitudinal stiffeners 121 and circumferential stiffeners 122, the longitudinal stiff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com